Product Description

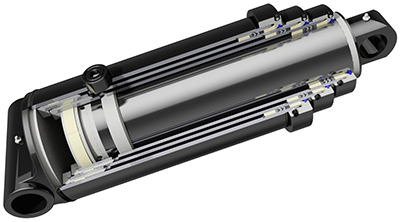

| Customized Single Double Acting Telescopic Hydraulic Cylinder | |||

| Part number | Tube dia mm | Rod dia mm | Stroke mm |

| 205-63-57100 | 120 | 85 | 1285 |

| 206-63-57100 | 120 | 85 | 1285 |

| 205-63-57160 | 120 | 85 | 1285 |

| 205-63-57120 | 135 | 95 | 1490 |

| 203-63-57130 | 125 | 85 | 1120 |

| 203-63-57131 | 125 | 85 | 1120 |

| 205-63-57130 | 125 | 85 | 1120 |

Specifications

1.Supply to USA,Europe,and Australia, Russia.

2.Material:Stainless Steel

3.Professional performance excavator parts supplier

4. High quality and low price

FAQ

Q1: Are you Manufacture or Trade Company?

A1: We are manufacture,we have 20 years experience for supply Metal material and products in domestic.

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: What is your terms of payment ?

A3: 1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.CHINAMFG negotiation

Q4: Can you provide Certificates for aluminum materials ?

A4:Yes,we can supply MTC-Material Test Certificate.

Q5: Can you provide sample?

A5: Yes, we can provide you sample, but you need to pay for the sample and freight firstly. We will return the sample fee after

you make an order.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Piston Cylinder |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

Can telescopic cylinders be used in material handling equipment for reach and lift?

Yes, telescopic cylinders are commonly used in material handling equipment to provide reach and lift capabilities. Here’s a detailed explanation:

Role in material handling:

Telescopic cylinders play a crucial role in material handling equipment by extending the reach and enabling the lifting of heavy loads. These cylinders are typically employed in equipment such as forklifts, telehandlers, reach stackers, and aerial work platforms.

Reach extension:

Telescopic cylinders allow material handling equipment to extend their reach by extending the boom or lifting arm. The nested design of the cylinder, with multiple stages that retract inside one another, enables the equipment to achieve a longer reach when required. By extending the telescopic cylinder, operators can access materials at greater heights or reach into confined spaces.

Lifting capacity:

Telescopic cylinders provide the necessary lifting force to handle heavy loads in material handling equipment. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and ensure safe and efficient load handling.

Precision control:

Telescopic cylinders offer precise control over the extension and retraction of the lifting arm or boom. The hydraulic control system regulates the flow of hydraulic fluid to each stage of the cylinder, allowing for smooth and controlled movement. This precise control is essential in material handling applications to ensure accurate positioning of loads and safe operation.

Compactness and flexibility:

Telescopic cylinders contribute to the compactness and flexibility of material handling equipment. By retracting the cylinder stages, the overall length of the equipment can be minimized, making it easier to maneuver in tight spaces. Additionally, the ability to extend and retract the telescopic cylinder provides flexibility in adjusting the reach and adapting to different working conditions.

Variety of material handling equipment:

Telescopic cylinders are utilized in a wide range of material handling equipment to enhance reach and lift capabilities. Forklifts, for example, often incorporate telescopic cylinders to extend the forks and reach into pallet racks. Telehandlers and reach stackers utilize telescopic cylinders to extend the lifting arm and reach high stacking heights. Aerial work platforms utilize telescopic cylinders to extend the platform and provide elevated access for maintenance or construction tasks.

Advantages of telescopic cylinders in material handling:

Telescopic cylinders offer several advantages in material handling equipment:

- Increased reach: Telescopic cylinders allow operators to extend the equipment’s reach, enabling access to materials at greater heights or in confined spaces.

- Enhanced lifting capacity: Telescopic cylinders provide the necessary lifting force to handle heavy loads, expanding the equipment’s lifting capabilities.

- Precision and control: The hydraulic control system of telescopic cylinders allows for precise and controlled movement, ensuring accurate load positioning and safe operation.

- Compactness and flexibility: By retracting the cylinder stages, material handling equipment can be more compact and maneuverable, adapting to different working environments.

Overall, telescopic cylinders are widely used in material handling equipment to extend reach and enhance lifting capabilities. Their precise control, compactness, and flexibility make them essential components in various material handling applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

How do telescopic cylinders contribute to stable and safe equipment operation?

Telescopic cylinders play a significant role in ensuring stable and safe equipment operation. Here’s a detailed explanation:

Load distribution:

Telescopic cylinders assist in distributing the load evenly across the equipment. As the cylinders extend or retract, they provide support and help maintain the balance of the load. This load distribution is crucial for preventing equipment instability, reducing the risk of tipping or tilting, and ensuring safe operation.

Weight management:

Telescopic cylinders aid in managing the weight distribution of equipment during various operations. By extending or retracting the cylinders selectively, operators can control the positioning and center of gravity of the load. This helps mitigate the risk of equipment imbalance, enhances stability, and promotes safe equipment operation.

Controlled movements:

Telescopic cylinders enable controlled and precise movements of equipment components. The hydraulic control system regulates the extension and retraction of the cylinders, allowing operators to adjust the speed, force, and position of the movement. This precise control minimizes sudden or jerky motions, reduces the likelihood of equipment instability, and enhances overall safety during operation.

Shock absorption:

Telescopic cylinders provide a level of shock absorption during equipment operation. The design of the cylinders, along with the hydraulic system, helps absorb and dampen sudden shocks or impacts that may occur during material handling or terrain traversal. This shock absorption capability reduces stress on the equipment, minimizes the risk of component failure or damage, and contributes to safe and smooth operation.

Operator safety:

Telescopic cylinders contribute to operator safety by providing stability and control. The stable operation of equipment facilitated by the cylinders reduces the risk of accidents or operator injury caused by equipment instability, tipping, or excessive vibrations. Additionally, the precise control over equipment movements enhances operator confidence and minimizes the likelihood of human error during operation.

Monitoring and feedback:

Telescopic cylinders can be integrated with monitoring systems that provide real-time feedback on cylinder performance, load distribution, and equipment stability. This information allows operators to make informed decisions, take corrective actions if necessary, and ensure ongoing safe operation.

Overall, telescopic cylinders contribute to stable and safe equipment operation through load distribution, weight management, controlled movements, shock absorption, operator safety, and monitoring capabilities. Their role in maintaining equipment stability and providing precise control enhances operational safety and reduces the risk of accidents or equipment failure.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders to ensure safe equipment usage.

Can telescopic cylinders be used for both lifting and pushing applications?

Yes, telescopic cylinders can be used for both lifting and pushing applications. Here’s a detailed explanation:

Lifting applications:

Telescopic cylinders are commonly employed in lifting applications where they provide the necessary force and stroke length to lift heavy loads. The nested structure of telescopic cylinders allows for extended stroke lengths while maintaining a compact retracted length. The hydraulic system supplies pressurized fluid to each stage, generating the force required for lifting. As the stages extend, the load is raised to the desired height.

Pushing applications:

In addition to lifting, telescopic cylinders can also be used for pushing applications. In these cases, the telescopic cylinder applies force in the opposite direction, typically to move or push objects or components. The hydraulic system supplies pressurized fluid to each stage, causing the stages to extend and exert a pushing force. The nested structure of the cylinder ensures that the force is transmitted through each stage, allowing for effective pushing.

Benefits of telescopic cylinders for lifting and pushing:

Telescopic cylinders offer several benefits for both lifting and pushing applications:

- Extended stroke length: Telescopic cylinders provide a longer stroke length compared to other types of cylinders, allowing for increased reach and movement in lifting and pushing operations.

- Compact retracted length: Despite their extended stroke length, telescopic cylinders have a compact retracted length. This is advantageous when space is limited or when a shorter cylinder length is desired.

- High force capabilities: Telescopic cylinders are designed to handle heavy loads and can generate significant force, making them suitable for lifting and pushing applications that require substantial power.

- Adjustability and flexibility: The hydraulic control system of telescopic cylinders allows for adjustability in terms of force, speed, and stroke length, providing flexibility and adaptability to different lifting and pushing requirements.

- Versatility: Telescopic cylinders can be used in various industries and applications, including construction, material handling, automotive, and more, making them versatile solutions for lifting and pushing tasks.

It’s important to consider the specific requirements of the lifting or pushing application and consult the manufacturer’s guidelines to ensure the proper selection, installation, and operation of telescopic cylinders in order to achieve safe and efficient performance.

editor by CX 2024-02-11

China manufacturer Factory Single Acting Hydraulic Cylinder for Dock Leveler a/c vacuum pump

Product Description

Factory Single Acting Hydraulic Cylinder for Dock Leveler

1. Cylinder Tube

(1)Material: Standard using ASTM 1571(steel 20), ASTM 1035(steel 35), ASTM 1040(steel 40) with Ra0.4 after honing and rolling.

(2)Tube choosing: standard is cold drawn seamless steel tube, if need hot rolling seamless steel tube, please inform us before quotation.

(3)Advice: Low pressure can use steel 20, high pressure can use steel 45. If customers have other special material request, can talk with us before quotation.

2. Piston Rod

(1) Material: Standard using ASTM 1035(steel 35) and ASTM 1045(steel 45).

(2) Piston Rod choosing: CHINAMFG piston rod and hollow piston rod (one of hollow piston rod end needs an air vent for welding and heating)

(3). Process: Quenching and tempering to reach hardness 229-285HB after roughing machining, if necessary, we also can reach hardness 45-55HRC after high frequency quenching. Standard chrome plated thickness is 25μm(if need more thickness, please inform us before quotation).

3. Piston

(1) Material: Standard material is wear-resisting cast iron, gray iron(HT300, HT350), steel and aluminum alloy, forging group II.

(2) The concentricity tolerance between piston and piston rod is 0.03mm.

4. Cylinder Cover

(1) Material: Cast iron for low pressure, gray iron HT300 for middle-low pressure. ASTM 1035(steel 35), ASTM 1045(steel 45) for middle-high pressure.

(2) Cylinder Cover choosing: It is better to use cast iron when cylinder cover also same function as guide sleeve, and melt brass, bronze or other wear-resisting material on the guide surface. If using the construct of pressing guide sleeve into cylinder cover, then the guide sleeve material should use wear-resisting cast iron, brass or bronze.

5. Seals

(1)Seals choosing: Good seal performance, low friction coefficient and small installation space of O-ring type Seals for low pressure, standard use our domestic brand. Middle-high pressure seals, we will use Y type, U type or V combined seals.

(2) Material:

| Material | NBR | HNBR | PU | FKM/FPM | FFPM | FFPM(Special) | PTEF |

| Limited Temp. | -30ºC~110ºC | -30ºC~135ºC | -30ºC~120ºC | -20ºC~200ºC | -20ºC~240ºC | -20ºC~320ºC | -55ºC~260ºC |

. FAQ .

Q1: Do you accept OEM manufacturing?

A1: Yes! We do accept OEM manufacturing. We will quote you the exact price and make the exact cylinder according to your specification and drawing.

Q2: Can we design our own package or print our own logo?

A2: Yes! Package and logo will be made acording to your requirements.

Q3: Could we get small quantity samples?

A3: Yes! We understand the quality test is important and we are glad to make the sample for you. The MOQ is 1pcs.

Q4: How long is the production time?

A4: Generally the production time is 25days.

Q5: What is the warranty?

A5: 1year against B/L date.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, CE, ISO9001 |

|---|---|

| Pressure: | Low Pressure |

| Work Temperature: | Low Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Switching Type |

| Samples: |

US$ 99/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do manufacturers ensure the durability and reliability of hydraulic cylinders?

Manufacturers employ various strategies and techniques to ensure the durability and reliability of hydraulic cylinders. These measures are crucial as hydraulic cylinders are often subjected to demanding operating conditions and heavy loads. To ensure their longevity and dependable performance, manufacturers focus on the following aspects:

1. High-Quality Materials:

– Manufacturers use high-quality materials in the construction of hydraulic cylinders. Components such as cylinder barrels, piston rods, seals, and bearings are made from materials that possess excellent strength, corrosion resistance, and wear resistance properties. Common materials used include high-grade steel alloys, chrome-plated rods, and specialized coatings. The selection of appropriate materials ensures that hydraulic cylinders can withstand the stresses, pressures, and environmental conditions they encounter during operation.

2. Robust Design:

– Hydraulic cylinders are designed to withstand high loads and harsh operating conditions. Manufacturers use computer-aided design (CAD) software and finite element analysis (FEA) techniques to optimize the cylinder’s structural integrity and performance. The design includes factors such as proper wall thickness, reinforcement in critical areas, and appropriate sizing of components. Robust design practices ensure that hydraulic cylinders can withstand the forces and stresses they encounter, preventing premature failure and ensuring durability.

3. Quality Manufacturing Processes:

– Manufacturers follow stringent quality control measures during the manufacturing processes of hydraulic cylinders. These processes include precision machining, welding, heat treatment, and surface finishing. Skilled technicians and advanced machinery are employed to ensure dimensional accuracy, proper fitment of components, and overall quality. By adhering to strict manufacturing processes and quality standards, manufacturers can produce hydraulic cylinders with consistent performance and reliability.

4. Sealing Technology:

– The sealing system of hydraulic cylinders is critical for their durability and reliability. Manufacturers utilize advanced sealing technologies such as lip seals, O-rings, and composite seals to prevent fluid leakage and ingress of contaminants. Properly designed and high-quality seals ensure that hydraulic cylinders can maintain their performance over extended periods. Seals are tested for their compatibility with the hydraulic fluid, pressure resistance, and resilience to environmental factors such as temperature and humidity.

5. Performance Testing:

– Manufacturers subject hydraulic cylinders to rigorous performance testing to validate their durability and reliability. These tests simulate real-world operating conditions and evaluate factors such as load capacity, pressure resistance, fatigue life, and leakage. Performance testing helps identify any design flaws or weaknesses in the hydraulic cylinder and allows manufacturers to make necessary improvements. By conducting thorough performance testing, manufacturers can ensure that hydraulic cylinders meet or exceed the required performance standards.

6. Compliance with Industry Standards:

– Manufacturers adhere to industry standards and regulations to ensure the durability and reliability of hydraulic cylinders. These standards, such as ISO 6020/6022 and NFPA T3.6.7, provide guidelines for design, manufacturing, and performance requirements. By following these standards, manufacturers ensure that hydraulic cylinders are designed and built to meet specific quality and safety criteria. Compliance with industry standards helps establish a baseline for durability and reliability and instills confidence in the performance of hydraulic cylinders.

7. Regular Maintenance and Service:

– Manufacturers provide recommendations for regular maintenance and service of hydraulic cylinders. This includes guidelines for lubrication, inspection of components, and replacement of wear parts such as seals and bearings. Following the manufacturer’s maintenance guidelines helps ensure the long-term durability and reliability of hydraulic cylinders. Regular maintenance also allows for the early detection of potential issues, preventing major failures and extending the service life of the hydraulic cylinders.

8. Customer Support and Warranty:

– Manufacturers provide customer support and warranty services to address any issues that arise with hydraulic cylinders. They offer technical assistance, troubleshooting guidance, and replacement of defective components. The warranty ensures that customers receive reliable and durable hydraulic cylinders and provides recourse in case of any manufacturing defects or premature failures. Strong customer support and warranty policies reflect the manufacturer’s commitment to the durability and reliability of their products.

In summary, manufacturers ensure the durability and reliability of hydraulic cylinders through the use of high-quality materials, robust design practices, stringent manufacturing processes, advanced sealing technology, thorough performance testing, compliance with industry standards, regular maintenance guidelines, and customer support with warranty services. By focusing on these aspects, manufacturers can produce hydraulic cylinders that can withstand demanding conditions, provide long service life, and deliver reliable performance in various applications.

What considerations are important when selecting hydraulic cylinders for mobile equipment?

To select hydraulic cylinders for mobile equipment, several important considerations need to be taken into account. Here are the key factors to consider:

- Load Capacity: Determine the maximum load or force that the hydraulic cylinder will need to support. This includes both the static load and any dynamic or shock loads that may be encountered during operation.

- Stroke Length: Consider the required stroke length, which is the distance the hydraulic cylinder can extend and retract. Ensure that the stroke length is sufficient for the specific application and range of motion needed.

- Operating Pressure: Determine the maximum operating pressure required for the hydraulic system. This will depend on the load and the specific application. Select a hydraulic cylinder with a pressure rating that exceeds the maximum operating pressure to ensure safety and durability.

- Mounting Style: Consider the available space and the mounting requirements of the mobile equipment. Hydraulic cylinders come in various mounting styles, such as flange, trunnion, clevis, and pivot, among others. Choose a mounting style that is compatible with the equipment and provides the necessary support and stability.

- Size and Weight: Take into account the physical dimensions and weight of the hydraulic cylinder. Ensure that it can fit within the available space and that the equipment can support its weight without compromising performance or safety.

- Speed and Precision: Evaluate the required speed and precision of the hydraulic cylinder’s movement. Different cylinder designs and configurations can affect the speed and accuracy of motion. Consider factors such as cylinder bore size, rod diameter, and the presence of cushioning or dampening features.

- Environmental Factors: Assess the operating environment of the mobile equipment. Consider factors such as temperature extremes, exposure to moisture, dust, and chemicals. Select hydraulic cylinders with appropriate seals and coatings that can withstand the environmental conditions and prevent corrosion or damage.

- Reliability and Maintenance: Consider the reliability and maintenance requirements of the hydraulic cylinders. Look for reputable manufacturers that provide high-quality products with a proven track record. Evaluate factors such as expected service life, availability of spare parts, and ease of maintenance.

- Cost: Finally, consider the cost of the hydraulic cylinders, including the initial purchase price, installation costs, and long-term maintenance expenses. While it is essential to find a cost-effective solution, prioritize quality and performance to ensure safe and efficient operation.

How do manufacturers ensure the quality and compatibility of hydraulic cylinders?

Manufacturers employ various measures to ensure the quality and compatibility of hydraulic cylinders, ensuring that they meet industry standards, performance requirements, and the specific needs of their customers. Here’s a detailed explanation of the methods and practices used by manufacturers to ensure the quality and compatibility of hydraulic cylinders:

1. Design and Engineering:

– Manufacturers employ skilled engineers and designers who have expertise in hydraulic systems and cylinder design. They use advanced design software and tools to create hydraulic cylinders that meet the desired specifications and performance requirements. Through careful analysis and simulation, manufacturers can ensure that the cylinders are designed to function optimally and provide the necessary force, stroke length, and reliability.

2. Material Selection:

– High-quality materials are crucial for the durability, performance, and compatibility of hydraulic cylinders. Manufacturers carefully select materials such as steel or other alloys based on their strength, corrosion resistance, and suitability for hydraulic applications. They source materials from reputable suppliers and perform quality checks to ensure that the materials meet the required standards and specifications.

3. Quality Control:

– Manufacturers implement robust quality control processes throughout the production of hydraulic cylinders. This includes rigorous inspections and tests at various stages of manufacturing, from raw material inspection to final assembly. Quality control personnel perform dimensional checks, surface finish inspections, and functional tests to verify that the cylinders meet the specified tolerances, performance criteria, and compatibility requirements.

4. Testing and Validation:

– Hydraulic cylinders undergo testing and validation procedures to ensure their performance, reliability, and compatibility. Manufacturers conduct various tests, such as pressure testing, leakage testing, load testing, and endurance testing. These tests simulate real-world operating conditions and verify that the cylinders can withstand the expected loads, pressures, and environmental factors. Additionally, manufacturers may perform compatibility testing to ensure that the cylinders can integrate seamlessly with other hydraulic system components.

5. Compliance with Standards:

– Manufacturers adhere to industry standards and regulations to ensure the quality and compatibility of hydraulic cylinders. They follow standards such as ISO 9001 for quality management systems and ISO 6020/2 or ISO 6022 for hydraulic cylinders. Compliance with these standards ensures that the manufacturing processes, quality control measures, and product performance meet internationally recognized benchmarks.

6. Certification and Accreditation:

– Manufacturers may obtain certifications and accreditations from recognized organizations to demonstrate their commitment to quality and compatibility. Certifications such as ISO certifications or third-party certifications provide assurance to customers that the hydraulic cylinders have undergone rigorous evaluations and meet specific quality and compatibility standards.

7. Customer Collaboration:

– Manufacturers actively engage with customers to understand their specific requirements and ensure compatibility. They work closely with customers to gather application-specific details, such as operating conditions, load requirements, and environmental factors. This collaborative approach allows manufacturers to customize hydraulic cylinders and provide solutions that are perfectly matched to the customer’s needs, ensuring compatibility and optimal performance.

8. Continuous Improvement:

– Manufacturers are committed to continuous improvement in their processes and products. They invest in research and development to incorporate the latest technologies, materials, and manufacturing techniques. By staying updated with industry advancements, manufacturers can enhance the quality, performance, and compatibility of their hydraulic cylinders over time.

By implementing effective design and engineering practices, selecting high-quality materials, conducting rigorous quality control, testing and validation procedures, complying with industry standards, obtaining certifications, collaborating with customers, and embracing continuous improvement, manufacturers ensure the quality and compatibility of hydraulic cylinders. These measures help to deliver reliable, high-performance cylinders that meet the diverse needs of industries and applications.

editor by CX 2024-02-08

China Standard CZPT Type Replacement S63DC-47-120 Single Acting Telescopic Dump Truck Hydraulic Cylinder with Good quality

Product Description

CHINAMFG type SAT S63DC-47-120 Replacement Dump Hoist Cylinder

General information

CHINAMFG Type Telescopic Hydraulic Cylinders are widely used in North America and South America.

Our company enjoys a reputation for quality custom built cylinders that demonstrate engineering know how and adept manufacturing.

| Bore diameter | Up to 20″ |

| Stroke | Up to 500″ |

| Operating pressures | Up to 10000psi |

| Materials & Coatings | Stainless steel Electroless nickel Nitriding Chrome Double chrome |

Using range

CHINAMFG type mobile cylinder is recognized as the brand of hydraulic cylinders for mobile equipment and leading products to refuse, mining, truck, material handling, and positioning markets. Parker’s Mobile Cylinder Division products include double and single acting telescopic cylinders, rod cylinders, and “smart cylinders” with internal electronic controls.

Specification

| Categories | Single-Acting Telescopic Cylinders |

| Function | Dump Hoist / Body Raise / Tipping |

| Weight | 315 lbs |

| Base End Mount Type | Cross tube |

| Rod End Mount Type | Pin -eye drilled thru lug |

| Closed | 52.62″ |

| Tele Largest Stage OD | 6″ |

| Telescopic Number of Stages | 3 |

| Telescopic Stroke | 120″ |

Hydraulic cylinders are the most effective and efficient method of pushing, pulling, lifting, and lowering.

Nowadays hydraulic cylinders play an essential role in daily application and industry:

√ Mining

√ Earthmoving & Construction

√ Agriculture &Forestry

√Waste Management & Material Handing

√Ship crane & offshore

Selecting the right cylinders for an application is critical in obtaining maximum performance and reliability.

CHINAMFG team considers all your concerns to suit your hydraulic cylinder requirements.

Together, we work out the best design solution for your application.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get the delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer’s samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our factory. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 1334.22/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do telescopic cylinders contribute to energy-efficient equipment operation?

Telescopic cylinders play a significant role in promoting energy-efficient equipment operation. Here’s a detailed explanation:

Reduced energy consumption:

Telescopic cylinders are designed to minimize energy consumption during equipment operation. The hydraulic system of telescopic cylinders allows for precise control over the extension and retraction of the cylinder stages. This control enables the equipment to use the minimum amount of hydraulic fluid and energy required to achieve the desired movement or position.

Efficient force transmission:

Telescopic cylinders are engineered to efficiently transmit forces from the hydraulic system to the desired application. The telescopic design allows for a direct and linear transfer of force, reducing energy losses that can occur in more complex mechanical systems. This efficient force transmission ensures that the energy supplied to the telescopic cylinder is effectively utilized to perform the desired work.

Compactness and weight reduction:

Telescopic cylinders offer compactness in equipment design, which contributes to energy efficiency. By retracting the cylinder stages, the overall length of the equipment can be minimized, reducing weight and inertia. This reduction in weight and inertia requires less energy to start and stop the movement of the equipment, resulting in energy savings during operation.

Optimized design:

Telescopic cylinders are designed with efficiency in mind. Manufacturers consider factors such as the cylinder’s bore size, rod diameter, and overall construction to ensure optimal performance while minimizing energy requirements. By using lightweight and high-strength materials, optimizing the cylinder’s dimensions, and reducing internal friction, telescopic cylinders can operate efficiently and contribute to energy savings.

Controlled motion:

Telescopic cylinders provide precise and controlled motion, allowing equipment operators to perform tasks with accuracy and efficiency. The hydraulic control system in telescopic cylinders enables smooth and proportional extension and retraction, reducing the need for excessive force or multiple adjustments. This controlled motion prevents energy waste and ensures that the equipment operates efficiently.

Applications in energy-efficient equipment:

Telescopic cylinders are utilized in various energy-efficient equipment, such as hybrid or electric-powered machinery. These equipment types rely on the optimization of energy usage to minimize environmental impact and reduce operating costs. Telescopic cylinders contribute to these objectives by providing efficient force transmission, controlled motion, and compact design.

Furthermore, the integration of advanced technologies, such as electronic control systems, sensors, and feedback mechanisms, can enhance the energy efficiency of equipment that incorporates telescopic cylinders. These technologies allow for further optimization of hydraulic system performance, energy recovery, and intelligent control of equipment operations.

Overall, telescopic cylinders contribute to energy-efficient equipment operation through reduced energy consumption, efficient force transmission, compactness and weight reduction, optimized design, and controlled motion. By utilizing telescopic cylinders in equipment design and considering energy-efficient practices, industries can achieve more sustainable and economical operation.

Consulting with equipment manufacturers or industry experts can provide further insights into the energy-saving benefits and applications of telescopic cylinders in specific equipment types.

How do telescopic cylinders handle variations in cylinder size and capacity?

Telescopic cylinders are designed to handle variations in cylinder size and capacity effectively. Here’s a detailed explanation:

Modular design:

Telescopic cylinders feature a modular design that allows for flexibility in cylinder size and capacity. They consist of multiple stages or sections that retract inside one another, similar to a telescope. The number of stages can vary depending on the desired extended length and capacity of the cylinder. This modular design enables telescopic cylinders to be customized according to specific requirements.

Variable stroke length:

Telescopic cylinders offer the advantage of variable stroke length. The stroke length refers to the distance the cylinder can extend and retract. By adjusting the stroke length, the effective size and capacity of the telescopic cylinder can be modified. This flexibility allows for accommodating variations in the size and capacity requirements of different applications.

Increased capacity with additional stages:

Telescopic cylinders can handle variations in capacity by adding more stages to the cylinder. Each stage contributes to the overall capacity of the cylinder. By including additional stages, the cylinder’s capacity can be increased to handle higher loads or operate in more demanding conditions. This scalability makes telescopic cylinders suitable for a wide range of applications with varying capacity needs.

Proportional force distribution:

Telescopic cylinders distribute the applied force proportionally across the stages. As the cylinder extends, each stage contributes to supporting the load and transmitting the force. The force distribution ensures that the load is evenly distributed among the stages, allowing the cylinder to handle variations in capacity effectively.

Hydraulic control system:

Telescopic cylinders rely on a hydraulic control system for operation. The system allows for precise control over the extension and retraction of each stage. By adjusting the hydraulic pressure and flow, operators can regulate the movement and force exerted by the cylinder, ensuring optimal performance and capacity utilization.

Overall, telescopic cylinders handle variations in cylinder size and capacity through their modular design, variable stroke length, ability to add stages for increased capacity, proportional force distribution, and hydraulic control system. These features make telescopic cylinders adaptable to different applications and enable them to effectively handle varying size and capacity requirements.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the size, capacity, and operational considerations of telescopic cylinders.

What industries commonly use telescopic cylinders in their applications?

Telescopic cylinders find applications in a wide range of industries where extended reach, height adjustment, or lifting capabilities are required. Here’s a detailed explanation:

Industries commonly using telescopic cylinders:

- Construction: The construction industry extensively utilizes telescopic cylinders in various equipment, including excavators, backhoes, loaders, cranes, and concrete pumps. Telescopic cylinders enable the extension and retraction of booms, arms, or buckets, providing the necessary reach, digging, and lifting capabilities in construction and earthmoving applications.

- Material Handling and Logistics: Telescopic cylinders are essential in industries involved in material handling and logistics operations. This includes applications such as cranes, forklifts, loaders, conveyor systems, and automated storage and retrieval systems. Telescopic cylinders enable the lifting, tilting, or extending movements required for efficient loading, unloading, and transportation of materials.

- Agriculture: The agricultural sector employs telescopic cylinders in various machinery, such as tractors, harvesters, sprayers, and irrigation systems. Telescopic cylinders facilitate height adjustment, folding/unfolding of implements, and movement of equipment parts, enhancing productivity and efficiency in agricultural operations.

- Transportation and Automotive: Telescopic cylinders play a role in the transportation and automotive industries. They are used in applications such as dump trucks, trailers, refuse trucks, car haulers, and hydraulic ramps. Telescopic cylinders enable the efficient tilting, dumping, or lifting of cargo, enhancing the functionality and versatility of transportation equipment.

- Marine and Offshore: The marine and offshore industries utilize telescopic cylinders in applications such as ship cranes, offshore platforms, and subsea equipment. Telescopic cylinders enable the extension and retraction of booms, arms, or lifting mechanisms, supporting various marine operations including cargo handling, offshore construction, and underwater exploration.

- Mining and Quarrying: In mining and quarrying operations, telescopic cylinders are employed in equipment such as excavators, loaders, and conveyor systems. They facilitate the necessary extension and retraction movements for digging, lifting, and conveying materials, enhancing productivity and efficiency in mining operations.

- Utilities and Energy: The utilities and energy sectors utilize telescopic cylinders in applications such as utility trucks, aerial platforms, power line maintenance equipment, and renewable energy installations. Telescopic cylinders enable the safe and efficient access to elevated work areas, equipment maintenance, and positioning of components in energy infrastructure.

- Manufacturing and Industrial: Telescopic cylinders are found in manufacturing and industrial environments in various machinery, including automated systems, assembly lines, robotic arms, and material handling equipment. They provide the necessary linear motion and reach for precise positioning, lifting, or transferring of components during manufacturing processes.

These are just a few examples of industries that commonly use telescopic cylinders in their applications. The versatility and efficiency of telescopic cylinders make them valuable components in numerous sectors where extended stroke lengths or compact retracted lengths are required.

It’s important to consult industry-specific guidelines and regulations to ensure the proper selection, installation, and maintenance of telescopic cylinders based on the specific application requirements.

editor by CX 2024-02-05

China supplier Long Stroke Mini Small Double Single Acting Lifting Telescopic Excavator CZPT 415 Arm Boom Bucket Hydraulic Cylinder vacuum pump ac system

Product Description

Company Profile

ZheJiang Zhongye Electromechanical Technology Co., LTD. is located in HangZhou High-tech International Enterprise Port Building 19, Liandong U Valley, High-tech Zone, HangZhou , ZheJiang Province, China.with a total investment of over 300 million yuan. Specializing in hydraulic piston pump, hydraulic valve, hydraulic motor, hydraulic cylinder and other hydraulic components research and development and remanufacturing.

Our boss has been engaged in the hydraulic industry for 36 years, and has a profound cultural background and understanding of the hydraulic field. He has successively established HangZhou CHINAMFG Excavator Co., LTD., ZheJiang CHINAMFG Fluid Transmission Co., LTD. In order to expand the operation and increase the export trade business, he introduced 2 directors with foreign investment experience to set up ZheJiang Zhongye Electromechanical Technology Co., LTD.

At Chairman, zhongye Electromechanical has close cooperation and exchanges with the leading universities in the field of fluid transmission in China, such as HangZhou Institute of Technology, and ZHangZhoug University, and has jointly established the “Fluid Transmission and Control Industry-University-Research Center” with HangZhou Institute of Technology, transforming scientific research theories into practical results. Determined to make the core characteristic service, and to do well, bigger, stronger, promote the common progress of the industry, drive the development of China’s hydraulic industry, to the world’s leading fluid transmission and control system.

Our Advantages

- We have a factory that produce pumps of KPM K3V/K5V/K7V series, The quality can be up to the same quality as the CHINAMFG , but the price is far below them. It has good cost performance because our boss has been in the hydraulic industry for 36 years, he is specializing in this technical research and is seriously at quality. If you have a market there, it will be a great advantage.

- In addition, we can also providing a variety of hydraulic parts for import brands. Some are we buy from CHINAMFG & CHINAMFG etc (china construction manufacturers )when they want to update the machine, but they has order the pumps motors…and the products will cause waste before they can be used, and we will buy from them that is why we can supply .

- Packaging: Adopt a variety of packaging and multiple protection to ensure the integrity of products.

- Double plastic bags: the inner layer is rust and oil proof, and the outer layer is double protection to prevent rain from affecting the external packaging and then affecting the product

- High elastic foam paper: secure and provide close protection to the product

- Wooden case: prevent direct impact on products during transportation

- Logistics: The company is equipped with logistics department and freight drivers to ensure the safety and timely delivery of goods to the designated place/warehouse/port.

- Certificates: CE and EAC (Russian customs union )

- Our factory is closed to ZheJiang port & HangZhou port.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in anti-rust treatment/polybag/foam boards and wooden cartons. If you have legally registered patent,we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% advance payment, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDP, DDU.

Q4. How about your delivery time?

A: Generally, it will take 5 to 10 days after receiving your advance payment if there are stock, otherwise it will take 20-25days. The specific delivery time depends on the items and the quantity of your order.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery to ensure the quality of products.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from.

Installation Instructions

1. oil purity In order to ensure the service life of the hydraulic cylinder, the hydraulic system must be set up in the filter, effectively prevent pollution, the purity of the oil should meet the ISO4406 standards, the quality of the filter should also meet the corresponding ISO standards. The actual condition of the filter shall be performed according to the system classification standard, but not lower than the minimum 19/15 rating of ISO4406, that is, the 24/15715 (beta) rating of ISO4572.

2. Hydraulic cylinder When the hydraulic cylinder needs to be stored for a period of time, the following methods are recommended: The hydraulic cylinder should be stored in a dry, clean, non-corrosive gas indoor environment, pay attention to protect the hydraulic cylinder from internal and external corrosion damage. The hydraulic cylinder should be as vertical as possible, and the piston rod upward, so that the hydraulic cylinder in the possibility of condensation caused by corrosion, and permanent deformation of the seal resulting in the weight of the piston and piston rod to a minimum. Hold oil port guard until connecting wire. Long-term storage, should be in the hydraulic cylinder piston on both sides of the filling application, to prevent corrosion in the cylinder. If the hydraulic cylinder is placed outside for a period of time, the unpainted surface such as the end of the piston rod should be protected.

3. One side under the protective cover of the hydraulic cylinder oil port can only be selected on the connecting line to prevent sundry entry. The connecting line must be cleaned and connected in series. The hydraulic system must be equipped with oil filter and tested regularly. In the case of a large number of fibers, fast drying chemicals adhesion, high temperature and splashing of impurities, the hydraulic cylinder must be unprotected. The piston rod should be fully tightened with load and checked regularly to prevent the connection thread from loosening; Irregular check guide rod end seal bushing and piston rod rotation deviation. The hydraulic cylinder must ensure the attachment of the piston rod and the connecting rod end, when the piston rod out and back in a straight line, otherwise it will lead to excessive wear of the gland and the cylinder, thus shortening the service life of the hydraulic cylinder. Different considerations for hydraulic cylinder installation During installation, it is recommended to choose thrust keys or thrust structures to resist the shear stress of the connection bolts. Rod mounting and extension lengths can be customized, and the installation torque is the same as the rod torque.

Certifications

Other Products

| K3V63DTP-60E01 | K3V180DT-HN0P | K3V112DTP-9C79 |

| K3V63DTP-60E02 | K3V180DTH-HN1V | K5V80DTP-9N05 |

| K7V63DTP-0E13/0E23 | K3V63DT-9N2H | K5V80DTP-9C05 |

| K3V112DTP-GYT6K | K3V63DT-9POH | K3V63DT-9N1S/9N01 |

| K3V112DTP-G9TEL | K3V112DTP-9TCM | K3V63DT-9COS |

| K3V112DTP-G9TDL | K3V112DTP-9T8L | K3V63DT-9N01 |

| K3V112DTP-9T1L | K3V112DTP-0E11 | K3V112DT-9N3P |

| K3V112DTP-9TBR | K5V140DTP-0E01 | K3V112DT-9N2A |

| K3V112DTP-9TBS | K5V140DTP-9T1L | K3V140DT-9N04 |

| K5V140DTP-YT6K | K5V160DTH-9T06 | K3V180DT-9N56 |

| K5V140DTP-9TBR | K5V200DTH-9N1H | K3V180DTP-9N05 |

| K5V140DTP-9TBS | K3V140DT-9TCM | K3V180DTH-9N2B |

| K3V63DTP-9N2B | K3V140DT-9T1L | K3V180DT-9N69 |

| K3V112DT-9C12 | K3V63DT-HNOV | K3V180DT-9C69 |

| K3V63DT-9N2J | K3V63DT-9N4H | K3V180DTH-9N1S/9N4S |

| K3V112DT-9N64 | K5V160DTH-9N4A | K3V180DTP-9COG |

| K3V112DT-9N49 | K3V63DT-9N2H | K5V200DTH-9C0Z |

| K5V140DT-9N25 | K7V63DTP | K3V63DT-HNOV |

| K3V112DT-9N94 | K3V112DT-9NC9 | K3V112DT-9C02 |

| K3V112DT-1E42 | K3V112DT-9ND9 | K3V112DT-HN0V |

| K5V160DT-1E05 | K5V160DTH-9N3A | K3V112DT-HN0V |

| K5V200DTH-9N2Y | K5V200DTH-9N1H | K3V112DTP-9N1T |

| K5V200DTP-9N8X | K3V180DTH-HN1V | K3V180DT-HN0P |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How do telescopic cylinders handle variations in environmental conditions?

Telescopic cylinders are designed to handle variations in environmental conditions effectively. Here’s a detailed explanation:

Durable construction:

Telescopic cylinders are constructed with durable materials such as steel or high-strength alloys, which provide resistance to environmental elements. These materials are chosen for their ability to withstand harsh conditions, including temperature extremes, moisture, and exposure to chemicals or corrosive substances.

Sealing mechanisms:

Telescopic cylinders incorporate sealing mechanisms to protect the internal components from contaminants and maintain proper operation in different environments. The seals prevent the entry of dust, dirt, water, and other particles that could potentially damage the cylinder’s internal components or affect its performance. Seals also help retain the hydraulic fluid, ensuring optimal lubrication and preventing leakage.

Corrosion resistance:

Telescopic cylinders are often coated with protective finishes or treatments to enhance their corrosion resistance. These coatings, such as paint, powder coating, or specialized coatings like chrome plating, create a barrier between the cylinder’s surface and the surrounding environment, reducing the risk of corrosion. Corrosion-resistant materials and treatments are particularly crucial in outdoor or marine applications where exposure to moisture, saltwater, or chemicals is common.

Temperature considerations:

Telescopic cylinders are designed to handle variations in temperature. The materials used in their construction are selected to withstand both low and high temperature ranges. Additionally, the hydraulic fluid used in the cylinders is chosen based on its ability to maintain consistent performance across different temperature conditions. In extreme temperature environments, additional insulation or heating elements may be incorporated to ensure proper fluid viscosity and prevent freezing or overheating.

Environmental sealing:

In certain applications where telescopic cylinders are exposed to extreme environmental conditions, additional sealing measures may be implemented. Environmental seals are designed to provide extra protection against water, dust, or other contaminants that are prevalent in specific environments. These seals are typically more robust and durable to maintain the integrity of the cylinder in challenging conditions.

Regular maintenance:

To ensure optimal performance and longevity, regular maintenance is essential for telescopic cylinders. This includes inspecting and cleaning the cylinders, checking and replacing worn seals, monitoring fluid levels and quality, and addressing any signs of damage or wear. Maintenance intervals may vary depending on the operating conditions and manufacturer recommendations.

Overall, telescopic cylinders are engineered to handle variations in environmental conditions by incorporating durable construction, sealing mechanisms, corrosion resistance, temperature considerations, environmental sealing, and regular maintenance. These features contribute to the reliability, longevity, and performance of telescopic cylinders in diverse industrial applications.

Consulting with manufacturers or industry experts can provide further guidance on selecting telescopic cylinders that are suitable for specific environmental conditions.

How do telescopic cylinders contribute to precise reach and manipulation?

Telescopic cylinders play a crucial role in enabling precise reach and manipulation in various applications. Here’s a detailed explanation:

Extended reach:

Telescopic cylinders allow for extended reach in equipment such as cranes, excavators, booms, and material handling machinery. The nested design of telescopic cylinders, with multiple stages that retract inside one another, enables the equipment to achieve a longer reach when required. By extending the telescopic cylinder, operators can access objects or work areas that are located at a distance.

Precise positioning:

Telescopic cylinders provide precise positioning capabilities, allowing operators to manipulate objects with accuracy. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, enabling smooth and controlled movement. This precise control is essential in applications that require accurate placement or manipulation of objects, such as in construction, manufacturing, or material handling.

Load handling:

Telescopic cylinders contribute to precise load handling by providing the necessary force and control. The cylinders are designed to handle heavy loads and can exert the required power to lift, lower, or manipulate objects with precision. The hydraulic control system allows operators to adjust the speed and movement of the telescopic cylinder, ensuring safe and controlled load handling.

Adaptability:

Telescopic cylinders offer adaptability in reaching and manipulating objects in various environments. Their nested design allows for compact retraction, making them suitable for applications with limited space. The ability to extend and retract the telescopic cylinder provides flexibility in adjusting the reach and adapting to different working conditions.

Support for attachments:

Telescopic cylinders often support attachments or tools that enhance reach and manipulation capabilities. For example, in excavators, telescopic cylinders are used to extend the boom or arm, while additional attachments such as buckets or grabs facilitate precise material handling or excavation tasks.

Overall, telescopic cylinders contribute to precise reach and manipulation by offering extended reach, precise positioning, load handling capabilities, adaptability, and support for attachments. Their hydraulic control system and nested design enable operators to achieve accurate and controlled movements, enhancing productivity and efficiency in various applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, operating parameters, and recommended maintenance practices to ensure optimal performance and safety.

What industries commonly use telescopic cylinders in their applications?

Telescopic cylinders find applications in a wide range of industries where extended reach, height adjustment, or lifting capabilities are required. Here’s a detailed explanation:

Industries commonly using telescopic cylinders:

- Construction: The construction industry extensively utilizes telescopic cylinders in various equipment, including excavators, backhoes, loaders, cranes, and concrete pumps. Telescopic cylinders enable the extension and retraction of booms, arms, or buckets, providing the necessary reach, digging, and lifting capabilities in construction and earthmoving applications.

- Material Handling and Logistics: Telescopic cylinders are essential in industries involved in material handling and logistics operations. This includes applications such as cranes, forklifts, loaders, conveyor systems, and automated storage and retrieval systems. Telescopic cylinders enable the lifting, tilting, or extending movements required for efficient loading, unloading, and transportation of materials.

- Agriculture: The agricultural sector employs telescopic cylinders in various machinery, such as tractors, harvesters, sprayers, and irrigation systems. Telescopic cylinders facilitate height adjustment, folding/unfolding of implements, and movement of equipment parts, enhancing productivity and efficiency in agricultural operations.

- Transportation and Automotive: Telescopic cylinders play a role in the transportation and automotive industries. They are used in applications such as dump trucks, trailers, refuse trucks, car haulers, and hydraulic ramps. Telescopic cylinders enable the efficient tilting, dumping, or lifting of cargo, enhancing the functionality and versatility of transportation equipment.

- Marine and Offshore: The marine and offshore industries utilize telescopic cylinders in applications such as ship cranes, offshore platforms, and subsea equipment. Telescopic cylinders enable the extension and retraction of booms, arms, or lifting mechanisms, supporting various marine operations including cargo handling, offshore construction, and underwater exploration.

- Mining and Quarrying: In mining and quarrying operations, telescopic cylinders are employed in equipment such as excavators, loaders, and conveyor systems. They facilitate the necessary extension and retraction movements for digging, lifting, and conveying materials, enhancing productivity and efficiency in mining operations.

- Utilities and Energy: The utilities and energy sectors utilize telescopic cylinders in applications such as utility trucks, aerial platforms, power line maintenance equipment, and renewable energy installations. Telescopic cylinders enable the safe and efficient access to elevated work areas, equipment maintenance, and positioning of components in energy infrastructure.

- Manufacturing and Industrial: Telescopic cylinders are found in manufacturing and industrial environments in various machinery, including automated systems, assembly lines, robotic arms, and material handling equipment. They provide the necessary linear motion and reach for precise positioning, lifting, or transferring of components during manufacturing processes.

These are just a few examples of industries that commonly use telescopic cylinders in their applications. The versatility and efficiency of telescopic cylinders make them valuable components in numerous sectors where extended stroke lengths or compact retracted lengths are required.

It’s important to consult industry-specific guidelines and regulations to ensure the proper selection, installation, and maintenance of telescopic cylinders based on the specific application requirements.

editor by CX 2024-02-04

China factory Durable Low-Maintenance Single Double Hydraulic Cylinder for Side Loader Garbage Truck wholesaler

Product Description

Hydraulic Cylinder used on Front Loader

Hydraulic cylinders are an integral part of many machines and devices, and front loaders are no exception. Front loaders, also known as front end loaders or simply loaders, are heavy equipment machines used for moving, handling, and lifting materials such as dirt, sand, rocks, and other construction debris. The hydraulic cylinder in a front loader is a key component that enables the machine to perform its various functions. It is responsible for lifting the bucket and moving it into position to scoop up material. The hydraulic cylinder also allows the bucket to be lowered and dumped, releasing the material at the desired location. The combination of the hydraulic cylinder and the front loader is a force to be reckoned with. They work together seamlessly, enabling the loader to perform tasks quickly and efficiently. The hydraulic cylinder’s strength and precision make it an indispensable part of the front loader, ensuring its smooth operation and reliability.

Hydraulic Cylinder used on Side Loader

The side loader garbage truck is a remarkable piece of engineering, designed with efficiency and hygiene in mind. The truck’s unique design, which includes a hydraulic cylinder, allows it to handle large volumes of trash with ease. The hydraulic cylinder in a side loader is made up of 2 main parts: the cylinder tube and the piston. The cylinder tube is a hollow metal cylinder that contains the hydraulic fluid. The piston is a CHINAMFG metal rod that slides within the cylinder tube. The hydraulic cylinder is the driving force behind the side loader garbage truck’s capabilities. It powers the lifting and tilting mechanisms that are essential for emptying trash containers into the truck’s body. The cylinder uses pressurized hydraulic fluid to generate the force necessary to manipulate the trash container.

Hydraulic Cylinder used on Rear Loader

The rear loader garbage truck is a specialized vehicle designed to handle the collection and disposal of trash in an efficient and hygienic manner. It features a unique loading mechanism that allows trash to be emptied directly into the truck’s body from the side, rather than from the rear or top.The hydraulic cylinder is what powers the trash container lifting mechanism. It uses pressurized hydraulic fluid to generate the force needed to tilt and empty the trash container into the truck’s hopper. This design allows for quick and effortless emptying, reducing the time and effort needed for trash collection.The hydraulic cylinder in a rear loader must be able to withstand significant forces and pressures, as it is responsible for lifting heavy loads and repeatedly performing this task over time.

About Us

Established in 1988 , HangZhou LD Machinery Co, LTD. (hereinafter referred to “LD”) is a leading manufacturer specializing in the design, research, development, manufacture and marketing in the hydraulic industry. Being one of major suppliers of customized components and cylinders for manufacturers spreaded all over the world, the company is committed to offer high quality products with competitive prices and excellent service worldwide.

Headquartered in HangZhou City, ZHangZhoug Province, the company wholly owns a subsidiary production factory named “HangZhou YUEWEI Hydraulic Technology Co., Ltd”, which covers an area of more than 380,000 square meters , possesses abundant technical strength and sound production management system, superior machining production equipment, strict and effective quality control system, advanced and excellent inspection instruments.

More than 35 years experience in machining industry, with over 10 experienced technical engineers and 150 skilled workers, LD has a senior engineering technical team with special skills and rich experience in product design, casting, forging, and CNC machining, can handle special material, structure, defect and processing, meet the evolving needs, and provide optimal solution and real one-stop service to customers.

Hydraulic Cylinder Producing Process

Step1: Quality Control on Raw Material

We have our own lab in factory, inspect the raw material and do the test. For every batch of material we received, we will ask supplier provide their certificate, and then cut them to do the test again to see if the results match the certification. Also, every batch we received, we will cut them into pieces to check the air bubbles. Once they are all qualified, we will accept it, and all detail information will be recording in our ERP system. We will also pay lot of attention on the salt spray test for chrome rod. Every month, we will cut the material, put them into test machine to see if it reach the requirement. All the result will be recorded at our QC department. If customer need, we can provide it.

Step2: Quality Control on Machining

we start doing components machining from 1988 with 36 years experience now and insist doing 100% inspection. We spend lots of money, invest on auto robots and machines. Now half of the producing line is by robot so that we can ensure our quality be stable good. For every part of the cylinder, we do 3 times inspecting. Firstly, workers will do self inspection. Secondly, we have tour-hour inspection checking the products, 2 times in the morning and 2 times in the afternoon, make sure that every step is good. After the products are all completed, we will do 100% inspection. For thread, for the tolerance, everything, we need double check. Also, we have specific warehouse just for the measuring tools. Every inspector have their own measuring tool and we will check the measuring tools regularly to make sure they are all in good condition, so that the measuring results will be convincing.

Step3: Quality Control on Welding

We are qualified to AWS certification, which is very popular in North American market. First, for the visual test, we will make sure that every components are welded good, look beautiful. And the second, we need to check the penetration. We have more than 15 years experience, we do know what kind of designing angle can make the cylinder welding strong. Once we finish the first article, we will cut it and analyse the welding to see if it is fulfill the groove. And then do the radiographic testing to make sure there is no gap inside. What’s more, we will do the ultrasonic test to check the program for the robot. Now 80% of welding is doing by robot. Once the program confirmed, no 1 can change it unless the welding manager, and they only have 5% right.

Step4: Quality Control on Assembling

For assembling, we have some difference with others. The brand we uses for seals are all those famous brand like Aston, Parker, Hallite. The cylinder we give to our customer has 2 years warranty. For our company, we engrave our part number and manufacturing date for the quality warranty. So no matter for seals or any others, as long as they are parts of cylinder, if it is under 2 years, we will take responsibility for them. And we will do the test for every cylinder like for pressure after we finish assembling.

Step5: Quality Control on Painting

We have our half auto painting line. Right now, we can paint about 1500 cylinders per day, which is about 1 container. Before we do the painting, we will do the wash first and for every cylinder, we will test for hardness, thickness and adhesion to make sure the painting are all good, which will be recorded into OQC report, print out and stick on the box, ship to you with your products.

Step6: Hydraulic Cylinder Packing

For every cylinder, we have the stick to show the detail information like bore size, stroke and working pressure. And we will use individual plastic bag packing. If customer need, we can also use individual carton box packing. We will fasten 1 floor after 1 floor with plat, so customer can only cut what they need and other layer will still be fasten. Moreover, there will be plywood pallet or plywood box for customer choosing. We will also send the loading picture to customer after we ship them to make sure everything is well loaded in China.

Packing Reference

Order Process

Enterprise Features

FAQ

Q1. What is LD product’s quality assurance?

100% inspection for each product before shipping with inspection rereport for tracking.

Q2: How long is the warranty on LD products?

The warranty is 2 years for general products since the date of shipment.

Q3: How LD deal with the quality problem during warranty period?

1. LD will take the corresponding cost caused by customer local reparing.

2. LD will provide the product by free if the repair cost is higher than the product value, but the freight involved shall be borne by customer side.

Q4: How to ensure the order can be shipped on time?

LD will send the “production schedule” every week after receiving customers’ orders. If any delays, LD will inform customers 3 weeks in advance, so as to facilitate the customer to arrange the schedule.

Q5: Does LD offer delivery service?

Yes. LD has deep cooperation with logistics companies all over the world to provide customers with quick and convenient “Door-to-Door services”,including sea, air and express.

Q6: How LD control the product quality?

1. Raw materials: We will test the material of each batch of raw materials we receive, and the piston rod will be tested with salt spray. This is to ensure that the material of our products meets the requirements at the beginning.

2. Processing: We have the leading machining equipment, and obtained ISO9001 certification.

3. Welding: Our factory is equipped with welding robots, and has obtained the AWS certification.

4. Assembly pressure test: 100% testing with OQC report for cHangZhou. The seals we use are: Hallite, Aston and Gapi

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 299/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What advancements in hydraulic cylinder technology have improved energy efficiency?

Advancements in hydraulic cylinder technology have led to significant improvements in energy efficiency, allowing hydraulic systems to operate more efficiently and reduce energy consumption. These advancements aim to minimize energy losses, optimize system performance, and enhance overall efficiency. Here’s a detailed explanation of some key advancements in hydraulic cylinder technology that have improved energy efficiency:

1. Efficient Hydraulic Circuit Design:

– The design of hydraulic circuits has evolved to improve energy efficiency. Advancements in circuit design techniques, such as load-sensing, pressure-compensated systems, or variable displacement pumps, help match the hydraulic power output to the actual load requirements. These designs reduce unnecessary energy consumption by adjusting the flow and pressure levels according to the system demands, rather than operating at a fixed high pressure.

2. High-Efficiency Hydraulic Fluids:

– The development of high-efficiency hydraulic fluids, such as low-viscosity or synthetic fluids, has contributed to improved energy efficiency. These fluids offer lower internal friction and reduced resistance to flow, resulting in decreased energy losses within the system. Additionally, advanced fluid additives and formulations enhance lubrication properties, reducing friction and optimizing the overall efficiency of hydraulic cylinders.

3. Advanced Sealing Technologies:

– Seal technology has advanced significantly, leading to improved energy efficiency in hydraulic cylinders. High-performance seals, such as low-friction or low-leakage seals, minimize internal leakage and friction losses. Reduced internal leakage helps maintain system pressure more effectively, resulting in less energy waste. Additionally, innovative sealing materials and designs enhance durability and extend seal life, reducing the need for frequent maintenance and replacement.

4. Electro-Hydraulic Control Systems:

– The integration of advanced electro-hydraulic control systems has greatly contributed to energy efficiency improvements. By combining electronic control with hydraulic power, these systems enable precise control over cylinder operation, optimizing energy usage. Proportional or servo valves, along with position or force feedback sensors, allow for accurate and responsive control, ensuring that hydraulic cylinders operate at the required level of performance while minimizing energy waste.

5. Energy Recovery Systems:

– Energy recovery systems, such as hydraulic accumulators, have been increasingly utilized to improve energy efficiency in hydraulic cylinder applications. Accumulators store excess energy during low-demand periods and release it when there is a peak demand, reducing the need for the hydraulic pump to provide the full power continuously. By utilizing stored energy, these systems can significantly reduce energy consumption and improve overall system efficiency.

6. Smart Monitoring and Control:

– Advancements in smart monitoring and control technologies have enabled real-time monitoring of hydraulic systems, allowing for optimized energy usage. Integrated sensors, data analytics, and control algorithms provide insights into system performance and energy consumption, enabling operators to make informed decisions and adjustments. By identifying inefficiencies or suboptimal operating conditions, energy consumption can be minimized, leading to improved energy efficiency.

7. System Integration and Optimization:

– The integration and optimization of hydraulic systems as a whole have played a significant role in improving energy efficiency. By considering the entire system layout, component sizing, and interaction between different elements, engineers can design hydraulic systems that operate in the most energy-efficient manner. Proper sizing of components, minimizing pressure drops, and reducing unnecessary piping or valve restrictions all contribute to improved energy efficiency of hydraulic cylinders.

8. Research and Development:

– Ongoing research and development efforts in the field of hydraulic cylinder technology continue to drive energy efficiency advancements. Innovations in materials, component design, system modeling, and simulation techniques help identify areas for improvement and optimize energy usage. Additionally, collaboration between industry stakeholders, research institutions, and regulatory bodies fosters the development of energy-efficient hydraulic cylinder technologies.

In summary, advancements in hydraulic cylinder technology have resulted in notable improvements in energy efficiency. Efficient hydraulic circuit designs, high-efficiency hydraulic fluids, advanced sealing technologies, electro-hydraulic control systems, energy recovery systems, smart monitoring and control, system integration and optimization, as well as ongoing research and development efforts, all contribute to reducing energy consumption and enhancing the overall energy efficiency of hydraulic cylinders. These advancements not only benefit the environment but also offer cost savings and improved performance in various hydraulic applications.

Customization of Hydraulic Cylinders for Marine and Offshore Applications

Yes, hydraulic cylinders can be customized for use in marine and offshore applications. These environments present unique challenges, such as exposure to corrosive saltwater, high humidity, and extreme operating conditions. Customization allows hydraulic cylinders to meet the specific requirements and withstand the harsh conditions encountered in marine and offshore settings. Let’s delve into the details of how hydraulic cylinders can be customized for marine and offshore applications:

- Corrosion Resistance: Marine and offshore environments expose hydraulic cylinders to corrosive elements, such as saltwater. To mitigate corrosion, hydraulic cylinders can be customized with materials and surface treatments that provide enhanced corrosion resistance. For example, cylinders can be constructed from stainless steel or coated with protective layers like chrome plating or specialized coatings to withstand the corrosive effects of saltwater.