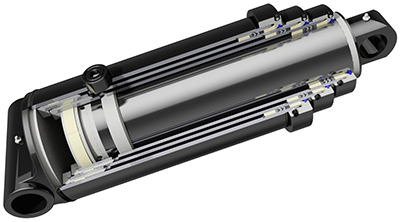

Product Description

HangZhou CHINAMFG CUSTOMIZED CYLINDER

Introduction

ROCA is a Chinese-based manufacturer of engineered hydraulic cylinders. Our manufacturing facilities are certified to the ISO 9001 standard. We are also an approved supplier to many large OEM equipment manufacturers in the mobile industry. Most of our customers are from North America and Europe. We offer high quality products at very affordable pricing. We take pride in our flexible delivery programs and offer a competitive warranty, be assured, we stand by our product.

Advantage

√ Optional raw material, we can provide no matter normal material or special material, especially St52.3.

√ High quality seals, such as Hallite.

√ CNC machines, assure definition in all processes.

√ Chrome and nitrided rod

√ 150 hours salt spray test

√ German testing tools and equipment.

Customized cylinder application worksheet

Company information

Quote Quantity:_______________ Company name:_____________________ Contact Name:________________

Type 1

Type 2

Type 3

Product information

Cylinder application _____________________ Single or Double-Acting ______________________ Fluid Type __________

O.D. largest moving sleeve ____________ System operating pressure _____________ Number of moving sleeves __________

System flow in G.P.M. ____________ Chrome or non-chrome sleeves _________ System operating temp ________________

Any side or eccentric loading ______________ Load holding requirements _______________

Mounting conditions Vert. __ Horz. __ Incline angle ____

A. Total stroke ________ B. Retracted length ________ C. Extended length ________ D. Base mount radius ___________

E. Base mount pin Dia. _____________ F. Plunger mount radius ____________ G. Plunger mount pin Dia. _____________

H. Plunger mount length _____________ I. Base mount length __________________ J. Packing nut to pin ____________

K. O.D. of main barrel _______________ F. Plunger mount radius ________________

Extend port size & type ________________ Extend port location ________________

Retract port size & type ________________ Retract port location ________________

Special features or comments __________________________________________________________________________

Hydraulic cylinders are the most effective and efficient method of pushing, pulling, lifting, and lowering.

Nowadays hydraulic cylinders play an essential role in daily application and industry:

√ Mining

√ Earthmoving & Construction

√ Agriculture &Forestry

√Waste Management & Material Handing

√Ship crane & offshore

Selecting the right cylinders for an application is critical in obtaining maximum performance and reliability.

CHINAMFG team takes all your concerns into consideration to suit your hydraulic cylinder requirements.

Together, we work out the best design solution for your application.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get the delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap 1 in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer’s samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | Low to High Pressure |

| Work Temperature: | Low to High Temp |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do telescopic cylinders contribute to efficient and controlled extension and retraction?

Telescopic cylinders play a crucial role in enabling efficient and controlled extension and retraction. Here’s a detailed explanation:

Nested design:

The nested design of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for efficient extension and retraction. Each stage extends or retracts in a synchronized manner, contributing to smooth and controlled movement. The nested structure also enables compact storage when the cylinder is retracted, optimizing space utilization.

Hydraulic control system:

The hydraulic control system is a key component that enables efficient and controlled extension and retraction of telescopic cylinders. It utilizes hydraulic fluid and pressure to drive the cylinder’s movement. By regulating the flow of hydraulic fluid to each stage, the extension and retraction speed can be precisely controlled. This hydraulic control system ensures synchronized movement of the stages and allows for gradual and controlled extension and retraction.

Valve and cylinder design:

Telescopic cylinders incorporate specific valve and cylinder designs to facilitate efficient and controlled extension and retraction. Flow control valves, such as flow restrictors or throttle valves, are often used to regulate the flow rate of hydraulic fluid to each stage. These valves help manage the speed of extension and retraction, preventing sudden or uncontrolled movements. The cylinder design, including the bore size and rod diameter, is carefully engineered to optimize the balance between extension/retraction speed and force output.

Pressure relief and damping:

To further enhance controlled extension and retraction, telescopic cylinders may incorporate pressure relief and damping mechanisms. Pressure relief valves help prevent over-pressurization of the hydraulic system, ensuring that the cylinder operates within safe limits. Damping devices, such as hydraulic cushions or shock absorbers, can be integrated to dampen the impact or vibrations during extension and retraction, promoting smoother and more controlled movement.

Load-specific adjustments:

Telescopic cylinders can be adjusted to accommodate different load requirements, contributing to efficient and controlled extension and retraction. By adding or removing stages or adjusting the hydraulic pressure, operators can adapt the cylinder’s performance to match the specific load conditions. This customization ensures optimal extension and retraction characteristics for different applications and load capacities.

Overall, the nested design, hydraulic control system, valve and cylinder design, pressure relief mechanisms, and load-specific adjustments all work together to enable telescopic cylinders to contribute to efficient and controlled extension and retraction. These features ensure smooth operation, precise positioning, and safe handling of heavy loads in various industrial applications.

Consulting the manufacturer’s documentation and guidelines is important for understanding the specific capabilities and limitations of telescopic cylinders in terms of extension and retraction.

How do telescopic cylinders contribute to precise reach and manipulation?

Telescopic cylinders play a crucial role in enabling precise reach and manipulation in various applications. Here’s a detailed explanation:

Extended reach:

Telescopic cylinders allow for extended reach in equipment such as cranes, excavators, booms, and material handling machinery. The nested design of telescopic cylinders, with multiple stages that retract inside one another, enables the equipment to achieve a longer reach when required. By extending the telescopic cylinder, operators can access objects or work areas that are located at a distance.

Precise positioning:

Telescopic cylinders provide precise positioning capabilities, allowing operators to manipulate objects with accuracy. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, enabling smooth and controlled movement. This precise control is essential in applications that require accurate placement or manipulation of objects, such as in construction, manufacturing, or material handling.

Load handling:

Telescopic cylinders contribute to precise load handling by providing the necessary force and control. The cylinders are designed to handle heavy loads and can exert the required power to lift, lower, or manipulate objects with precision. The hydraulic control system allows operators to adjust the speed and movement of the telescopic cylinder, ensuring safe and controlled load handling.

Adaptability:

Telescopic cylinders offer adaptability in reaching and manipulating objects in various environments. Their nested design allows for compact retraction, making them suitable for applications with limited space. The ability to extend and retract the telescopic cylinder provides flexibility in adjusting the reach and adapting to different working conditions.

Support for attachments:

Telescopic cylinders often support attachments or tools that enhance reach and manipulation capabilities. For example, in excavators, telescopic cylinders are used to extend the boom or arm, while additional attachments such as buckets or grabs facilitate precise material handling or excavation tasks.

Overall, telescopic cylinders contribute to precise reach and manipulation by offering extended reach, precise positioning, load handling capabilities, adaptability, and support for attachments. Their hydraulic control system and nested design enable operators to achieve accurate and controlled movements, enhancing productivity and efficiency in various applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, operating parameters, and recommended maintenance practices to ensure optimal performance and safety.

Can telescopic cylinders be used for both lifting and pushing applications?

Yes, telescopic cylinders can be used for both lifting and pushing applications. Here’s a detailed explanation:

Lifting applications:

Telescopic cylinders are commonly employed in lifting applications where they provide the necessary force and stroke length to lift heavy loads. The nested structure of telescopic cylinders allows for extended stroke lengths while maintaining a compact retracted length. The hydraulic system supplies pressurized fluid to each stage, generating the force required for lifting. As the stages extend, the load is raised to the desired height.

Pushing applications:

In addition to lifting, telescopic cylinders can also be used for pushing applications. In these cases, the telescopic cylinder applies force in the opposite direction, typically to move or push objects or components. The hydraulic system supplies pressurized fluid to each stage, causing the stages to extend and exert a pushing force. The nested structure of the cylinder ensures that the force is transmitted through each stage, allowing for effective pushing.

Benefits of telescopic cylinders for lifting and pushing:

Telescopic cylinders offer several benefits for both lifting and pushing applications:

- Extended stroke length: Telescopic cylinders provide a longer stroke length compared to other types of cylinders, allowing for increased reach and movement in lifting and pushing operations.

- Compact retracted length: Despite their extended stroke length, telescopic cylinders have a compact retracted length. This is advantageous when space is limited or when a shorter cylinder length is desired.

- High force capabilities: Telescopic cylinders are designed to handle heavy loads and can generate significant force, making them suitable for lifting and pushing applications that require substantial power.

- Adjustability and flexibility: The hydraulic control system of telescopic cylinders allows for adjustability in terms of force, speed, and stroke length, providing flexibility and adaptability to different lifting and pushing requirements.

- Versatility: Telescopic cylinders can be used in various industries and applications, including construction, material handling, automotive, and more, making them versatile solutions for lifting and pushing tasks.

It’s important to consider the specific requirements of the lifting or pushing application and consult the manufacturer’s guidelines to ensure the proper selection, installation, and operation of telescopic cylinders in order to achieve safe and efficient performance.

editor by Dream 2024-05-16