Product Description

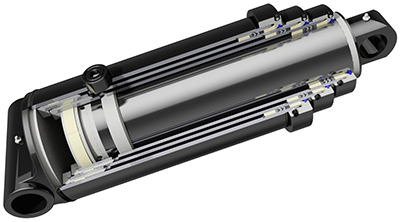

Dump Truck Trailer Single Acting Telescopic Good Quality Hydraulic Cylinder

Product Description

THE NORTH AMERICAN TYPE FRONT-END TELESCOPIC CYLINDERS

Thin-wall cylinders

1.The North American advanced processing technology is adopted to ensure the stable performance.

2.High quality alloy seamless steel pipe are adopted to keep big lifting capacity and light weight;

3.The application of imperial size makes it easy to replace the seals and other accessories;

4.Superior chrome-plating technology improves the corrosion resistance and hardness of cylinders;

5.The world famous brands of seals such as HALLITE, CHINAMFG and NOK ensure the sealing performance;

|

Front end telescopic cylinder scope |

||||

|

Bore size |

90mm-220mm |

|||

|

Stage |

2-6 stages |

|||

|

Stroke |

Maximum 12000mm(450″) |

|||

|

Working pressure |

Maximum 210bar(3000PSI) |

|||

|

Mounting style |

CC, DC, DB |

|||

|

Painting |

Follow customers’ requirement |

|||

|

Materials and technology |

||||

|

Barrel/Tube |

1. Material: SAE1571(20#) , SAE1045(45#) ,16Mn(Q345B),27SiMn,etc. 2. Technology: cold drawn ,hot rolled,forged 3. Surface Roughness: R0.16-0.32μm 4. Choose by different working condition and requirements.

|

|||

|

Piston rod |

1. Material: SAE1045(45#),35CrMo,42CrMo4,etc. 3. Surface treatment: chrome plated, nickel-chromium plated, nitriding, nitrocarburizing |

|||

|

Seal kits |

1. Hallite, NOK, Parker, Hercules,Trelleborg,China made,ZheJiang made 2. Choose by different working condition and requirements. |

|||

Company Profile

JUNRUI specialize in the production and R&D of Dump Truck&Trailer Telescopic Hydraulic Cylinder, Dump Truck Hydraulic System,Agricultural Machinery Hydraulic Cylinder, Garbage Truck Hydraulic Cylinder, Tipping Platform Hydraulic Cylinder,

Snow Plow Hydraulic Cylinder and so on.

Over the years development,our products have been exported to America, Australia, Russia, Canada, Mexico,Colombia,

Netherlands etc and have been widely praised by the customers from home and abroad.

We are committed to providing customers with high quality and reasonable price products.

All Junrui products are designed,engineered and manufactured by highly skilled and experienced engineers,

All the products do QC 3 times before delivery to make sure the quality.

We are committed to providing customers with high quality and reasonable price products. All Junrui products are designed,

engineered and manufactured by highly skilled and experienced engineers, All the products do QC 3 times before delivery to

make sure the quality. The company has imported CNC deep hole boring machines, CNC laser cutting machines, CNC machining

centers, CNC cleaning machines, automatic assembly lines for hydraulic cylinders, robot welding stations, automatic welding

machines and other precision processing equipment, over 200 sets. After years of development, JUNRUI Hydraulic has developed

into an enterprise with complete hardware facilities, sophisticated processing equipment, strong technical force, and good social

benefits. For the stable development of your main business, we look CHINAMFG to cooperating with you.

PRODUCTION PROCESS

Equipment

Packaging & Shipping

Certifications

Exhibition

Application

Q1: Are you a trading company or a manufacturer?

A: We have our own factory.

Q2: Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, 15-30 working days if we don’t. but it also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to contact us.

Q6: What are your After-sales services?

A: Before shipment, Each individual product will be strictly inspected on our factory QC Process System. In addition, We have a

Customer Service team to respond to customers’ questions within 12 hours. Being helpful in solving customers’ problems is always

our goal. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can telescopic cylinders be used in construction equipment like cranes?

Yes, telescopic cylinders are commonly used in construction equipment, including cranes. Here’s a detailed explanation:

Role in crane operation:

Telescopic cylinders play a critical role in the operation of cranes by enabling the extension and retraction of crane booms or arms. The telescopic cylinder is typically located at the base of the boom and is responsible for extending or retracting the boom sections, allowing the crane to reach different heights and distances.

Extension and retraction mechanism:

The telescopic cylinder in a crane consists of multiple stages or sleeves that retract inside one another. This nested design allows for compact storage when the boom is retracted, minimizing the overall length of the crane. When the cylinder extends, the stages slide out, increasing the length of the boom and providing the necessary reach. The synchronized extension and retraction of the stages are facilitated by the hydraulic control system.

Hydraulic control system:

The hydraulic control system in cranes is responsible for the precise and controlled extension and retraction of telescopic cylinders. It regulates the flow of hydraulic fluid to each stage of the cylinder, ensuring synchronized movement. By adjusting the flow rate, the operator can control the speed of extension and retraction, allowing for smooth and controlled operation of the crane.

Load handling capabilities:

Telescopic cylinders in cranes are designed to handle significant loads. They provide the necessary lifting force to support heavy loads at various boom lengths. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and to deliver the required lifting capacities.

Variety of crane types:

Telescopic cylinders are utilized in various types of cranes, including mobile cranes, truck-mounted cranes, and crawler cranes. These cranes are widely used in construction sites, infrastructure projects, and other lifting and material handling applications. The versatility of telescopic cylinders allows them to be integrated into different crane designs and configurations.

Advantages of telescopic cylinders in cranes:

Telescopic cylinders offer several advantages in crane applications. These include:

- Compactness: Telescopic cylinders enable the boom to be retracted to a compact size, making it easier to transport and maneuver the crane in confined spaces.

- Reach and height capabilities: The telescopic design allows the crane to achieve extended reach and height, enabling it to access elevated work areas or reach over obstacles.

- Efficiency: The controlled extension and retraction of telescopic cylinders contribute to efficient operation, allowing the crane to adjust its boom length quickly and precisely.

- Stability: Telescopic cylinders provide stability to the crane by supporting the boom and load, ensuring safe lifting and lowering of heavy objects.

Overall, telescopic cylinders are integral components of construction equipment like cranes. They enable the extension and retraction of crane booms, contribute to efficient and controlled operation, and enhance the lifting capabilities of cranes in various construction and material handling tasks.

It’s important to consult the crane manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

How do telescopic cylinders handle variations in hydraulic pressure and flow rate?

Telescopic cylinders are designed to handle variations in hydraulic pressure and flow rate effectively. Here’s a detailed explanation:

Hydraulic pressure control:

Telescopic cylinders are equipped with hydraulic systems that allow for precise control of hydraulic pressure. The hydraulic pressure is regulated by a pump that supplies pressurized hydraulic fluid to the cylinder. The pressure can be adjusted according to the specific requirements of the application.

Pressure relief valves:

To handle variations in hydraulic pressure, telescopic cylinders often incorporate pressure relief valves. These valves are designed to limit the maximum pressure within the cylinder to prevent damage or failure. When the pressure exceeds the set limit, the relief valve opens, allowing excess fluid to bypass and relieve the pressure. This ensures the safety and integrity of the telescopic cylinder and the hydraulic system.

Flow control:

Telescopic cylinders also handle variations in flow rate through the hydraulic control system. The flow rate of hydraulic fluid into and out of the cylinder determines the speed of extension and retraction. Flow control valves, such as flow restrictors or flow control valves, are commonly employed to regulate the flow rate.

Flow restrictors:

Flow restrictors are used to limit the flow rate of hydraulic fluid entering or leaving the telescopic cylinder. By restricting the flow, the speed of extension or retraction can be controlled. This allows for precise and gradual movement, preventing abrupt or uncontrolled motion.

Flow control valves:

Flow control valves are designed to provide adjustable flow rates by regulating the opening or closing of hydraulic passages. These valves allow operators to control the speed of extension and retraction of the telescopic cylinder. By adjusting the flow control valves, variations in flow rate can be accommodated to suit specific operational requirements.

Sequencing valves:

In some applications, telescopic cylinders may require a specific sequence of extension and retraction. Sequencing valves are used to control the order in which different stages of the telescopic cylinder extend or retract. These valves ensure proper synchronization of the cylinder stages and prevent uneven or unbalanced movement.

Overall, telescopic cylinders employ various hydraulic components and control mechanisms to handle variations in hydraulic pressure and flow rate. Pressure relief valves protect against excessive pressure, flow restrictors and flow control valves regulate the flow rate, and sequencing valves ensure proper sequencing of cylinder stages. These features allow telescopic cylinders to operate safely, precisely, and efficiently under different hydraulic conditions.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the hydraulic system and control mechanisms of telescopic cylinders, as well as recommended maintenance and safety practices.

Can you explain the purpose and role of telescopic cylinders in machinery?

Telescopic cylinders play a crucial role in various machinery and equipment applications. Here’s a detailed explanation:

Purpose of telescopic cylinders:

Telescopic cylinders are primarily used when an extended stroke length is required while maintaining a compact retracted length. They enable machinery and equipment to achieve extended reach, height adjustment, or lifting capabilities without increasing the overall size or footprint of the cylinder. The purpose of telescopic cylinders is to provide efficient and reliable linear motion in applications that demand long stroke lengths.

Role of telescopic cylinders in machinery:

- Material Handling: Telescopic cylinders are extensively used in material handling machinery, such as cranes, forklifts, and loaders. They enable the extension and retraction of booms, arms, or lifting mechanisms, allowing operators to reach higher or farther to handle and transport materials with ease.

- Dump Trucks and Trailers: Telescopic cylinders are commonly employed in dump trucks and trailers for the tilting and unloading of cargo or bulk materials. The extendable stroke of the cylinder raises the bed or container to dump the contents, enabling efficient unloading and reducing manual labor.

- Aerial Platforms: Telescopic cylinders are essential components in aerial work platforms, such as cherry pickers or scissor lifts. They facilitate the vertical movement and height adjustment of the platform, allowing operators to access elevated work areas safely.

- Construction Equipment: Telescopic cylinders are used in various construction equipment, including excavators, backhoes, and telescopic handlers. They provide the necessary extension and retraction for the boom, arm, or bucket, enabling digging, lifting, and reaching capabilities in construction and earthmoving applications.

- Mobile Equipment: Telescopic cylinders are utilized in mobile equipment, such as telescopic cranes and mobile cranes. They enable the extension and retraction of the boom sections, allowing for increased reach and lifting capacities in lifting and construction operations.

- Specialized Machinery: Telescopic cylinders find application in specialized machinery, such as fire truck aerial ladders, telescopic masts, or telescopic booms in industrial and military equipment. They provide the required extension and retraction for specific tasks, such as firefighting, surveillance, or equipment deployment.

The role of telescopic cylinders in machinery is to provide precise and controlled linear motion, enabling the equipment to perform specific tasks with extended reach, height adjustment, or lifting capabilities. They contribute to the efficiency, versatility, and productivity of machinery in various industries.

It’s important to ensure proper selection, installation, and maintenance of telescopic cylinders based on the specific machinery requirements and manufacturer’s guidelines to ensure safe and reliable operation.

editor by CX 2024-04-17

China Custom Dump Bed Kit Hydraulic Hoist Kit Hydraulic Cylinder with Hydraulic Power Unit for Trailer vacuum pump and compressor

Product Description

DESCRIPTION

Hydraulic scissor hoist kit for Tipper trailer/Dump truck

Hydraulic scissor hoist kit

Application: Tipper trailer, dump truck etc.

Load capacity: 1-10 tons

Complete kit including 1 set hoist frame, 1 pc hydraulic

cylinder, 1 set hydraulic power unit, 2 pcs hoses and connectors.

PS: We can also provide the Hinges, Safety Arm, Battery Cables, Rubber Battery Strap.

Hoist Mechanism,Dimensions & Mass(appros.)

| L(mm) | W(mm) | H(mm) | X(mm) | MASS(kg) |

| 1180 | 402 | 340 | 391 | 120 |

|

Model |

Recommended Gross Vehicle Mass |

Cabin Length |

Rear overhang length | Distance between load centre and hinge | Distance between trunnion and height | Rated lifting capacity | Design maximum lifting capacity and angle |

| KRM92-1 | 4000-5000 | 3100 | 340 | 1210 | 1270 | 2000-3000 | 60/5500 |

| KRM200-48 | 28000-35000 | 8000 | 1000 | 2000 | 3380 | 18000-25000 | 53/35000 |

| KRM143B | 6000-9000 | 3400 | 400 | 1300 | 1100 | 4000-5000 | 60/8500 |

| KRM160C | 11000-17000 | 4500 | 750 | 1500 | 2050 | 6000-8000 | 52/16000 |

| KRM160S | 8000-11000 | 3800 | 600 | 1300 | 1400 | 6000-8000 | 52/11000 |

| KRM220 | 20000-39000 | 8000 | 1200 | 3000 | 3630 | 20000-29000 | 47/39000 |

| KRM183 | 21000-29000 | 5300 | 900 | 1750 | 2480 | 15000-17000 | 53/27000 |

Hoist Cylinder and Pump Combination Specification (approx.)

|

Hoist Cylinder KRM143 |

Working Pressure (MPa) (Kgf/cm2) |

6.4 |

Gear Pump KP-55 |

Standard Revolution (rpm) |

800 |

| 65 | 55 | ||||

| Inner Diameter (mm) | 140 | Discharge Volume(ml/rev.) | 20.6 | ||

| Stroke (mm) | 520 |

Max. Testing Pressure (MPa) (Kgf/cm2) |

|||

| Min. Close distance (mm) | 795 | 210 | |||

| Piston Rod Diameter (mm) | 70 |

Weight(kg) |

13 | ||

| Max. pressure (MPa) (Kgf/cm2) |

14.7 | ||||

| 150 |

Hoist Mounting and Maximum Lifting Capacity

| Recommended Truck G.W.(kg) | Body Length(mm) | Rear Overhang(mm) | Distance between Load Center to Hinge(mm) | Distance between trunion to Hinge(mm) | Rated Lifting Capacity(kg) | Designed Max. lifting Capacity(kg) (including load weight) |

| 6000-9000 | 3400 | 400 | 1300 | 1100 | 4000-5000 | 8500/60° |

DETAILS

ADVANTAGES

APPLICATIONS

Company Profile

Packing & Shipping

FAQ

Q1:What’s the brand name of your products ?

A:Generally,we use our own brand “East-Ai”,OEM is also available as required.

Q2:Hydraulic cylinder internal leakage?

A: There are 3 main reasons causing internal leakage :Overload,polishing is not well

controlled,bad seal kits.As is known to all,vehicles in China are often overload,our products all designed to bear the overload power.We have numerical control machine to assure the polish processing .And we use the imported seals to meet customers’ demands.

Q3:Does your piston rod get ruptured easily?

A: Hard chrome plating quenched and tempered 45# steel for piston rod to assure sufficient hardness and toughness.

Q4:Is your design reasonable? What about your product safe coefficient?

A:We have R&D team with abundant design experience. We also established production, education, and research cooperation with universities . Rest assured.

Q5:What about the quality feedback of your products?

A: Guarantee the quality from the raw material. We have cold drawing production line and nickel-chrome electroplating production line , so we can produce cold-drawing pipe and hard-chrome pipe used for hydraulic cylinder. !!!

WE HAVE NEVER RECEIVED EVEN ONCE QUALITY COMPLAINT FOR MANY YEARS OF INTERNATIONAL TRADE.

Q6:Is the sample free?

A:Yes.In our acceptable range, we can offer a sample by charging freight. And we will return the fee after you place bulk order.

Q7:How about the delivery time?

A: Over 700 sets advanced equipments to meet customer’s large demand in short delivery time.Generally ,it’s 7-15 days.

Q8:What ‘s the after-service? A:If the quality can’t meet your requirement ,we will pay all your lost and offer technical support to solve your problem!!!

Q9:How can I contact with you ?

| Certification: | RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do hydraulic cylinders handle the challenges of minimizing friction and wear?

Hydraulic cylinders employ several mechanisms and techniques to effectively minimize friction and wear, ensuring optimal performance and longevity. Minimizing friction and wear is crucial for hydraulic cylinders as it helps to maintain efficiency, reduce energy consumption, and prevent premature failure. Here’s a detailed explanation of how hydraulic cylinders handle the challenges of minimizing friction and wear:

1. Lubrication:

– Proper lubrication is essential for minimizing friction and wear in hydraulic cylinders. Lubricating fluids, such as hydraulic oils, are used to create a thin film between moving surfaces, reducing direct metal-to-metal contact. This lubricating film acts as a protective barrier, reducing friction and preventing wear. Regular maintenance practices include monitoring and maintaining the appropriate lubricant levels to ensure optimal lubrication and minimize frictional losses.

2. Surface Finishes:

– The surface finishes of components in hydraulic cylinders play a crucial role in minimizing friction and wear. Smoother surface finishes, achieved through precision machining, grinding, or the application of specialized coatings, reduce surface roughness and frictional resistance. By minimizing surface irregularities, the risk of wear and friction-induced damage is significantly reduced, resulting in improved efficiency and extended component life.

3. High-Quality Sealing Systems:

– Well-designed and high-quality sealing systems are crucial for minimizing friction and wear in hydraulic cylinders. Seals prevent fluid leakage and contamination while maintaining proper lubrication. Advanced sealing materials, such as polyurethane or composite materials, offer excellent wear resistance and low friction characteristics. Optimal seal design and proper installation ensure effective sealing, minimizing friction and wear between the piston and cylinder bore.

4. Proper Alignment and Clearances:

– Hydraulic cylinders must be properly aligned and have appropriate clearances to minimize friction and wear. Misalignment or excessive clearances can result in increased friction and uneven wear, leading to premature failure. Proper installation, alignment, and maintenance practices, including regular inspection and adjustment of clearances, help ensure smooth and even movement of the piston within the cylinder, reducing friction and wear.

5. Filtration and Contamination Control:

– Effective filtration and contamination control are essential for minimizing friction and wear in hydraulic cylinders. Contaminants, such as particles or moisture, can act as abrasive agents, accelerating wear and increasing friction. By implementing robust filtration systems and proper maintenance practices, hydraulic systems can prevent the ingress of contaminants, ensuring clean and properly lubricated components. Clean hydraulic fluids help minimize wear and friction, contributing to improved performance and longevity.

6. Material Selection:

– The selection of appropriate materials for hydraulic cylinder components is crucial in minimizing friction and wear. Components subject to high frictional forces, such as pistons and cylinder bores, can be made from materials with excellent wear resistance, such as hardened steel or composite materials. Additionally, selecting materials with low coefficients of friction helps reduce frictional losses. Proper material selection ensures durability and minimized wear in critical components of hydraulic cylinders.

7. Maintenance and Regular Inspection:

– Regular maintenance and inspection practices are vital for identifying and addressing potential issues that could lead to increased friction and wear in hydraulic cylinders. Scheduled maintenance includes lubrication checks, seal inspections, and monitoring of clearances. By promptly detecting and rectifying any signs of wear or misalignment, hydraulic cylinders can be kept in optimal condition, minimizing friction and wear throughout their operational lifespan.

In summary, hydraulic cylinders employ various strategies to handle the challenges of minimizing friction and wear. These include proper lubrication, employing suitable surface finishes, utilizing high-quality sealing systems, ensuring proper alignment and clearances, implementing effective filtration and contamination control measures, selecting appropriate materials, and conducting regular maintenance and inspections. By implementing these practices, hydraulic cylinders can minimize friction and wear, ensuring smooth and efficient operation while extending the overall lifespan of the system.

Contribution of Hydraulic Cylinders to the Precision of Robotic and Automation Systems

Hydraulic cylinders play a significant role in enhancing the precision of robotic and automation systems. These systems rely on precise and controlled movements to perform various tasks with accuracy and repeatability. Let’s explore how hydraulic cylinders contribute to the precision of robotic and automation systems:

- Precise Positioning: Hydraulic cylinders enable precise positioning of robotic arms or automation components. They provide accurate control over the linear motion required for tasks such as picking, placing, and assembly. By precisely controlling the extension and retraction of the hydraulic cylinder, the system can achieve the desired position with high accuracy, ensuring precise alignment and consistent results.

- Controlled Motion: Hydraulic cylinders offer controlled and smooth motion, which is crucial for precise operation in robotic and automation systems. The flow of hydraulic fluid can be precisely regulated to control the speed and acceleration of the cylinder’s movement. This precise control allows for gentle and controlled movements, minimizing vibrations, overshooting, or jerky motions that could affect the accuracy of the system.

- Force Control: Hydraulic cylinders provide force control capabilities that contribute to precision in robotic and automation systems. By adjusting the hydraulic pressure, the force exerted by the cylinder can be precisely controlled. This is particularly valuable in applications that require delicate force-sensitive tasks, such as gripping fragile objects or performing precise force feedback during assembly or testing processes.

- Load Handling: Hydraulic cylinders are capable of handling heavy loads, allowing robotic and automation systems to manipulate and transport objects with precision. The high force capabilities of hydraulic cylinders ensure secure and stable handling of loads, minimizing the risk of slippage or imprecise positioning. This is crucial in applications where precise control over heavy objects is required, such as material handling or industrial assembly processes.

- Durability and Reliability: Hydraulic cylinders are known for their durability and reliability in demanding industrial environments. The ability to withstand repeated use, high loads, and harsh conditions ensures consistent performance over time. This reliability contributes to the precision of robotic and automation systems, as any deviation or failure in the cylinder’s movement could lead to inaccuracies or disruptions in the system’s operation.

In summary, hydraulic cylinders make significant contributions to the precision of robotic and automation systems by enabling precise positioning, controlled motion, force control, load handling, and offering durability and reliability. These capabilities ensure accurate and repeatable movements, minimize errors, and enhance the overall precision of the system. By incorporating hydraulic cylinders into robotic and automation systems, manufacturers can achieve higher levels of precision, efficiency, and productivity in various industrial applications.

How do hydraulic cylinders handle variations in load and pressure during operation?

Hydraulic cylinders are designed to handle variations in load and pressure during operation, making them versatile and efficient in various applications. Hydraulic systems use the principle of transmitting force through incompressible fluid to generate linear motion. Here’s a detailed explanation of how hydraulic cylinders handle variations in load and pressure:

1. Load Handling:

– Hydraulic cylinders are capable of handling different loads by utilizing the principle of Pascal’s law. According to Pascal’s law, when pressure is applied to a fluid in a confined space, the pressure is transmitted equally in all directions. In a hydraulic cylinder, the force applied to the piston results in an equal force output at the rod end of the cylinder. The size of the piston and the pressure exerted determine the force generated by the cylinder. Therefore, hydraulic cylinders can handle a wide range of loads by adjusting the pressure applied to the fluid.

2. Pressure Compensation:

– Hydraulic systems incorporate pressure compensation mechanisms to handle variations in pressure during operation. Pressure compensating valves or regulators are often used to maintain a consistent pressure in the hydraulic system, regardless of load changes. These valves automatically adjust the flow rate or pressure to ensure stable and controlled operation of the hydraulic cylinder. By compensating for pressure variations, hydraulic cylinders can maintain a consistent force output and prevent damage or instability due to excessive pressure.

3. Control Valves:

– Control valves play a crucial role in managing variations in pressure and load during hydraulic cylinder operation. Directional control valves, such as spool valves or poppet valves, control the flow of hydraulic fluid into and out of the cylinder, enabling precise control of the cylinder’s extension and retraction. By adjusting the position of the control valve, the speed and force exerted by the hydraulic cylinder can be regulated to match the load and pressure requirements of the application. Control valves allow for efficient handling of variations in load and pressure by providing fine-tuned control over the hydraulic system.

4. Accumulators:

– Hydraulic accumulators are often used to handle fluctuations in pressure and load. Accumulators store hydraulic fluid under pressure, which can be released or absorbed as needed to compensate for sudden changes in load or pressure. When the load on the hydraulic cylinder decreases, the accumulator releases stored fluid to maintain pressure and prevent pressure spikes. Conversely, when the load on the cylinder increases, the accumulator absorbs excess fluid to maintain system stability. By utilizing accumulators, hydraulic cylinders can effectively handle variations in load and pressure, ensuring smooth and controlled operation.

5. Feedback and Control Systems:

– Advanced hydraulic systems may incorporate feedback and control systems to monitor and adjust the operation of hydraulic cylinders in real-time. Position sensors or pressure sensors provide feedback on the cylinder’s position, force, and pressure, allowing the control system to make continuous adjustments to optimize performance. These systems can automatically adapt to variations in load and pressure, ensuring precise control and efficient operation of the hydraulic cylinder.

6. Design Considerations:

– Proper design considerations, such as selecting the appropriate cylinder size, piston diameter, and rod diameter, are essential for handling variations in load and pressure. The design should account for the maximum anticipated load and pressure conditions to ensure the hydraulic cylinder operates within its specified range. Additionally, the selection of suitable seals, materials, and components that can withstand the anticipated load and pressure variations is crucial for maintaining the reliability and longevity of the hydraulic cylinder.

By utilizing the principles of hydraulic systems, incorporating pressure compensation mechanisms, employing control valves and accumulators, and implementing feedback and control systems, hydraulic cylinders can effectively handle variations in load and pressure during operation. These features and design considerations allow hydraulic cylinders to adapt and perform optimally in a wide range of applications and operating conditions.

editor by CX 2023-11-22

China Custom Customized Hydraulic Power Oil Hydraulic Cylinder for truck mounted crane vacuum pump electric

Product Description

Customized Hydraulic Power Oil Hydraulic Cylinder for truck mounted crane

Part 1—–PRODUCT DETAILS

A.Product Description:

1. With Rolling technology, the cylinder is straighter, the surface is harder and its quality is more durable.

2. All piston rod have to go through comprehensive processing: Heat treating Lathing GrindingPolishingHard chrome plating Polishing, this comprehensive processing make the cylinder harder, wearable and acid-proof.

3. Using imported materials for seal kits.

4. The structure kits are made by high-strength Manganese plate

5. Advanced surface treatment:

A. Environmental automatically pipelined painting

B. Cleaning with automatic washing machine

C. Assembling in seal clean workshop

B. Other information:

| Item | Specifications |

| Product Name: | China Factory Customized Truck mounted crane Hydraulic Cylinder |

| Certificate: | ISO16949 |

| Production Capacity: | 200,000 pcs per year |

| Sample Time: | 7-15 days |

| Brand | Xihu (West Lake) Dis.ng or customer’s logo |

| Service | OEM & ODM |

| Piston Rod | Chrome or nickel plated,ground & polished piston rod |

| Seal Type | as customer’s requirement |

| Tube | High tensile cold drawn tube, precision honed for extended seal life |

| Delivery Time | Based on order quantity. normally 15-30 days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer & Exporter |

Part 2——-Application:

Hydraulic Cylinder Product Application

Xihu (West Lake) Dis.ng’s quality custom products are produced for OEM applications in a wide variety of CHINAMFG industries, including manufacturing engineering machinery, loaders hydraulic cylinders, vehicle cylinders, construction, forestry, waste management, mining, material handling, industrial applications, agriculture, manufacturing, transportation, marine applications and oil field equipment. Our success has been built on the engineering expertise and manufacturing capabilities we offer to meet the very specific demands of our industry clients.

Part 3——-Why Choose Us

1. Product Research & Development:

Xihu (West Lake) Dis.ng builds quality products that are developed with use in mind. We specialize in working with every customer to share ideas and gather critical information regarding hydraulic cylinder fit and performance requirements for your specific application.

2.Hydraulic Cylinder Production:

We have the advanced CNC machine tools, a horizontal machining center, a welding robot, parts cleaning agent, automatic assembly lines, automatic painting equipment etc. to hydraulic cylinder ensure a 360-degree quality control of the production process.

3.Hydraulic Cylinder Product Certifications:

4.Perfect after-service:

5. Professional Hydraulic Cylinder Team:

Part 4——Company Information:

ZheJiang XIHU (WEST LAKE) DIS.NG TECHNOLOGY CO.,LTD is a famous hydraulic cylinder manufacture in HangZhou city,ZheJiang province of China. The Head office XIHU (WEST LAKE) DIS.NG was founed in 2001,the main products include a variety of special hydraulic cylinder.It has 5 subsidiaries, and ZheJiang Best Crane Co., Ltd. is 1 of them. The companies are interrelated and independently accounted for and operate independently. The company now covers an area of more than 400 acres, with total assets of 500 million yuan, more than 800 employees, more than 700 sets of high-precision equipment, total industrial output value of over 1 billion yuan, and annual taxes of more than 30 million yuan.

After 20 years development,XIHU (WEST LAKE) DIS.NG now covers an area of 200,000 Square meters, ownes a registered capital of 1000 million RMB,and 250 million RMB worth of fixed assets .XIHU (WEST LAKE) DIS.NG has established long time cooperation with over 80 big companies like Zoomlion, Fukuda Fortaleza, CHINAMFG Vehicle Group, and so on.

Our company have more than 800 units equipment for mass production.We can product around 220 thousand units per year of hydraulic cylinder and 500 units per year of truck crane.

Our company have more than 150 technical staff, Have more than 10 invention patents and 60 utility patents.So we can produce customized products or develop new products.

Good quality is our culture.Welcome to visit our company and build up a long friendship with us!

Part 5—–FAQ

1: What kind terms of payment can be accepted?

A: For terms of payment, L/C, T/T, D/A, D/P, Western Union (can be) could accepted

2: How to pack and transport?

A: Nude with safty protection, only crane can be packed into containers for shipment.

And the truck mounted crane can be deliveried with ro-ro ship.

3: How long is the delivery time??

A: 35 days after receiving the deposit.

4: What about the warranty time?

A: 12 months after shipment or 2000 working hours, whichever occuts first.

5. What about the Minimum Order Quantity?

A: 1 unit. For customized products, the MOQ can be Negotiated.

| Certification: | ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Low Temperature |

| Acting Way: | Single Acting |

| Working Method: | Rotary |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

How do manufacturers ensure the durability and reliability of hydraulic cylinders?

Manufacturers employ various strategies and techniques to ensure the durability and reliability of hydraulic cylinders. These measures are crucial as hydraulic cylinders are often subjected to demanding operating conditions and heavy loads. To ensure their longevity and dependable performance, manufacturers focus on the following aspects:

1. High-Quality Materials:

– Manufacturers use high-quality materials in the construction of hydraulic cylinders. Components such as cylinder barrels, piston rods, seals, and bearings are made from materials that possess excellent strength, corrosion resistance, and wear resistance properties. Common materials used include high-grade steel alloys, chrome-plated rods, and specialized coatings. The selection of appropriate materials ensures that hydraulic cylinders can withstand the stresses, pressures, and environmental conditions they encounter during operation.

2. Robust Design:

– Hydraulic cylinders are designed to withstand high loads and harsh operating conditions. Manufacturers use computer-aided design (CAD) software and finite element analysis (FEA) techniques to optimize the cylinder’s structural integrity and performance. The design includes factors such as proper wall thickness, reinforcement in critical areas, and appropriate sizing of components. Robust design practices ensure that hydraulic cylinders can withstand the forces and stresses they encounter, preventing premature failure and ensuring durability.

3. Quality Manufacturing Processes:

– Manufacturers follow stringent quality control measures during the manufacturing processes of hydraulic cylinders. These processes include precision machining, welding, heat treatment, and surface finishing. Skilled technicians and advanced machinery are employed to ensure dimensional accuracy, proper fitment of components, and overall quality. By adhering to strict manufacturing processes and quality standards, manufacturers can produce hydraulic cylinders with consistent performance and reliability.

4. Sealing Technology:

– The sealing system of hydraulic cylinders is critical for their durability and reliability. Manufacturers utilize advanced sealing technologies such as lip seals, O-rings, and composite seals to prevent fluid leakage and ingress of contaminants. Properly designed and high-quality seals ensure that hydraulic cylinders can maintain their performance over extended periods. Seals are tested for their compatibility with the hydraulic fluid, pressure resistance, and resilience to environmental factors such as temperature and humidity.

5. Performance Testing:

– Manufacturers subject hydraulic cylinders to rigorous performance testing to validate their durability and reliability. These tests simulate real-world operating conditions and evaluate factors such as load capacity, pressure resistance, fatigue life, and leakage. Performance testing helps identify any design flaws or weaknesses in the hydraulic cylinder and allows manufacturers to make necessary improvements. By conducting thorough performance testing, manufacturers can ensure that hydraulic cylinders meet or exceed the required performance standards.

6. Compliance with Industry Standards:

– Manufacturers adhere to industry standards and regulations to ensure the durability and reliability of hydraulic cylinders. These standards, such as ISO 6020/6022 and NFPA T3.6.7, provide guidelines for design, manufacturing, and performance requirements. By following these standards, manufacturers ensure that hydraulic cylinders are designed and built to meet specific quality and safety criteria. Compliance with industry standards helps establish a baseline for durability and reliability and instills confidence in the performance of hydraulic cylinders.

7. Regular Maintenance and Service:

– Manufacturers provide recommendations for regular maintenance and service of hydraulic cylinders. This includes guidelines for lubrication, inspection of components, and replacement of wear parts such as seals and bearings. Following the manufacturer’s maintenance guidelines helps ensure the long-term durability and reliability of hydraulic cylinders. Regular maintenance also allows for the early detection of potential issues, preventing major failures and extending the service life of the hydraulic cylinders.

8. Customer Support and Warranty:

– Manufacturers provide customer support and warranty services to address any issues that arise with hydraulic cylinders. They offer technical assistance, troubleshooting guidance, and replacement of defective components. The warranty ensures that customers receive reliable and durable hydraulic cylinders and provides recourse in case of any manufacturing defects or premature failures. Strong customer support and warranty policies reflect the manufacturer’s commitment to the durability and reliability of their products.

In summary, manufacturers ensure the durability and reliability of hydraulic cylinders through the use of high-quality materials, robust design practices, stringent manufacturing processes, advanced sealing technology, thorough performance testing, compliance with industry standards, regular maintenance guidelines, and customer support with warranty services. By focusing on these aspects, manufacturers can produce hydraulic cylinders that can withstand demanding conditions, provide long service life, and deliver reliable performance in various applications.

Adaptation of Hydraulic Cylinders for Medical Equipment and Aerospace Applications

Hydraulic cylinders have the potential to be adapted for use in medical equipment and aerospace applications, offering unique advantages in these industries. Let’s explore how hydraulic cylinders can be adapted for these specialized fields:

- Medical Equipment: Hydraulic cylinders can be adapted for various medical equipment applications, including hospital beds, patient lifts, surgical tables, and rehabilitation devices. Here’s how hydraulic cylinders are beneficial in medical equipment:

- Positioning and Adjustability: Hydraulic cylinders provide precise and smooth movement, allowing for accurate positioning and adjustments of medical equipment. This is crucial for ensuring patient comfort, proper alignment, and ease of use.

- Load Handling: Hydraulic cylinders offer high force capabilities, enabling the safe handling of heavy loads in medical equipment. They can support the weight of patients, facilitate smooth transitions, and provide stability during procedures.

- Controlled Motion: Hydraulic cylinders provide controlled and stable motion, which is essential for delicate medical procedures. The ability to adjust speed, position, and force allows for precise and controlled movements, minimizing patient discomfort and ensuring accurate treatment.

- Durability and Reliability: Hydraulic cylinders are designed to withstand rigorous use and demanding environments, making them suitable for medical equipment applications. Their durability and reliability contribute to the long-term performance and safety of medical devices.

- Aerospace Applications: Hydraulic cylinders can also be adapted for aerospace applications, where lightweight yet robust systems are essential. Here’s how hydraulic cylinders are advantageous in aerospace:

- Flight Control Systems: Hydraulic cylinders play a critical role in aircraft flight control systems, including ailerons, elevators, rudders, and landing gear. They provide precise and reliable actuation, allowing pilots to control the aircraft’s movements with accuracy and responsiveness.

- Weight Optimization: Hydraulic cylinders can be designed using lightweight materials, such as aluminum alloys or composite materials, to reduce overall weight. This weight optimization is crucial in aerospace applications to enhance fuel efficiency, payload capacity, and aircraft performance.

- Shock and Vibration Resistance: Aerospace environments involve significant shock and vibration forces. Hydraulic cylinders can be engineered to withstand these dynamic loads while maintaining performance and reliability, ensuring consistent operation even under extreme conditions.

- Space Constraints: Hydraulic cylinders can be designed to fit within the space constraints of aircraft or spacecraft. Their compact size and flexible mounting options allow for efficient integration into the limited available space.

In summary, hydraulic cylinders can be adapted for use in medical equipment and aerospace applications, leveraging their precise positioning, load handling capabilities, controlled motion, durability, and reliability. In medical equipment, hydraulic cylinders enable comfortable patient positioning, smooth transitions, and controlled movements during procedures. In aerospace, hydraulic cylinders provide precise actuation, weight optimization, shock and vibration resistance, and space-efficient solutions. By adapting hydraulic cylinders to these specialized fields, manufacturers can meet the unique requirements and enhance the performance of medical equipment and aerospace systems.

What factors should be considered when selecting the right hydraulic cylinder for an application?

When selecting the right hydraulic cylinder for an application, several important factors need to be considered. These factors help ensure that the chosen hydraulic cylinder is suitable for the specific requirements of the application and will perform reliably. Here are the key factors to consider:

1. Load Requirements:

– One of the crucial factors to consider is the load requirement of the application. Determine the maximum load that the hydraulic cylinder needs to handle. Consider both the static load (when the cylinder is stationary) and the dynamic load (when the cylinder is in motion). The load requirement will impact the cylinder’s bore size, rod diameter, and overall strength. Choose a hydraulic cylinder with a load capacity that exceeds the application’s maximum load to ensure safety and longevity.

2. Stroke Length:

– The stroke length refers to the distance the hydraulic cylinder needs to extend and retract to perform the desired motion. Measure the required stroke length based on the application’s operational requirements. It is essential to choose a hydraulic cylinder with a stroke length that matches or exceeds the required distance. Consider any potential variations or adjustments in the stroke length that may be needed in the future.

3. Operating Pressure:

– Consider the operating pressure required for the application. The hydraulic cylinder must be capable of withstanding the maximum pressure within the hydraulic system. Ensure that the selected cylinder has a pressure rating that exceeds the application’s maximum operating pressure. This ensures safety and prevents premature failure.

4. Speed Requirements:

– Determine the required speed of the hydraulic cylinder’s movement for the application. Consider both the extension and retraction speeds. Select a cylinder that can achieve the desired speed while maintaining precise control and stability. It is important to choose a cylinder that can handle the required speed without compromising performance or safety.

5. Mounting:

– Evaluate the available space and mounting requirements for the hydraulic cylinder. Consider the mounting type (such as flange, foot, trunnion, or clevis), the available mounting points, and any specific mounting constraints. Ensure that the selected cylinder can be easily and securely mounted in the desired location.

6. Environmental Factors:

– Assess the environmental conditions in which the hydraulic cylinder will operate. Consider factors such as temperature extremes, humidity, exposure to chemicals, dust, or corrosive substances. Choose a cylinder that is designed to withstand the specific environmental conditions of the application. This may involve selecting appropriate materials, coatings, or seals to ensure the longevity and performance of the cylinder.

7. Cylinder Configuration:

– Determine the appropriate cylinder configuration based on the application’s requirements. Consider factors such as single-acting or double-acting cylinders, telescopic cylinders for limited space, or custom configurations for unique applications. Evaluate the specific needs of the application to select the most suitable cylinder configuration.

8. Maintenance and Serviceability:

– Consider the maintenance and service requirements of the hydraulic cylinder. Evaluate factors such as ease of access for maintenance, availability of spare parts, and the reputation of the manufacturer or supplier in terms of customer support and after-sales service. Choosing a reliable and reputable brand can ensure ongoing support and availability of spare parts when needed.

9. Compliance and Standards:

– Depending on the industry and application, certain compliance standards may need to be met. Consider any industry-specific regulations, safety standards, or certifications that the hydraulic cylinder should comply with. Ensure that the selected cylinder meets the required standards and certifications for the application.

10. Cost and Budget:

– Finally, consider the cost and budget for the hydraulic cylinder. While it is important to select a cylinder that meets the application’s requirements, it is also necessary to consider the overall cost-effectiveness. Evaluate the initial purchase cost, long-term maintenance costs, and the expected lifespan of the cylinder. Balancing the cost and quality will help in selecting a hydraulic cylinder that provides the best value for the application.

By considering these factors in the selection process, it becomes possible to choose the right hydraulic cylinder that meets the specific requirements of the application in terms of load capacity, stroke length, operating pressure, speed, mounting, environmental conditions, maintenance needs, compliance, and cost-effectiveness. Proper selection ensures optimal performance, reliability, and longevity of the hydraulic cylinder in the intended application.

editor by CX 2023-11-17