Product Description

Product Description

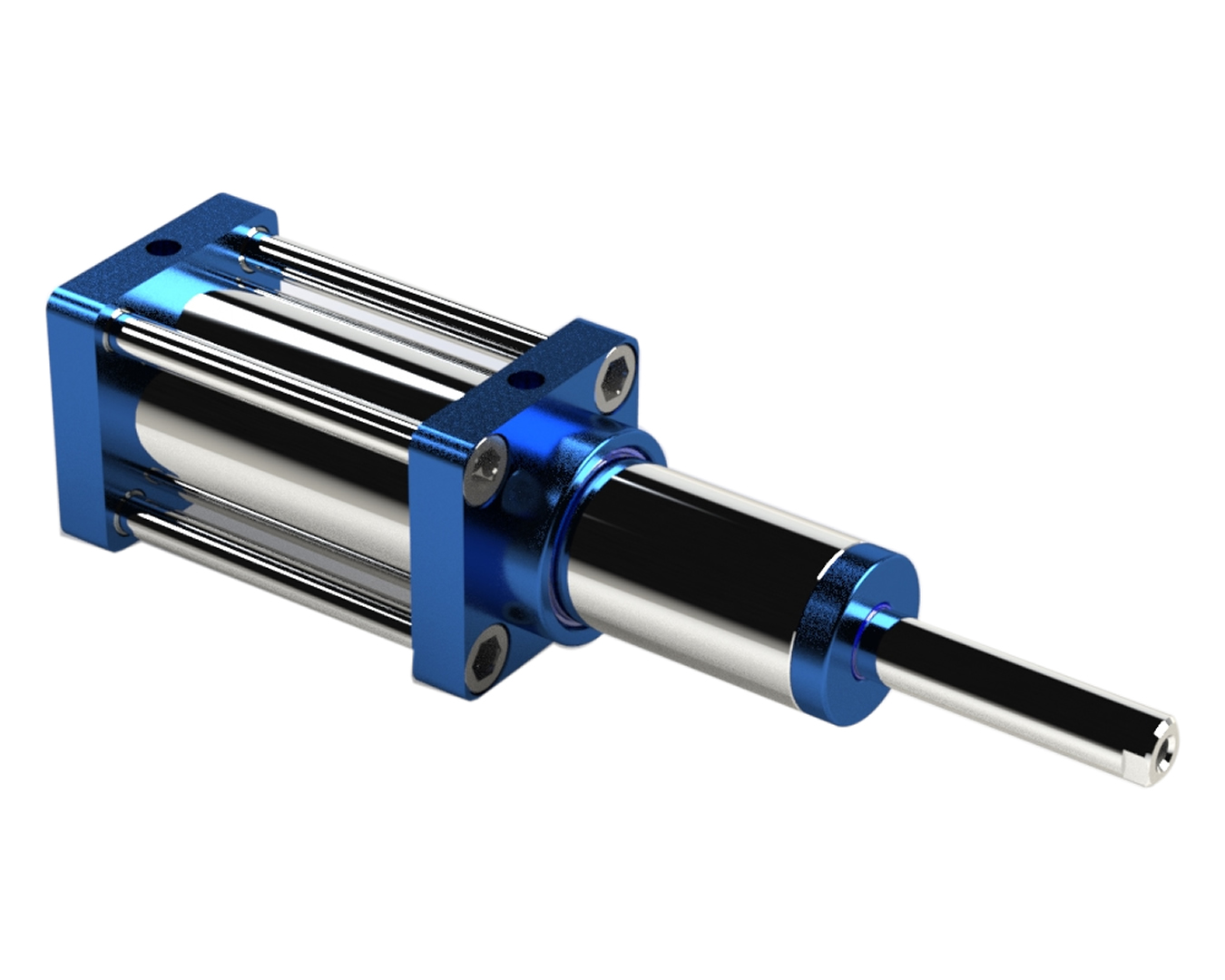

Large 300 ton small 5 ton long stroke single double acting telescopic hydraulic cylinder for sale

| Customer ID | Order Number | ||||||||

| Model | Application | ||||||||

| Data | Sample | Drawing | As per factory standard | Fluid Medium | Hydraulic Oil | Others | |||

| Cylinder Type | Piston | Plunger | Single Acting | Double Acting | Double Rod | Temperature | Below -20ºC | Normal | 80ºC to 120ºC |

| Oil Port | Location | Direction | Size | Force | Push | Pull | |||

| Usage Frequency | Working Continuously for Hours | Seal Requirement | |||||||

| Materials | As per factory standard | Special Requirements | |||||||

| Pressure Holding Requirements |

No Need | Yes, holding time for | |||||||

| Speed | mm/s | ||||||||

| Installation | Horizontal | Vertical | Angled or Arc | Air Bleed | No need | Head | End | ||

| Working Type | Working separately | Multiple cylinders working synchronously | Color | Customized | Per sample | Per factory standard | |||

| Cushion | No Need | Head end | Cap end | Head&cap | Non-adjustable | Adjustable | |||

| Accesories | Bearing | Fitting | Dust cover | Lock nut | Hose | Lock nut | Fixing bolt | Others | |

About US

Located in HangZhou City, ZheJiang province, center of North China Hydraulic industry, Lidingsheng (LDS) Lifting Machinery (ZheJiang ) Co., Ltd is specialized in hydraulic machinery, appliances and components, establishing an excellent reputation with superior quality and high-performance products since 2012. Covering an area of 16000 square meters, LDS provide Hydraulic Systems and parts including hydraulic power unit packs, mini hydraulic power unit pack, hydraulic cylinders, motors, gauges, filters, hydraulic valves and so on with modern standard workshop and advanced equipment.

With more than 80 series, 1,500 specifications products and 3 tech teams, LDS is capable of R&D and producing hydraulic system components, which are widely used in machinery industry, metallurgy industry, agricultural equipment, construction equipment, mining equipment, food industry, forestry equipment, trailers, excavators and other fields. Furthermore, LDS is capable of customizing hydraulic systems according to clients’ requirements on mounting styles, pressure ratings, sizes and configurations.

Please contact our sales manager and provide your custom requirements.

We will provide catalog with more products.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, CE, ISO9001, SGS |

|---|---|

| Pressure: | 3-100MPa |

| Work Temperature: | -10ºC to 200ºC Above |

| Acting Way: | Optional |

| Working Method: | Optional |

| Adjusted Form: | Optional |

| Customization: |

Available

|

|

|---|

How do telescopic cylinders contribute to energy-efficient equipment operation?

Telescopic cylinders play a significant role in promoting energy-efficient equipment operation. Here’s a detailed explanation:

Reduced energy consumption:

Telescopic cylinders are designed to minimize energy consumption during equipment operation. The hydraulic system of telescopic cylinders allows for precise control over the extension and retraction of the cylinder stages. This control enables the equipment to use the minimum amount of hydraulic fluid and energy required to achieve the desired movement or position.

Efficient force transmission:

Telescopic cylinders are engineered to efficiently transmit forces from the hydraulic system to the desired application. The telescopic design allows for a direct and linear transfer of force, reducing energy losses that can occur in more complex mechanical systems. This efficient force transmission ensures that the energy supplied to the telescopic cylinder is effectively utilized to perform the desired work.

Compactness and weight reduction:

Telescopic cylinders offer compactness in equipment design, which contributes to energy efficiency. By retracting the cylinder stages, the overall length of the equipment can be minimized, reducing weight and inertia. This reduction in weight and inertia requires less energy to start and stop the movement of the equipment, resulting in energy savings during operation.

Optimized design:

Telescopic cylinders are designed with efficiency in mind. Manufacturers consider factors such as the cylinder’s bore size, rod diameter, and overall construction to ensure optimal performance while minimizing energy requirements. By using lightweight and high-strength materials, optimizing the cylinder’s dimensions, and reducing internal friction, telescopic cylinders can operate efficiently and contribute to energy savings.

Controlled motion:

Telescopic cylinders provide precise and controlled motion, allowing equipment operators to perform tasks with accuracy and efficiency. The hydraulic control system in telescopic cylinders enables smooth and proportional extension and retraction, reducing the need for excessive force or multiple adjustments. This controlled motion prevents energy waste and ensures that the equipment operates efficiently.

Applications in energy-efficient equipment:

Telescopic cylinders are utilized in various energy-efficient equipment, such as hybrid or electric-powered machinery. These equipment types rely on the optimization of energy usage to minimize environmental impact and reduce operating costs. Telescopic cylinders contribute to these objectives by providing efficient force transmission, controlled motion, and compact design.

Furthermore, the integration of advanced technologies, such as electronic control systems, sensors, and feedback mechanisms, can enhance the energy efficiency of equipment that incorporates telescopic cylinders. These technologies allow for further optimization of hydraulic system performance, energy recovery, and intelligent control of equipment operations.

Overall, telescopic cylinders contribute to energy-efficient equipment operation through reduced energy consumption, efficient force transmission, compactness and weight reduction, optimized design, and controlled motion. By utilizing telescopic cylinders in equipment design and considering energy-efficient practices, industries can achieve more sustainable and economical operation.

Consulting with equipment manufacturers or industry experts can provide further insights into the energy-saving benefits and applications of telescopic cylinders in specific equipment types.

Can telescopic cylinders be used in aerial work platforms for extended reach?

Yes, telescopic cylinders are commonly used in aerial work platforms to achieve extended reach. Here’s a detailed explanation:

Increased working height:

Telescopic cylinders enable aerial work platforms to reach greater heights compared to other types of lifting mechanisms. The multi-stage design of telescopic cylinders allows for sequential extension, providing incremental increases in working height. This extended reach capability is crucial for accessing elevated areas such as construction sites, maintenance tasks, or elevated platforms.

Flexible reach adjustment:

Telescopic cylinders offer flexibility in adjusting the reach of aerial work platforms. By extending or retracting the cylinders, operators can modify the platform’s horizontal reach according to the specific job requirements. This flexibility allows for precise positioning of the platform, ensuring safe and efficient access to work areas at varying distances from the base.

Stability and load capacity:

Telescopic cylinders contribute to the stability and load capacity of aerial work platforms during extended reach operations. The cylinders provide structural support and help distribute the weight of the platform and the load being lifted. This load distribution ensures stability, minimizes the risk of tipping or tilting, and allows for safe operation even at maximum reach.

Controlled movements:

Telescopic cylinders enable controlled and smooth movements of aerial work platforms. The hydraulic control system regulates the extension and retraction of the cylinders, allowing for precise control over the platform’s vertical and horizontal motions. This controlled movement enhances operator safety, minimizes vibrations, and enables accurate positioning of the platform during extended reach tasks.

Compact design:

Telescopic cylinders offer a compact design that allows for efficient integration into aerial work platforms. The cylinders can be retracted when not in use, minimizing the space occupied by the lifting mechanism. This compactness allows for better maneuverability, improved accessibility in confined spaces, and efficient transportation of the aerial work platform.

Integration with other platform features:

Telescopic cylinders can be integrated with other features of aerial work platforms to enhance functionality. For example, they can be combined with articulating booms or rotating platforms to achieve versatile reach and positioning capabilities. This integration expands the range of applications for aerial work platforms, enabling them to navigate obstacles, reach over obstacles, or access difficult-to-reach areas.

Advantages of telescopic cylinders in aerial work platforms:

Telescopic cylinders offer several advantages when used in aerial work platforms for extended reach:

- Increased working height for accessing elevated areas

- Flexible reach adjustment for precise positioning

- Stability and load capacity during extended reach

- Controlled movements for operator safety

- Compact design for maneuverability and transportation

- Integration with other platform features for enhanced functionality

Overall, telescopic cylinders are a reliable and efficient choice for achieving extended reach in aerial work platforms. Their ability to increase working height, provide flexibility in reach adjustment, ensure stability, enable controlled movements, offer a compact design, and integrate with other platform features makes them well-suited for a wide range of aerial work applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in aerial work platforms.

Can telescopic cylinders be used for both lifting and pushing applications?

Yes, telescopic cylinders can be used for both lifting and pushing applications. Here’s a detailed explanation:

Lifting applications:

Telescopic cylinders are commonly employed in lifting applications where they provide the necessary force and stroke length to lift heavy loads. The nested structure of telescopic cylinders allows for extended stroke lengths while maintaining a compact retracted length. The hydraulic system supplies pressurized fluid to each stage, generating the force required for lifting. As the stages extend, the load is raised to the desired height.

Pushing applications:

In addition to lifting, telescopic cylinders can also be used for pushing applications. In these cases, the telescopic cylinder applies force in the opposite direction, typically to move or push objects or components. The hydraulic system supplies pressurized fluid to each stage, causing the stages to extend and exert a pushing force. The nested structure of the cylinder ensures that the force is transmitted through each stage, allowing for effective pushing.

Benefits of telescopic cylinders for lifting and pushing:

Telescopic cylinders offer several benefits for both lifting and pushing applications:

- Extended stroke length: Telescopic cylinders provide a longer stroke length compared to other types of cylinders, allowing for increased reach and movement in lifting and pushing operations.

- Compact retracted length: Despite their extended stroke length, telescopic cylinders have a compact retracted length. This is advantageous when space is limited or when a shorter cylinder length is desired.

- High force capabilities: Telescopic cylinders are designed to handle heavy loads and can generate significant force, making them suitable for lifting and pushing applications that require substantial power.

- Adjustability and flexibility: The hydraulic control system of telescopic cylinders allows for adjustability in terms of force, speed, and stroke length, providing flexibility and adaptability to different lifting and pushing requirements.

- Versatility: Telescopic cylinders can be used in various industries and applications, including construction, material handling, automotive, and more, making them versatile solutions for lifting and pushing tasks.

It’s important to consider the specific requirements of the lifting or pushing application and consult the manufacturer’s guidelines to ensure the proper selection, installation, and operation of telescopic cylinders in order to achieve safe and efficient performance.

editor by CX 2024-02-04

China high quality CZPT Customized Car Lift Telescopic Hydraulic Cylinder for Sale with Good quality

Product Description

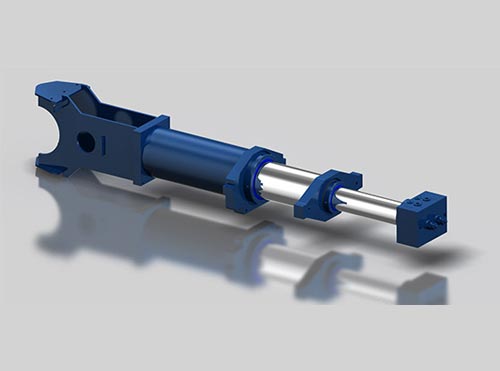

Densen customized car lift telescopic hydraulic cylinder for sale

Product Detail

| Name | Front end loader hydraulic cylinder |

| Working Pressure | 5800PSI |

| Bore Dia. | 2” 2.5” 3” 3.5” 4” 5” |

| Sealing Parts | From USA Herculesus |

| Heat Treatment | Quenching |

| Certificate | ISO9001:2008 |

| Service | OEM&ODM |

| Sample | For free |

| Quality Guarantee | 1 year |

| Package | Wooden box or iron box |

| Product Keywords | telescopic hydraulic cylinder for sale |

1. Seals kit: From USA, durable and hard-wearing with long service life.

2. Heat treatment: Quenching&Tempering which makes the piston rod super high hardness.

3. Cleaning: Ultrasonic cleaning

4. Cutting: High precision provided by automatic roller cutting machine.

5. Testing: Ultrasonic detector, spectrograph, CMM, metallography, chrome thickness tester.

6. Advantage: Simple structure & reliable work, easy maintenance & diverse connecting ways.

7. Plan: Different manufacturing plans for different customers.

8. MOQ: 10 PCS of clevis rod ends hydraulic cylinder

9. Lead time: 10~30 days depends on quantity & whether customized.

10. Warranty: Change a new 1 and we pay for the air freight in 3 years warranty time.

| Bore Size | B | C | D | E | E | Ports(NPT) |

| 2.00(50.80) | 2.125(53.98) | 1.125(28.58) | 2.07(52.58) | 1.00(25.40) | 2.50(63.50) | 3/8 |

| 2.50(63.50) | 2.125(53.98) | 1.125(28.58) | 2.07(52.58) | 1.00(25.40) | 3.00(76.20) | 1/2 |

| 3.00(76.20) | 2.125(53.98) | 1.125(28.58) | 2.07(52.58) | 1.00(25.40) | 3.50(88.90) | 1/2 |

| 3.50(88.90) | 2.125(53.98) | 1.125(28.58) | 2.07(52.58) | 1.00(25.40) | 4.00(101.60) | 1/2 |

| 4.00(101.60) | 2.000(50.80) | 1.125(28.58) | 2.07(52.58) | 1.00(25.40) | 4.50(114.30) | 1/2 |

| 5.00(127.00) | 2.000(50.80) | 1.500(38.10) | 2.44(61.98) | 1.00(25.40) | 5.50(139.70) | 1/2 |

1.Descriptions of Chrome Plated Shaft

| Size | 25.4~100mm |

| Length | 0.2m~2m |

| Material | 45#DIN CK45/JIS 45C |

| Tolerance | ISO f7 |

| Chrome Thickness | 25~30micron |

| Hardness of The Chrome Layer | 45~50HRC |

| Roughness | Ra0.4micron |

| Straightness | 0.2/1000mm |

| Yield Strength | ≥320Mpa |

| Tensile Strength | ≥580Mpa |

| Elongation | ≥15% |

| Supply Condition | 1.Hard chrome plated |

| 2.Induction hardened | |

| 3.Quenched&Tempered | |

| 4.Induction hardened with Q&T |

2.Chemical Composition

| Material | C% | Mn% | Si% | S% | P% | V% | Cr% |

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.04 | 0.035 | 0.035 | ||

| ST52 | 0.22 | 1.60 | 0.55 | 0.035 | 0.04 | ||

| ST37 | 0.17 | 1.60 | 0.55 | 0.04 | 0.04 | ||

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.10-0.50 | 0.035 | 0.035 | 0.10-0.20 | |

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.08-1.10 |

3.Mechanical Properties

| Material | T.S N/MM² | Y.S N/MM² | E%(MIN) | Condition |

| CK45 | 610 | 355 | 15 | Normalized |

| CK45 | 800 | 630 | 20 | Q+T |

| ST52 | 500 | 355 | 22 | Normalized |

| 20MnV6 | 750 | 590 | 12 | Normalized |

| 42CrMo4 | 980 | 850 | 14 | Q+T |

| 40Cr | 1000 | 800 | 10 | Q+T |

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within CHINAMFG group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Company Information

HangZhou New CHINAMFG Casting and Forging Company is the sales company of HangZhou CHINAMFG Group of Companies. Features of New CHINAMFG simply summarized as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. 9 related factories, over 50 joint-venture sub-contractors.

5. 25+ years of manufacturing experiences, 10+ years of exporting experience

6. 100% of products sold to overseas customers.

7. 50% of customer base is forturne 500 companies.

Densen Group Architecture:

Processing support

Casting Service:

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

New Densen offers multiple investment casting, sand casting, permanent casting, die casting, low pressure casting, ESR casting, lost foam casting, etc. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.01Kg to 150 tons separately.

Forging Service:

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. New CHINAMFG offers open die forging, closed die forging and ring forging services. Material can be steel, iron and non-ferrous. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.1Kg to 50,000Kgs.

Stamping Service:

Stamping (also known as punching) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

New Densen-XBL has more than 60 sets stamping equipments, is the designed supplier for several famous bands automotive companies, has the full ability to offer whole processes from blanking, stamping, welding, to electrostatic spraying for CHINAMFG customers.

Welding & Fabrication Service:

Welding Frabrication is the fabrication process of metal structures by cutting, bending, then assembling the components together through welding

New CHINAMFG offers manual arc welding ,laser welding and robot welding etc. UT, MPT,RT,PT all are available used for inspection, WPS &PQR (Welding Process Specification& Procedure Qualification Records) before production is available under clients’ requirement.

Machining Service:

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process.

New Densen-XBL has more than 60 sets precision machines incl. CNC center, boring, milling, lathing, etc., and more than 300 inspection instruments incl. 3 sets CMM with grade μm. Repeated tolerance can be maintained as 0.02mm. Meanwhile awarded by certificates ISO9001-2008; ISO/TS16949. New Densen-XBL specialized in high precise machining for small-middle-big metal components.

3rd Party Inspection:

New Densen worked as 3rd party inspection center besides its sister factories or sub-contractors’ self inspection, Offers process inspection, random inspection and before delivedry inspection services for material, mechanical, inside defects, dimentional, pressure, load, balance, surface treatment, visual inspection and test. Weekly project follow-up report together with pictures and videos, full quality inspection documentation available.

New CHINAMFG also designed as 3rd party inspection representative for several customers when their products made by other suppliers.

Contact us

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Clay Dry Sand |

|---|---|

| Casting Method: | Thermal Gravity Casting |

| Sand Core Type: | Resin Sand Core |

| Application: | Agricultural Machinery Parts |

| Machining: | CNC Machining |

| Material: | Steel |

| Customization: |

Available

|

|

|---|

Can telescopic cylinders be used in construction equipment like cranes?

Yes, telescopic cylinders are commonly used in construction equipment, including cranes. Here’s a detailed explanation:

Role in crane operation:

Telescopic cylinders play a critical role in the operation of cranes by enabling the extension and retraction of crane booms or arms. The telescopic cylinder is typically located at the base of the boom and is responsible for extending or retracting the boom sections, allowing the crane to reach different heights and distances.

Extension and retraction mechanism:

The telescopic cylinder in a crane consists of multiple stages or sleeves that retract inside one another. This nested design allows for compact storage when the boom is retracted, minimizing the overall length of the crane. When the cylinder extends, the stages slide out, increasing the length of the boom and providing the necessary reach. The synchronized extension and retraction of the stages are facilitated by the hydraulic control system.

Hydraulic control system:

The hydraulic control system in cranes is responsible for the precise and controlled extension and retraction of telescopic cylinders. It regulates the flow of hydraulic fluid to each stage of the cylinder, ensuring synchronized movement. By adjusting the flow rate, the operator can control the speed of extension and retraction, allowing for smooth and controlled operation of the crane.

Load handling capabilities:

Telescopic cylinders in cranes are designed to handle significant loads. They provide the necessary lifting force to support heavy loads at various boom lengths. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and to deliver the required lifting capacities.

Variety of crane types:

Telescopic cylinders are utilized in various types of cranes, including mobile cranes, truck-mounted cranes, and crawler cranes. These cranes are widely used in construction sites, infrastructure projects, and other lifting and material handling applications. The versatility of telescopic cylinders allows them to be integrated into different crane designs and configurations.

Advantages of telescopic cylinders in cranes:

Telescopic cylinders offer several advantages in crane applications. These include:

- Compactness: Telescopic cylinders enable the boom to be retracted to a compact size, making it easier to transport and maneuver the crane in confined spaces.

- Reach and height capabilities: The telescopic design allows the crane to achieve extended reach and height, enabling it to access elevated work areas or reach over obstacles.

- Efficiency: The controlled extension and retraction of telescopic cylinders contribute to efficient operation, allowing the crane to adjust its boom length quickly and precisely.

- Stability: Telescopic cylinders provide stability to the crane by supporting the boom and load, ensuring safe lifting and lowering of heavy objects.

Overall, telescopic cylinders are integral components of construction equipment like cranes. They enable the extension and retraction of crane booms, contribute to efficient and controlled operation, and enhance the lifting capabilities of cranes in various construction and material handling tasks.

It’s important to consult the crane manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

Can telescopic cylinders be used in forestry equipment for tree handling?

Yes, telescopic cylinders are commonly used in forestry equipment for tree handling tasks. Here’s a detailed explanation:

Tree felling and extraction:

Telescopic cylinders play a vital role in tree felling and extraction operations. They are utilized in equipment such as feller bunchers, harvesters, and forwarders. Telescopic cylinders provide the necessary force to cut down trees and extract them from the forest. The cylinders are used in combination with cutting heads, grapples, or clamps to grip, hold, and manipulate trees during the felling and extraction processes.

Boom and arm extension:

In forestry equipment, telescopic cylinders are employed to extend the booms and arms of machinery. This extension capability allows operators to reach trees located at various distances and heights, facilitating efficient tree handling. Telescopic cylinders enable the equipment to adapt to different tree sizes and positions, enhancing productivity and reducing manual labor.

Precise control:

Telescopic cylinders provide precise control over tree handling movements. The hydraulic control system allows operators to extend and retract the cylinders with accuracy, enabling controlled positioning of trees during felling, extraction, or stacking. This precise control is crucial for ensuring operator safety, preventing damage to the equipment or surrounding environment, and optimizing operational efficiency.

Load handling and stacking:

Telescopic cylinders support load handling and stacking operations in forestry equipment. They provide the necessary lifting force to handle tree logs and facilitate stacking for transportation or processing. The cylinders work in conjunction with grapples, forks, or other attachments to securely grip and manipulate tree logs during loading, unloading, or stacking activities.

Stability and balance:

Telescopic cylinders contribute to the stability and balance of forestry equipment during tree handling tasks. The controlled extension and retraction of the cylinders help maintain the proper weight distribution and prevent tipping or imbalance when handling heavy tree logs. This ensures the safety of operators and equipment in challenging forestry environments.

Advantages of telescopic cylinders in forestry equipment:

Telescopic cylinders offer several advantages in tree handling applications:

- Enhanced reach: Telescopic cylinders enable extended reach, allowing operators to access trees at various distances and heights.

- Precise control: The hydraulic control system provides precise control over tree handling movements, ensuring accurate positioning and manipulation.

- Efficient load handling: Telescopic cylinders provide the necessary force for lifting, holding, and stacking tree logs, improving efficiency in forestry operations.

- Adaptability: The extension capability of telescopic cylinders allows for adaptation to different tree sizes and positions, enhancing versatility in tree handling tasks.

- Stability and safety: Telescopic cylinders contribute to equipment stability and operator safety by maintaining proper weight distribution during tree handling activities.

Overall, telescopic cylinders are widely used in forestry equipment for tree handling tasks, offering extended reach, precise control, efficient load handling, adaptability, and stability. They enhance the productivity, safety, and efficiency of forestry operations.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in forestry equipment.

What industries commonly use telescopic cylinders in their applications?

Telescopic cylinders find applications in a wide range of industries where extended reach, height adjustment, or lifting capabilities are required. Here’s a detailed explanation:

Industries commonly using telescopic cylinders:

- Construction: The construction industry extensively utilizes telescopic cylinders in various equipment, including excavators, backhoes, loaders, cranes, and concrete pumps. Telescopic cylinders enable the extension and retraction of booms, arms, or buckets, providing the necessary reach, digging, and lifting capabilities in construction and earthmoving applications.

- Material Handling and Logistics: Telescopic cylinders are essential in industries involved in material handling and logistics operations. This includes applications such as cranes, forklifts, loaders, conveyor systems, and automated storage and retrieval systems. Telescopic cylinders enable the lifting, tilting, or extending movements required for efficient loading, unloading, and transportation of materials.

- Agriculture: The agricultural sector employs telescopic cylinders in various machinery, such as tractors, harvesters, sprayers, and irrigation systems. Telescopic cylinders facilitate height adjustment, folding/unfolding of implements, and movement of equipment parts, enhancing productivity and efficiency in agricultural operations.

- Transportation and Automotive: Telescopic cylinders play a role in the transportation and automotive industries. They are used in applications such as dump trucks, trailers, refuse trucks, car haulers, and hydraulic ramps. Telescopic cylinders enable the efficient tilting, dumping, or lifting of cargo, enhancing the functionality and versatility of transportation equipment.

- Marine and Offshore: The marine and offshore industries utilize telescopic cylinders in applications such as ship cranes, offshore platforms, and subsea equipment. Telescopic cylinders enable the extension and retraction of booms, arms, or lifting mechanisms, supporting various marine operations including cargo handling, offshore construction, and underwater exploration.

- Mining and Quarrying: In mining and quarrying operations, telescopic cylinders are employed in equipment such as excavators, loaders, and conveyor systems. They facilitate the necessary extension and retraction movements for digging, lifting, and conveying materials, enhancing productivity and efficiency in mining operations.

- Utilities and Energy: The utilities and energy sectors utilize telescopic cylinders in applications such as utility trucks, aerial platforms, power line maintenance equipment, and renewable energy installations. Telescopic cylinders enable the safe and efficient access to elevated work areas, equipment maintenance, and positioning of components in energy infrastructure.

- Manufacturing and Industrial: Telescopic cylinders are found in manufacturing and industrial environments in various machinery, including automated systems, assembly lines, robotic arms, and material handling equipment. They provide the necessary linear motion and reach for precise positioning, lifting, or transferring of components during manufacturing processes.

These are just a few examples of industries that commonly use telescopic cylinders in their applications. The versatility and efficiency of telescopic cylinders make them valuable components in numerous sectors where extended stroke lengths or compact retracted lengths are required.

It’s important to consult industry-specific guidelines and regulations to ensure the proper selection, installation, and maintenance of telescopic cylinders based on the specific application requirements.

editor by CX 2024-01-23

China Hot selling Scissor Lift Hydraulic Cylinders Mining Truck Suspension Oil Cylinder with GS vacuum pump for ac

Product Description

China Manufacturer Mining Dump Truck Spare Parts Front Rear Ride Oil Suspension Nitrogen Hydraulic Cylinder Made in China

Product Description:

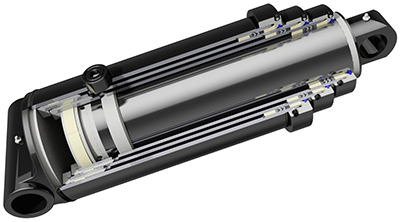

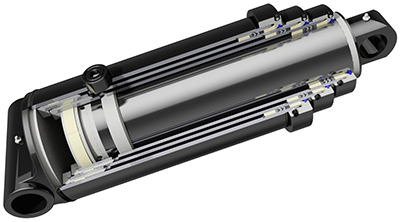

Widely used in equipment for Coal&mine,Engineering.

Special structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load.

The front and rear suspension cylinders can be analyzed and calculated based on the parameters provided by customers, and the stiffness and damping curves required by customers can be designed.

The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod.

Select heavy-duty sealing rings to meet the harsh working conditions of the mining area, ensuring excellent dustproof and sealing performance of the oil cylinder.

Select a wide series and high bearing capacity integrated guide ring, with strong lateral force resistance.

The interior of the lifting cylinder can be designed with a buffer structure to avoid excessive impact during lifting and lowering processes.

The steering cylinder can be equipped with a built-in displacement sensor to monitor the cylinder stroke in real-time.

The piston accumulator adopts a dual piston design, with high and low pressure chambers to meet various road conditions.

The reliable sealing structure design of the piston accumulator ensures the separation of oil and gas.

Product Display:

Front suspension cylinder for mining dump truck

Rear suspension cylinder for mining dump truck

Specifications:

| Item | Specifications |

| Bore Diameter | 150mm-450mm,Customized |

| Rod Diameter | 120mm-400mm,Customized |

| Stroke | 200-500mm,Customized |

| Working Pressure | 7-45Mpa,Customized |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Tube&Barrel | High tensile cold drawn tube, precision honed for extended seal life |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Certificate | ISO9001,CE,SGS. |

| Colour | Yellow,Red,Black,Pink,Customized |

| Packaging | metal case;plywood case;carton or as requirement |

| MOQ | 1pcs,According to products |

| Brand | tianjian or customer’s logo |

| Service | OEM & ODM |

| Production Time | Based on order quantity. normally 30-45days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Mounting Method:

Appliactions:Mining Dump Truck

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

About US:Certificates

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

Our Customers

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 3000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can hydraulic cylinders be retrofitted onto existing equipment for improved functionality?

Yes, hydraulic cylinders can be retrofitted onto existing equipment to enhance functionality and performance. Retrofitting hydraulic cylinders onto existing machinery or equipment offers several benefits, including increased power, improved control, enhanced precision, and versatility. Here’s a detailed explanation of how hydraulic cylinders can be retrofitted onto existing equipment for improved functionality:

1. Increased Power:

– Retrofitting hydraulic cylinders allows for the addition of hydraulic power to the existing equipment. By integrating hydraulic cylinders, the equipment can generate higher forces and handle heavier loads. This increased power enables the equipment to perform tasks that were previously challenging or impossible. For example, a retrofit hydraulic cylinder on a crane can enhance its lifting capacity and enable it to handle heavier loads more efficiently.

2. Improved Control:

– Hydraulic cylinders provide precise control over the motion and positioning of equipment. By retrofitting hydraulic cylinders, operators gain better control over the speed, force, and direction of movement. The addition of hydraulic control valves and a hydraulic power unit allows for fine-tuning of the equipment’s operation. Improved control facilitates safer and more efficient operation, reducing the risk of damage and improving overall productivity.

3. Enhanced Precision:

– Retrofitting hydraulic cylinders onto existing equipment can significantly improve precision and accuracy. Hydraulic systems offer precise control over movement, enabling smooth and controlled motion. This enhanced precision is beneficial in applications where precise positioning or repetitive movements are required. For instance, retrofitting hydraulic cylinders onto a robotic arm can enhance its accuracy and repeatability, making it more suitable for tasks that demand high precision.

4. Versatility and Adaptability:

– Retrofitting hydraulic cylinders can increase the versatility and adaptability of existing equipment. Hydraulic systems can be easily integrated with various types of machinery, allowing for the utilization of hydraulic power across different applications. The modular nature of hydraulic components facilitates the retrofitting process, enabling the equipment to perform a broader range of tasks. This versatility is particularly advantageous in industries where equipment needs to adapt to changing operational requirements.

5. Retrofit Kits and Customization:

– Manufacturers often provide retrofit kits that include all the necessary components for integrating hydraulic cylinders onto existing equipment. These kits typically consist of hydraulic cylinders, mounting brackets, hoses, fittings, control valves, and other required accessories. Retrofit kits simplify the retrofitting process and ensure compatibility between the hydraulic components and the existing equipment. Additionally, manufacturers can offer customization options to tailor the retrofit solution to specific equipment and application needs.

6. Cost-Effective Solution:

– Retrofitting hydraulic cylinders onto existing equipment can be a cost-effective solution compared to purchasing new machinery. By leveraging the existing equipment’s structural framework and mechanical components, the overall cost of upgrading can be reduced. Retrofitting also minimizes downtime since the equipment does not need to be completely replaced. Furthermore, the improved functionality and performance resulting from the retrofit can lead to increased productivity and cost savings in the long run.

7. Professional Installation and Expertise:

– Retrofitting hydraulic cylinders onto existing equipment often requires professional installation and expertise. Working with experienced hydraulic system integrators or manufacturers ensures proper installation, compatibility, and optimal performance of the retrofit solution. These professionals can assess the existing equipment, recommend suitable hydraulic components, and carry out the retrofitting process efficiently. Their knowledge and expertise contribute to the successful integration of hydraulic cylinders and the overall improvement of equipment functionality.

In summary, hydraulic cylinders can indeed be retrofitted onto existing equipment to improve functionality. This retrofitting process offers advantages such as increased power, improved control, enhanced precision, versatility, cost-effectiveness, and access to retrofit kits and customization options. By retrofitting hydraulic cylinders, existing equipment can be upgraded to meet evolving operational needs, extend its lifespan, and enhance overall performance.

Ensuring Stable Performance of Hydraulic Cylinders Under Fluctuating Loads

Hydraulic cylinders are designed to provide stable performance even under fluctuating loads. They achieve this through various mechanisms and features that allow for efficient load control and compensation. Let’s explore how hydraulic cylinders ensure stable performance under fluctuating loads:

- Piston Design: The piston inside the hydraulic cylinder plays a crucial role in load control. It is typically equipped with seals and rings that prevent leakage of hydraulic fluid and ensure effective transfer of force. The piston design may incorporate features such as stepped or tandem pistons, which provide enhanced load-bearing capabilities and improved stability by distributing the load across multiple surfaces.

- Cylinder Cushioning: Hydraulic cylinders often incorporate cushioning mechanisms to minimize the impact and shock caused by fluctuating loads. Cushioning can be achieved through various methods, such as adjustable cushion screws, hydraulic cushioning valves, or elastomeric cushioning rings. These mechanisms slow down the piston’s movement near the end of the stroke, reducing the impact and preventing sudden stops that could lead to instability.

- Pressure Compensation: Fluctuating loads can result in pressure variations within the hydraulic system. To ensure stable performance, hydraulic cylinders are equipped with pressure compensation mechanisms. These mechanisms maintain a consistent pressure level in the system, regardless of load changes. Pressure compensation can be achieved through the use of pressure relief valves, compensating pistons, or pressure-compensated flow control valves.

- Flow Control: Hydraulic cylinders often incorporate flow control valves to regulate the speed of the cylinder’s movement. By controlling the flow rate of hydraulic fluid, the cylinder’s motion can be adjusted to match the changing load conditions. Flow control valves allow for smooth and controlled movement, preventing abrupt changes that could lead to instability.

- Feedback Systems: To ensure stable performance under fluctuating loads, hydraulic cylinders can be integrated with feedback systems. These systems provide real-time information on the cylinder’s position, velocity, and force. By continuously monitoring these parameters, the hydraulic system can make immediate adjustments to maintain stability and compensate for load fluctuations. Feedback systems can include position sensors, pressure sensors, or load sensors, depending on the specific application.

- Proper Sizing and Selection: Ensuring stable performance under fluctuating loads starts with proper sizing and selection of hydraulic cylinders. It is crucial to choose cylinders with appropriate bore size, rod diameter, and stroke length to match the anticipated load conditions. Oversized or undersized cylinders can lead to instability and reduced performance. Proper sizing also involves considering factors such as the required force, speed, and duty cycle of the application.

In summary, hydraulic cylinders ensure stable performance under fluctuating loads through features such as piston design, cushioning mechanisms, pressure compensation, flow control, feedback systems, and proper sizing and selection. These mechanisms and considerations allow hydraulic cylinders to provide consistent and controlled movement, even in dynamic load conditions, resulting in reliable and stable performance.

How do hydraulic cylinders contribute to the efficiency of heavy machinery like excavators?

Hydraulic cylinders play a crucial role in enhancing the efficiency and performance of heavy machinery, such as excavators. These powerful hydraulic actuators enable excavators to perform various tasks efficiently and effectively. Here’s a detailed explanation of how hydraulic cylinders contribute to the efficiency of heavy machinery like excavators:

1. Force and Power:

– Hydraulic cylinders provide the necessary force and power required for the excavation process. They convert hydraulic energy from the hydraulic fluid into linear mechanical force, allowing the excavator to exert significant pushing and pulling forces. The force generated by hydraulic cylinders enables the digging arm or boom of the excavator to penetrate and break through tough materials, such as soil, rocks, or concrete, with ease and efficiency.

2. Precise Control:

– Hydraulic cylinders offer precise control over the movement of excavator components. By regulating the flow of hydraulic fluid to the cylinders, operators can control the speed, direction, and positioning of the excavator’s arm, boom, bucket, and other attachments. This precise control allows operators to perform delicate operations, such as fine grading or precise material placement, with accuracy and efficiency.

3. Versatility and Adaptability:

– Hydraulic cylinders enable excavators to perform a wide range of tasks by facilitating the quick and easy interchangeability of attachments. Excavators can be equipped with various specialized attachments, including buckets, breakers, grapples, and augers, which can be efficiently connected and disconnected using hydraulic cylinders. This versatility and adaptability enhance the efficiency of excavators by enabling them to tackle different tasks without the need for extensive manual adjustments or downtime.

4. Increased Productivity:

– The power and control provided by hydraulic cylinders significantly increase the productivity of excavators. Excavators equipped with hydraulic cylinders can complete tasks more quickly and efficiently compared to manual or mechanically-driven machinery. The precise control over movements allows for faster cycle times, reduced idle time, and improved overall productivity on the worksite.

5. Enhanced Digging and Lifting Capabilities:

– Hydraulic cylinders enable excavators to perform digging and lifting operations with enhanced capabilities. The force generated by hydraulic cylinders allows excavators to dig deeper and lift heavier loads compared to other types of machinery. This increased digging and lifting capacity contributes to the efficiency of excavators by reducing the number of passes required to complete a task and improving overall productivity.

6. Durability and Reliability:

– Hydraulic cylinders are designed to withstand heavy loads, challenging operating conditions, and frequent use. They are built with robust materials, such as high-strength steel, and undergo stringent quality control measures during manufacturing. The durability and reliability of hydraulic cylinders ensure that excavators can operate efficiently even in demanding environments, minimizing downtime and maximizing productivity.

7. Energy Efficiency:

– Hydraulic systems, including hydraulic cylinders, are known for their energy efficiency. Hydraulic cylinders can deliver high force outputs while consuming relatively low amounts of hydraulic fluid. This energy efficiency translates to lower fuel consumption and reduced operating costs for excavators. The efficient use of hydraulic power contributes to the overall efficiency and sustainability of heavy machinery operations.

8. Safety:

– Hydraulic cylinders play a vital role in ensuring the safety of excavator operations. They provide controlled and predictable movements, reducing the risk of sudden or uncontrolled motions. The precise control offered by hydraulic cylinders allows operators to perform tasks safely and accurately, minimizing the chances of accidents or damage to the machinery or surrounding environment.

Overall, hydraulic cylinders are essential components that significantly contribute to the efficiency of heavy machinery like excavators. By providing force, precise control, versatility, increased productivity, enhanced capabilities, durability, energy efficiency, and safety, hydraulic cylinders enable excavators to perform a wide range of tasks efficiently and effectively in various industries, including construction, mining, and landscaping.

editor by CX 2024-01-19

China Standard Straight Trip Scissor Lift Hydraulic Cylinders Mining Truck Oil Suspension Nitrogen Cylinder vacuum pump ac system

Product Description

China Manufacturer Mining Dump Truck Spare Parts Front Rear Ride Oil Suspension Nitrogen Hydraulic Cylinder Made in China

Product Description:

Widely used in equipment for Coal&mine,Engineering.

Special structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load.

The front and rear suspension cylinders can be analyzed and calculated based on the parameters provided by customers, and the stiffness and damping curves required by customers can be designed.

The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod.

Select heavy-duty sealing rings to meet the harsh working conditions of the mining area, ensuring excellent dustproof and sealing performance of the oil cylinder.

Select a wide series and high bearing capacity integrated guide ring, with strong lateral force resistance.

The interior of the lifting cylinder can be designed with a buffer structure to avoid excessive impact during lifting and lowering processes.

The steering cylinder can be equipped with a built-in displacement sensor to monitor the cylinder stroke in real-time.

The piston accumulator adopts a dual piston design, with high and low pressure chambers to meet various road conditions.

The reliable sealing structure design of the piston accumulator ensures the separation of oil and gas.

Product Display:

Front suspension cylinder for mining dump truck

Rear suspension cylinder for mining dump truck

Specifications:

| Item | Specifications |

| Bore Diameter | 150mm-450mm,Customized |

| Rod Diameter | 120mm-400mm,Customized |

| Stroke | 200-500mm,Customized |

| Working Pressure | 7-45Mpa,Customized |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Tube&Barrel | High tensile cold drawn tube, precision honed for extended seal life |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Certificate | ISO9001,CE,SGS. |

| Colour | Yellow,Red,Black,Pink,Customized |

| Packaging | metal case;plywood case;carton or as requirement |

| MOQ | 1pcs,According to products |

| Brand | tianjian or customer’s logo |

| Service | OEM & ODM |

| Production Time | Based on order quantity. normally 30-45days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Mounting Method:

Appliactions:Mining Dump Truck

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

About US:Certificates

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

Our Customers

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 3000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do hydraulic cylinders handle variations in temperature and harsh operating environments?

Hydraulic cylinders are designed to handle variations in temperature and harsh operating environments by incorporating specific features and materials that ensure their durability, reliability, and performance. The ability of hydraulic cylinders to withstand extreme temperatures, corrosive environments, and other harsh conditions is crucial for their successful operation in a wide range of applications. Here’s a detailed explanation of how hydraulic cylinders handle variations in temperature and harsh operating environments:

1. Temperature Range:

– Hydraulic cylinders are designed to operate within a specified temperature range. The materials used in their construction, such as cylinder barrels, pistons, seals, and lubricants, are selected to withstand the anticipated temperature variations. Specialized seals and O-rings made from materials like nitrile, Viton, or polyurethane are used to maintain their sealing properties over a wide temperature range. Heat-resistant coatings or thermal insulation may be applied to certain components to protect them from high temperatures.

2. Thermal Expansion:

– Hydraulic cylinders are designed to accommodate thermal expansion and contraction that occurs with temperature changes. The materials used in their construction have different coefficients of thermal expansion, allowing the cylinder components to expand or contract at a similar rate. This design consideration prevents excessive stress, binding, or leakage that could result from thermal expansion or contraction.

3. Heat Dissipation:

– In applications where hydraulic cylinders are subjected to high temperatures, heat dissipation mechanisms are employed to prevent overheating. Cooling fins or heat sinks may be incorporated into the cylinder design to increase the surface area for heat transfer. In some cases, external cooling methods such as air or liquid cooling systems can be used to maintain optimal operating temperatures.

4. Corrosion Resistance:

– Hydraulic cylinders used in harsh operating environments are constructed from materials that exhibit excellent corrosion resistance. Stainless steel, chrome-plated steel, or other corrosion-resistant alloys are commonly used for cylinder components exposed to corrosive substances or environments. Additionally, surface treatments such as coatings, plating, or specialized paints can provide an extra layer of protection against corrosion.

5. Sealing Systems:

– Hydraulic cylinders employ sealing systems that are specifically designed to withstand harsh operating environments. The seals used in hydraulic cylinders are selected based on their resistance to temperature extremes, chemicals, abrasion, and other environmental factors. Specialized seal designs, such as wiper seals, rod seals, or high-temperature seals, are utilized to maintain effective sealing and prevent contamination of the hydraulic fluid.

6. Lubrication:

– Proper lubrication is essential for the smooth operation and longevity of hydraulic cylinders, particularly in harsh operating environments. Lubricants are selected based on their ability to withstand high temperatures, resist oxidation, and provide effective lubrication under extreme conditions. Regular maintenance and lubrication practices ensure that the cylinder components continue to operate smoothly and reduce the effects of wear and friction.

7. Robust Construction:

– Hydraulic cylinders designed for harsh operating environments are built with robust construction techniques to withstand the rigors of such conditions. The cylinder barrels, rods, and other components are manufactured to meet strict quality and durability standards. Welded or bolted construction methods are employed to ensure the structural integrity of the cylinders. Reinforcements, such as flanges or tie rods, may be added to enhance the cylinder’s strength and resistance to external forces.

8. Environmental Protection:

– Hydraulic cylinders can be equipped with additional protective features to shield them from harsh operating environments. Protective covers, boots, or bellows can be used to prevent contaminants, debris, or moisture from entering the cylinder and compromising its performance. These protective measures help extend the service life of hydraulic cylinders in demanding conditions.

9. Compliance with Standards:

– Hydraulic cylinders manufactured for specific industries or applications often comply with industry standards or regulations related to operating temperature ranges, environmental conditions, or safety requirements. Compliance with these standards ensures that hydraulic cylinders are designed and tested to meet the specific demands of their intended operating environments.

In summary, hydraulic cylinders are designed to handle variations in temperature and harsh operating environments by incorporating suitable materials, thermal expansion considerations, heat dissipation mechanisms, corrosion-resistant components, specialized sealing systems, proper lubrication, robust construction techniques, protective features, and compliance with industry standards. These design considerations and features enable hydraulic cylinders to operate reliably and effectively in a wide range of demanding applications and environmental conditions.

Utilizing Hydraulic Cylinders in Conjunction with Alternative Energy Sources

Hydraulic cylinders can indeed be used in conjunction with alternative energy sources. The versatile nature of hydraulic systems allows them to be integrated with various alternative energy technologies to enhance efficiency, control, and power generation. Let’s explore some examples of how hydraulic cylinders can be utilized alongside alternative energy sources:

- Hydraulic Energy Storage: Hydraulic cylinders can be employed in energy storage systems that utilize alternative energy sources such as renewable sources (e.g., solar or wind) or waste energy recovery. These systems convert excess energy into hydraulic potential energy by pumping fluid into a high-pressure accumulator. When the energy is needed, the pressurized fluid is released, driving the hydraulic cylinder and generating mechanical power.

- Wave and Tidal Energy Conversion: Hydraulic cylinders can be utilized in wave and tidal energy conversion systems. These systems harness the power of ocean waves or tidal currents and convert it into usable energy. Hydraulic cylinders, along with associated pumps and valves, can be used to capture and control the energy from the waves or tides, driving the cylinders and generating mechanical power or producing electricity.

- Hydroelectric Power Generation: Hydraulic cylinders play a crucial role in traditional hydroelectric power generation. However, alternative approaches such as small-scale or micro-hydropower systems can also benefit from hydraulic cylinders. These systems utilize natural or man-made water flows to drive turbines connected to hydraulic cylinders, which then convert the hydraulic energy into mechanical power or electricity.

- Hydraulic Actuation in Wind Turbines: Hydraulic cylinders can be employed in wind turbines to enhance performance and control. For example, hydraulic pitch control systems use hydraulic cylinders to adjust the pitch angle of wind turbine blades, optimizing their aerodynamic performance based on wind conditions. This allows for efficient power generation and protection against excessive wind loads.

- Geothermal Energy Extraction: Geothermal energy extraction involves utilizing the natural heat from the Earth’s interior to generate power. Hydraulic cylinders can be utilized in geothermal systems to control and regulate fluid flow, allowing for efficient extraction and utilization of geothermal energy. They can also be used in geothermal heat pumps for heating and cooling applications.

In summary, hydraulic cylinders can be effectively utilized in conjunction with alternative energy sources to enhance energy storage, power generation, and control. Whether it’s through hydraulic energy storage systems, wave and tidal energy conversion, hydroelectric power generation, hydraulic actuation in wind turbines, or geothermal energy extraction, hydraulic cylinders offer versatile and efficient solutions for harnessing and utilizing alternative energy sources.

How do hydraulic cylinders generate force and motion using hydraulic fluid?

Hydraulic cylinders generate force and motion by utilizing the principles of fluid mechanics, specifically Pascal’s law, in conjunction with the properties of hydraulic fluid. The process involves the conversion of hydraulic energy into mechanical force and linear motion. Here’s a detailed explanation of how hydraulic cylinders achieve this:

1. Pascal’s Law:

– Hydraulic cylinders operate based on Pascal’s law, which states that when pressure is applied to a fluid in a confined space, it is transmitted equally in all directions. In the context of hydraulic cylinders, this means that when hydraulic fluid is pressurized, the force is evenly distributed throughout the fluid and transmitted to all surfaces in contact with the fluid.

2. Hydraulic Fluid and Pressure:

– Hydraulic systems use a specialized fluid, typically hydraulic oil, as the working medium. This fluid is stored in a reservoir and circulated through the system by a hydraulic pump. The pump pressurizes the fluid, creating hydraulic pressure that can be controlled and directed to various components, including hydraulic cylinders.

3. Cylinder Design and Components:

– Hydraulic cylinders consist of several key components, including a cylindrical barrel, a piston, a piston rod, and various seals. The barrel is a hollow tube that houses the piston and allows for fluid flow. The piston divides the cylinder into two chambers: the rod side and the cap side. The piston rod extends from the piston and provides a connection point for external loads. Seals are used to prevent fluid leakage and maintain hydraulic pressure within the cylinder.

4. Fluid Input and Motion:

– To generate force and motion, hydraulic fluid is directed into one side of the cylinder, creating pressure on the corresponding surface of the piston. This pressure is transmitted through the fluid to the other side of the piston.

5. Force Generation:

– The force generated by a hydraulic cylinder is a result of the pressure applied to a specific surface area of the piston. The force exerted by the hydraulic cylinder can be calculated using the formula: Force = Pressure × Area. The area is determined by the diameter of the piston or the piston rod, depending on which side of the cylinder the fluid is acting upon.

6. Linear Motion:

– As the pressurized hydraulic fluid acts on the piston, it generates a force that moves the piston in a linear direction within the cylinder. This linear motion is transferred to the piston rod, which extends or retracts accordingly. The piston rod can be connected to external components or machinery, allowing the generated force to perform various tasks, such as lifting, pushing, pulling, or controlling mechanisms.

7. Control and Regulation:

– The force and motion generated by hydraulic cylinders can be controlled and regulated by adjusting the flow of hydraulic fluid into the cylinder. By regulating the flow rate, pressure, and direction of the fluid, the speed, force, and direction of the cylinder’s movement can be precisely controlled. This control allows for accurate positioning, smooth operation, and synchronization of multiple cylinders in complex machinery.

8. Return and Recirculation of Fluid:

– After the hydraulic cylinder completes its stroke, the hydraulic fluid on the opposite side of the piston needs to be returned to the reservoir. This is typically achieved through hydraulic valves that control the flow direction, allowing the fluid to return and be recirculated in the system for further use.

In summary, hydraulic cylinders generate force and motion by utilizing the principles of Pascal’s law. Pressurized hydraulic fluid acts on the piston, creating force that moves the piston in a linear direction. This linear motion is transferred to the piston rod, allowing the generated force to perform various tasks. By controlling the flow of hydraulic fluid, the force and motion of hydraulic cylinders can be precisely regulated, contributing to their versatility and wide range of applications in machinery.

editor by CX 2024-01-17

China Hot selling Hydraulic RAM Engineering Hydraulic Cylinders for Tractor Loader Concrete Pump Truck Factory Basic Customization Double Acting Long Stroke Telescopic Lift with Good quality

Product Description

Product Description

Works Hydraulic Technology(HangZhou)Co.,Ltd is famous for its hydraulic equipment and hydraulic system. Since the establishment, it deeply rooted in the hydraulic, electric control and mechanical related industries, focusing on the research and development, production, sales of electromechanical and hydraulic products.

Otherwise, it adapts to the market demand and provides users with comprehensive electromechanical and hydraulic products and services in more than 10 industries, including metallurgy, aviation, engineering machinery, water conservancy and hydro power, machine tools, pharmaceuticals, logistics, plastics, etc. Starting from the market applications of hydraulic, electronic control and mechanical engineering, it has successfully completed hundreds of sets of hydraulic systems, lubrication system engineering and hydraulic cylinders for many domestic and overseas customers.

OFFERING: Various kinds of hydraulic oil cylinders, solutions for hydraulic systems, hydraulic stations.

Product Parameters

| Hydraulic RAM Engineering Hydraulic Cylinders for Tractor Loader Concrete Pump Truck Factory Basic Customization Double Acting Long Stroke Telescopic Lift | |

| Bore diameter | 30-1500mm |

| Shaft diameter | 12-1000mm |

| Working pressure | 0.3-16MPa |

| Working media | Hydraulic oil |

| Operation temperature | -30ºC~+60ºC |

| Valid Stroke | 32-1800mm |

| Structure | Piston type, telescopic type, plunger type |

| Cylinder body material | Stainless steel 304/316, ST52, CK45, 4140, duplex 2205, etc. |

| Acting | Single acting, double acting |

| Paint | Blue, black red, orange, yellow, green, or customized |

| Seal | Parker, Merkel, Nok, Hallite, etc. |

| Application | Metallurgy, engineering machinery, mine, agriculture, CNC machine, logistics, power, etc. |

Product Features

This series of cylinders are widely used in hydraulic systems of industrial vehicles such as forklifts, trucks and aerial work platforms, and perform operations such as steering, lifting, tilting, and side shifting of the main engine. This series of cylinders is reasonable in structure, reliable in operation and easy to maintain. The advantages of the series hydraulic cylinders are as below:

High Performance

1. On average, about 20 seconds faster than similar products.

2. Lower friction resistance, improved the integrated work efficiency.

3. Multiple mounting ways, convenient for transportation.

4. Fine processing details, wear resistance and durable for use.

High Strength

1. Joint development of new high-strength steel pipes with CHINAMFG steel manufacturers.

2. Increased work pressure.

Electroplated Chrome CHINAMFG Rod

Reduce friction factor, reduce abrasion, increase using life time.

High Density Welding of Circumferential Seams

Increase the high pressure sealing airtightness, improve using safety.

No Oil Leakage

High quality polyurethane sealing ring, integrated welding body, universal bearing, never worry about oil leakage, more durable.

Advantages

Strong technical team

Hydraulic system designer, electrical control designer, 3D simulation designer, production management, etc.

12 hydraulic engineers, 3 automation engineers, 10 technicians, 6 commissioning engineers.

One-stop factory

Manufacture standard, non-standard hydraulic oil cylinders, hydraulic cylinder components, also provide solutions for integrated hydraulic systems.

Scale Production

Adopt advanced manufacturing devices, realize scale production and lower cost, lower wholesale price.

Popular Models We Have:

Application

Hydraulic cylinders are widely used in engineering machinery, molds, automobiles, mines, metallurgy, aviation, ships, agriculture, environmental protection and other industries.

Our company not only manufactures standard hydraulic oil cylinders, like thin type oil cylinder, magnetic induction oil cylinder, paper rack machine oil cylinder, pit machine oil cylinder, light weight hydraulic cylinder, heavy duty hydraulic cylinder, round type oil cylinder, mechanical oil cylinder, engineering hydraulic cylinder, but also non-standard hydraulic oil cylinders, providing solutions for hydraulic systems.

We own strong technical team, they are respectively engaged in hydraulic system design, electrical control design, production management, etc. Providing 3D simulation designing as per customer’s requirement until you are satisfied.

Company Profile

HangZhou Packway Technology Development Co., LTD, Founded in March 2005, has been at the forefront of innovation, constantly striving to develop cutting-edge technologies and solutions. We currently operate 3 subsidiary companies, each connected with different sectors of the machinery market.

History of the 3 branches:

HangZhou Superworker Technology Co., LTD, established in June 2011, is an innovative enterprise specialized in industrial packaging. The main products and services include: automatic mechanical equipment (steel belt /PET belt strapping machine, clipping belt machine, marking spray machine, labeling machine, etc.), intelligent industrial packaging unit (coil, wire, plate, etc.), intelligent coil logistics system, transformation and upgrading services of similar products, repair and maintenance services of related equipment, supply of wearing parts and consumables. The SUPERWORKER has strong R&D strength and Customers from both domestic and international markets.

With the wide application of automation equipment, HangZhou Dagongren Electric Cylinder Technology Co., Ltd came into being in 2014. We are engaged in designing and manufacturing linear motion products, including servo/stepper motor electric cylinders, linear actuators, multi-degree of freedom platforms, synchronization lifting platforms, VR simulators, etc, with features of high positioning accuracy, low noise, and long life. Our products have been widely used in automated warehousing, robotics, automation equipment, medical equipment, and AGV, vehicles, etc.