Product Description

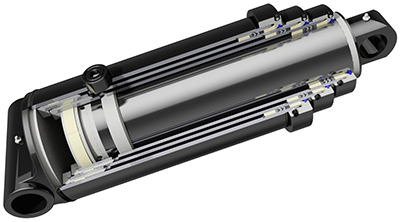

CAT 777 Spare Part Double Acting Hoist Telescopic Multistage Hydraulic Cylinder

Product Description:

Special structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load.

The front and rear suspension cylinders can be analyzed and calculated based on the parameters provided by the customer, and the stiffness and damping curves required by the customer can be designed.

The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod.

Select heavy-duty sealing rings to meet the harsh working conditions in the mining area, ensuring excellent dust and sealing performance of the oil cylinder.

Select a wide series and high load-bearing integrated guide ring, with strong lateral force resistance ability.

The internal buffer structure of the lifting cylinder can be designed to avoid excessive impact during lifting and lowering processes.

The steering cylinder can be equipped with a displacement sensor to monitor the cylinder stroke in real-time.

The piston accumulator adopts a dual piston design, with high and low pressure chambers to meet various road conditions.

The reliable sealing structure design of the piston accumulator ensures the separation of oil and gas.

Product Display:

Specifications:

| Item | Specifications |

| Bore Diameter | 100mm-450mm,Customized |

| Rod Diameter | 80mm-400mm,Customized |

| Stroke | 200mm-500mm,Customized |

| Working Pressure | 7-45Mpa,Customized |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Tube&Barrel | High tensile cold drawn tube, precision honed for extended seal life |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Certificate | ISO9001,CE,SGS. |

| Colour | Yellow,Red,Black,Pink,Customized |

| Packaging | metal case;plywood case;carton or as requirement |

| MOQ | 1pcs,According to products |

| Brand | tianjian or customer’s logo |

| Service | OEM & ODM |

| Production Time | Based on order quantity. normally 30-45days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Mounting Method:

Appliactions:Mining Dump Truck

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

About US:Certificates

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

Our Customers

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What safety considerations are important when using machinery with telescopic cylinders?

When using machinery with telescopic cylinders, several safety considerations should be taken into account. Here’s a detailed explanation:

Operator training and awareness:

Proper training and awareness are crucial for operators working with machinery equipped with telescopic cylinders. Operators should receive comprehensive training on the safe operation of the machinery, including the correct use of telescopic cylinders. They should be familiar with the controls, safety features, and best practices to ensure their own safety and the safety of others in the vicinity.

Regular inspection and maintenance:

Regular inspection and maintenance of telescopic cylinders are essential for ensuring safe operation. Cylinders should be inspected for signs of wear, damage, or leakage. Any issues should be addressed promptly to prevent potential failures or accidents. Lubrication, if required, should be performed according to the manufacturer’s recommendations.

Proper load capacity and stability:

It is important to ensure that the machinery and telescopic cylinders are used within their specified load capacity. Exceeding the load capacity can lead to instability, loss of control, or structural failure. Proper weight distribution and secure attachment of loads are also critical to maintaining stability during operation.

Safe work environment:

Creating a safe work environment is essential when using machinery with telescopic cylinders. This includes maintaining clear and unobstructed pathways for the machinery’s movement, removing potential hazards, and implementing appropriate safety measures such as barriers, signage, or warning systems to prevent unauthorized access or accidental contact with the machinery or its cylinders.

Emergency stop and shutdown procedures:

Emergency stop and shutdown procedures should be clearly communicated to operators. They should be trained on how to quickly and effectively stop the machinery’s operation in case of an emergency or when a safety hazard is detected. These procedures should be regularly reviewed and practiced to ensure a prompt response in critical situations.

Proper guarding and protection:

Telescopic cylinders should be adequately guarded to prevent accidental contact and potential injuries. Guarding may include physical barriers, shields, or sensors that detect the presence of personnel or objects in the cylinder’s path. Additionally, operators should wear appropriate personal protective equipment (PPE) as recommended for the specific task and working environment.

Compliance with regulations and standards:

It is important to ensure compliance with relevant regulations and safety standards when using machinery with telescopic cylinders. These regulations and standards may address aspects such as design, installation, operation, maintenance, and inspection of the machinery and its components. Adhering to these requirements helps mitigate risks and promotes a safe working environment.

Regular risk assessments:

Regular risk assessments should be conducted to identify and address potential hazards associated with the machinery and telescopic cylinders. This includes assessing risks related to operation, maintenance, equipment failure, environmental conditions, and human factors. Mitigation measures should be implemented based on the findings of the risk assessment.

Overall, safety considerations when using machinery with telescopic cylinders involve operator training, regular inspection and maintenance, load capacity and stability, safe work environment, emergency procedures, guarding and protection, compliance with regulations, and regular risk assessments. By addressing these considerations, the risks associated with operating machinery with telescopic cylinders can be minimized, promoting a safer working environment.

It’s important to consult the machinery manufacturer’s guidelines, safety manuals, and applicable regulations to ensure comprehensive understanding and implementation of safety practices.

How do telescopic cylinders handle variations in cylinder size and capacity?

Telescopic cylinders are designed to handle variations in cylinder size and capacity effectively. Here’s a detailed explanation:

Modular design:

Telescopic cylinders feature a modular design that allows for flexibility in cylinder size and capacity. They consist of multiple stages or sections that retract inside one another, similar to a telescope. The number of stages can vary depending on the desired extended length and capacity of the cylinder. This modular design enables telescopic cylinders to be customized according to specific requirements.

Variable stroke length:

Telescopic cylinders offer the advantage of variable stroke length. The stroke length refers to the distance the cylinder can extend and retract. By adjusting the stroke length, the effective size and capacity of the telescopic cylinder can be modified. This flexibility allows for accommodating variations in the size and capacity requirements of different applications.

Increased capacity with additional stages:

Telescopic cylinders can handle variations in capacity by adding more stages to the cylinder. Each stage contributes to the overall capacity of the cylinder. By including additional stages, the cylinder’s capacity can be increased to handle higher loads or operate in more demanding conditions. This scalability makes telescopic cylinders suitable for a wide range of applications with varying capacity needs.

Proportional force distribution:

Telescopic cylinders distribute the applied force proportionally across the stages. As the cylinder extends, each stage contributes to supporting the load and transmitting the force. The force distribution ensures that the load is evenly distributed among the stages, allowing the cylinder to handle variations in capacity effectively.

Hydraulic control system:

Telescopic cylinders rely on a hydraulic control system for operation. The system allows for precise control over the extension and retraction of each stage. By adjusting the hydraulic pressure and flow, operators can regulate the movement and force exerted by the cylinder, ensuring optimal performance and capacity utilization.

Overall, telescopic cylinders handle variations in cylinder size and capacity through their modular design, variable stroke length, ability to add stages for increased capacity, proportional force distribution, and hydraulic control system. These features make telescopic cylinders adaptable to different applications and enable them to effectively handle varying size and capacity requirements.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the size, capacity, and operational considerations of telescopic cylinders.

What is a telescopic cylinder and how does it work?

A telescopic cylinder is a type of hydraulic cylinder that consists of multiple nested stages or sections that can extend and retract, similar to a telescope. Here’s a detailed explanation:

A telescopic cylinder is primarily used when a long stroke length is required while maintaining a compact retracted length. It is commonly used in applications such as dump trucks, cranes, aerial platforms, and other equipment that require extended reach or height adjustment. Here’s how a telescopic cylinder works:

- Structure: A telescopic cylinder consists of a series of cylindrical stages or sleeves that are progressively nested inside one another. These stages are typically made of high-strength steel or aluminum alloy. The number of stages can vary depending on the specific design and application.

- Extension and Retraction: When the telescopic cylinder is in the retracted position, the stages are nested inside one another, with the smallest stage located at the base. To extend the cylinder, hydraulic fluid is supplied to the base of the cylinder, creating pressure that pushes the smallest stage outwards. As the smallest stage extends, it exposes the next larger stage, which is then pushed out by the hydraulic pressure. This process continues until all the stages have extended, resulting in a longer overall stroke length.

- Locking Mechanism: Telescopic cylinders often incorporate a locking mechanism to secure the extended stages in position. This mechanism ensures stability and prevents unintentional retraction of the cylinder under load. The locking mechanism can be mechanical, hydraulic, or a combination of both, depending on the design and application requirements.

- Retraction: To retract the telescopic cylinder, hydraulic fluid is supplied to the opposite side of the cylinder, typically to the largest stage. The hydraulic pressure acts on the largest stage, retracting it first. As each stage retracts, it nests inside the next smaller stage until the cylinder is fully retracted to its original compact length.

- Control and Stability: The extension and retraction of a telescopic cylinder are controlled by a hydraulic system. By regulating the flow and pressure of the hydraulic fluid, operators can precisely control the extension and retraction speed of the cylinder. The nested design of the stages provides stability and load-bearing capacity, allowing the telescopic cylinder to handle substantial loads.

The use of telescopic cylinders offers several benefits:

- Extended Stroke Length: Telescopic cylinders provide a significantly longer stroke length compared to traditional single-stage cylinders, enabling extended reach or height adjustment without increasing the overall size of the cylinder.

- Compact Design: The nested structure of telescopic cylinders allows for a compact retracted length, making them suitable for applications with space constraints.

- Versatility: Telescopic cylinders can be customized to meet specific stroke length requirements. The number of stages can be adjusted, and the cylinders can be designed for different load capacities and working conditions.

- Efficient Operation: The controlled extension and retraction of telescopic cylinders enable precise load handling and positioning, improving operational efficiency.

Overall, a telescopic cylinder is a hydraulic cylinder with nested stages that can extend and retract, providing an extended stroke length while maintaining a compact retracted length. Its structure and operation make it ideal for applications requiring long reach or height adjustment.

It’s important to follow the manufacturer’s guidelines and specifications for the telescopic cylinder, including proper maintenance and inspection, to ensure its safe and reliable operation.

<img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l1.webp" alt="China Custom Tianjian Stroke Dump Truck Mining Piston Hydraulic Double Acting Hoist Cylinder with ISO9001 manufacturer “><img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l2.webp" alt="China Custom Tianjian Stroke Dump Truck Mining Piston Hydraulic Double Acting Hoist Cylinder with ISO9001 manufacturer “>

editor by Dream 2024-10-11

China Professional Piston Type Tianjian Cylinders Oil Stroke Hydraulic Cylinder with ISO9001 Factory Price vacuum pump

Product Description

Factory Custom Mass-Produced Long Stroke Hydraulic Cylinders for Ultra-high Pressure Filter Press

| Item | Specifications |

| Bore diameter | 160mm-580mm,customizable |

| Bod diameter | 110mm-410mm,customizable |

| Stroke | 400mm-3000mm,customizable |

| Working Pressure | 7-45Mpa,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,Customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,Customizable |

| Seal Type | Parker,NOK, Hallite GAPI or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Colour | Red,White,Pink,Yellow,Bule,etc,Customizable |

| Packaging | Metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Product Display:

Compact structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load.

The hydraulic cylinder adopts a multi-channel sealing design to ensure stable operation of the sealing system.

Designed with a wide temperature resistance range (-25 ºC to+120 ºC), and able to provide customized services for higher or lower temperature oil cylinders.

The inner hole of the guide sleeve adopts a high load-bearing guide structure to maximize the lateral load resistance of the oil cylinder.

The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod.

Work pressure, size specifications, installation methods, etc. can be customized according to customer needs for design.

Appliactions:Industrial Engineering,Filter Press .

Mounting Method:

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection of Mechanical Properties of Raw Materials

Process Inspection

Final Testing

Packing & Delivery:

About US:

Our Certificate

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Our Main Customers

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic cylinders be used for precise operations like CNC machining or molding?

Yes, hydraulic cylinders can be used for precise operations like CNC machining or molding. While hydraulic systems are commonly associated with heavy-duty applications, they can also provide the necessary precision and control required for precise operations in CNC machining and molding processes. Here’s a detailed explanation of how hydraulic cylinders can be utilized for such precise operations:

1. Force and Control:

– Hydraulic cylinders are capable of generating substantial force, which is essential for precise operations in CNC machining and molding. By using hydraulic pressure, the cylinders can deliver the required force to cut or shape materials accurately or exert pressure for molding operations. The hydraulic system allows precise control over the force applied, ensuring consistent and reliable performance.

2. Adjustable Speed and Positioning:

– Hydraulic cylinders offer adjustable speed and precise positioning capabilities, making them suitable for precise operations. By controlling the flow of hydraulic fluid, the speed of the cylinder’s movement can be adjusted according to specific requirements. This adaptability allows for fine-tuning the machining or molding process, achieving the desired precision in material removal or shaping. Hydraulic systems also enable accurate positioning of tools or molds, ensuring precise operations.

3. Integrated Feedback Systems:

– Advanced hydraulic systems can incorporate feedback sensors and control mechanisms to enhance precision in CNC machining and molding. These sensors provide real-time information about the position, speed, and force exerted by the hydraulic cylinders. The control system processes this data and adjusts the flow of hydraulic fluid accordingly, allowing for precise and accurate control over the operations. The feedback systems help maintain consistent performance and compensate for any deviations, ensuring high precision.

4. Damping and Vibration Control:

– Hydraulic cylinders can be equipped with damping mechanisms to minimize vibrations and ensure stability during CNC machining or molding operations. Vibrations can negatively impact precision by causing tool chatter or material deformation. By incorporating cushioning or damping features, hydraulic cylinders help absorb shocks and suppress vibrations, resulting in smoother and more accurate operations.

5. Customization and Adaptability:

– Hydraulic cylinders can be customized and adapted to meet the specific requirements of CNC machining or molding processes. Engineers can design cylinders with unique dimensions, stroke lengths, mounting options, and sealing arrangements to fit into equipment or systems with precise specifications. Customized hydraulic cylinders ensure optimal performance and compatibility for precise operations, enabling seamless integration into CNC machines or molding equipment.

6. Energy Efficiency:

– Hydraulic systems can be designed to be energy-efficient, contributing to cost savings in CNC machining or molding operations. By utilizing variable speed pumps, efficient control valves, and well-designed hydraulic circuits, energy consumption can be optimized. This efficiency reduces heat generation, leading to improved stability and precision in operations while minimizing energy costs.

7. Maintenance and Calibration:

– Regular maintenance and calibration of hydraulic systems are essential to maintain their precision in CNC machining or molding applications. Proper lubrication, inspection of seals, and replacement of worn-out components help ensure optimal performance. Regular calibration of control systems and feedback sensors ensures accurate readings and reliable operation, contributing to precision in machining or molding processes.

In summary, hydraulic cylinders can be effectively used for precise operations like CNC machining or molding. Their ability to generate substantial force, adjustable speed and positioning, integration with feedback systems, damping and vibration control, customization and adaptability, energy efficiency, and proper maintenance contribute to achieving the required precision in these operations. By leveraging the strengths of hydraulic systems, manufacturers can enhance the accuracy and reliability of CNC machining or molding processes, resulting in high-quality products and improved productivity.

How do hydraulic cylinders contribute to the efficiency of agricultural tasks like plowing?

Hydraulic cylinders play a crucial role in improving the efficiency of agricultural tasks, including plowing. These cylinders provide several benefits that enhance the performance and productivity of agricultural machinery. Let’s explore how hydraulic cylinders contribute to the efficiency of plowing and other agricultural tasks:

- Powerful Force Generation: Hydraulic cylinders are capable of generating high forces, which is essential for tasks like plowing. The hydraulic system supplies pressurized fluid to the cylinders, converting hydraulic energy into mechanical force. This force is then utilized to drive plow blades through the soil, overcoming resistance and facilitating efficient soil penetration. The power generated by hydraulic cylinders ensures effective plowing, even in tough or compacted soil conditions.

- Adjustable Working Depth: Hydraulic cylinders allow for easy and precise adjustment of the plow’s working depth. By controlling the extension or retraction of the hydraulic cylinder, farmers can adjust the depth of the plow blades according to soil conditions, crop requirements, or their specific preferences. This adjustability enhances efficiency by ensuring optimal soil tillage and minimizing unnecessary energy expenditure. Farmers can adapt the plowing depth to different field areas, optimizing the use of resources and promoting uniform crop growth.

- Responsive Control: Hydraulic systems offer highly responsive control, enabling farmers to make quick adjustments during plowing operations. Hydraulic cylinders respond rapidly to changes in hydraulic pressure and valve settings, allowing for immediate modifications in the plow’s position, depth, or angle. This responsiveness enhances efficiency by facilitating on-the-go adjustments based on soil variations, obstacles, or changing field conditions. Farmers can maintain precise control over the plow’s performance, ensuring effective soil tillage and minimizing the risk of crop damage.

- Implement Versatility: Hydraulic cylinders enable the attachment of various implements to agricultural machinery, expanding their functionality and versatility. In the context of plowing, hydraulic cylinders allow for the attachment and detachment of plow blades or other tillage implements. This versatility enables farmers to adapt their equipment to different soil types, field sizes, or specific plowing requirements. By using hydraulic cylinders, farmers can easily switch between different implements, optimizing their equipment for specific tasks and maximizing efficiency.

- Efficient Time Management: Hydraulic cylinders contribute to time efficiency in agricultural tasks like plowing. With hydraulic systems, farmers can operate plows at higher speeds while maintaining control and precision. The responsive nature of hydraulic cylinders allows for efficient turning, maneuvering, and repositioning of plows, minimizing downtime and optimizing field coverage. This time efficiency translates into increased productivity and reduced overall operational costs. Farmers can accomplish plowing tasks more quickly, allowing them to cover larger field areas in less time.

In summary, hydraulic cylinders significantly contribute to the efficiency of agricultural tasks like plowing. Through powerful force generation, adjustable working depth, responsive control, implement versatility, and efficient time management, hydraulic systems equipped with cylinders enhance the performance and productivity of agricultural machinery. These contributions allow farmers to accomplish plowing tasks more effectively, optimize field operations, and achieve improved overall efficiency in their agricultural practices.

Which industries and machinery commonly use hydraulic cylinders for power transmission?

Hydraulic cylinders are widely used in various industries and machinery for power transmission due to their ability to generate high force, precise control, and reliable operation. They play a crucial role in converting hydraulic energy into mechanical force and motion. Here are the detailed industries and machinery that commonly utilize hydraulic cylinders for power transmission:

1. Construction and Heavy Equipment:

– Hydraulic cylinders are extensively used in the construction industry for tasks involving heavy lifting, pushing, and positioning. They are employed in cranes, excavators, loaders, bulldozers, and other heavy equipment to lift and move heavy loads, operate attachments, and manipulate construction materials. Hydraulic cylinders provide the necessary force and control for tasks such as lifting and lowering buckets, extending and retracting booms, and tilting blades.

2. Material Handling and Logistics:

– In material handling and logistics applications, hydraulic cylinders are vital components for the movement and manipulation of goods. They are used in forklifts, stackers, palletizers, and conveyor systems to lift, lower, and position loads with precision. Hydraulic cylinders enable the efficient transfer of heavy objects, facilitate stacking and sorting operations, and contribute to the smooth operation of material handling equipment.

3. Agriculture and Farming:

– The agricultural industry relies on hydraulic cylinders for various tasks in farming equipment. Tractors, harvesters, sprayers, and loaders utilize hydraulic cylinders to perform functions such as lifting and lowering implements, adjusting the position of attachments, and steering operations. Hydraulic cylinders enable efficient and precise control in tasks like plowing, tilling, harvesting, and baling, enhancing productivity and convenience in agricultural operations.

4. Mining and Extraction:

– Hydraulic cylinders are extensively utilized in the mining and extraction industry for their ability to handle heavy loads and operate in challenging environments. They are employed in mining equipment such as dump trucks, loaders, and excavators for tasks like ore extraction, rock breaking, and material transport. Hydraulic cylinders provide the force required for excavating, loading, and dumping operations, contributing to the efficiency and productivity of mining operations.

5. Manufacturing and Industrial Machinery:

– Hydraulic cylinders are an integral part of various manufacturing and industrial machinery. They are utilized in presses, stamping machines, injection molding machines, and metal forming equipment to apply force for shaping, bending, and pressing operations. Hydraulic cylinders enable precise control over the force and speed required for manufacturing processes, ensuring accurate and consistent results.

6. Automotive and Transportation:

– Hydraulic cylinders are employed in the automotive and transportation industry for a range of applications. They are used in vehicle lifting systems, such as car lifts and hydraulic jacks, for maintenance and repairs. Hydraulic cylinders are also utilized in bus doors, truck tailgates, and cargo handling systems to provide controlled movement and positioning. Additionally, hydraulic suspension systems in trucks, buses, and trailers use hydraulic cylinders for load leveling and stability.

7. Aerospace and Aviation:

– The aerospace and aviation industry relies on hydraulic cylinders for various applications, including aircraft landing gear, wing flaps, and flight control systems. Hydraulic cylinders provide the necessary force and precise control for extending and retracting landing gear, adjusting wing surfaces, and actuating control surfaces. They contribute to the safe and efficient operation of aircraft, ensuring reliable performance during takeoff, landing, and flight maneuvers.

8. Marine and Offshore:

– Hydraulic cylinders are utilized in marine and offshore equipment for a wide range of tasks. They are found in ship and boat steering systems, hatch covers, cranes, winches, and anchor handling equipment. Hydraulic cylinders enable precise control and powerful force transmission in maritime applications, supporting navigation, cargo handling, and offshore operations.

In summary, hydraulic cylinders are commonly used in industries such as construction, material handling, agriculture, mining, manufacturing, automotive, aerospace, marine, and more. They are integral components in machinery and equipment that require reliable power transmission, precise control, and the ability to handle heavy loads. The versatile nature of hydraulic cylinders allows them to be adapted to various applications, contributing to increased efficiency, productivity, and safety in numerous industries.

<img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l1.webp" alt="China Professional Piston Type Tianjian Cylinders Oil Stroke Hydraulic Cylinder with ISO9001 Factory Price vacuum pump “><img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l2.webp" alt="China Professional Piston Type Tianjian Cylinders Oil Stroke Hydraulic Cylinder with ISO9001 Factory Price vacuum pump “>

editor by Dream 2024-10-10

China OEM Manufacturer Custom Heavy Duty Single Double Acting Piston Telescopic Hydraulic Press Cylinder with Solenoid Valve with Hot selling

Product Description

Product Description

Hydraulic press cylinder:

Hetlock(ZheJiang )Machinery Co.,Ltd. is familiar with the all kinds of hydraulic press machine working condition.

Due to the hydraulic cylinder long-term work under high pressure and short-term impact pressure, have highly requirements of holding pressure performance, So, for the selection of sealing form, The design of buffer structure, The strength of all the part of hydraulic cylinder, and highly requirements of Welding performance.

We have the professional calculation software for checking the strength of each part. To ensure the hydraulic cylinder service life time and reliability.

Our products have applications in:

- Steel industry press;

- Hydro forming press;

- Automotive industry press;

- Plastic or rubber industry press;

- Deep drawing press;

- Molding press;

- Multi purpose press;

- Blanking press;

- Recycling industry press;

- Stamping press;

- Etc.

Product Parameters

| Material | Carbon steel, Alloy steel, Stainless steel |

| Honed tube | 20-2500mm, Heat treatment, honing, rolling |

| Piston rod | 10-2000mm ,tempering, plated nickel, Chromium or ceramic |

| Working Pressure | 5-300Mpa |

| Seals | Parker,Merkel,Hallite |

| Technology | Bosch CHINAMFG and Parker |

| Coating | Sandblasting, primer, middle paint, finish paint |

| Temperature range | -40ºC to +300ºC |

| Work medium | Hydraulic Oil |

| Piston speed | maximum 2m/s |

| Mounting style | Earrings, flange, foot mounting, screw thread. |

Product Application

Company Show

HETLOCK is a professional manufacturer of hydraulic cylinders in China, Founded in 1998, located in the international city of ZheJiang . Our plant is nearly 20000 square meter& We have 135 Employees including 11 experienced engineers and technical staff,More than 1800 type of hydraulic cylinder designed in every year. We can produce various kinds of hydraulic cylinders according to customer requirements.

The inside diameter of hydraulic cylinders can achieve the maximum 2500mm;

The hydraulic cylinders operating pressure can achieve the maximum 300MPa.

FAQ

Q1:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q2: How many years of production experience do you have?

A: We have over 20 years of production experience.

Q3: Can it be customized?

A: Both standard and non-standard products can be customized.

Q4: How to ensure product quality?

A: We strictly follow the quality process for production and 100% inspection of each batch of products.

Q5: What services can you provide?

A: According to customer requirements, we can provide a one-stop solution from design, production, and delivery to meet their needs.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What safety considerations are important when using machinery with telescopic cylinders?

When using machinery with telescopic cylinders, several safety considerations should be taken into account. Here’s a detailed explanation:

Operator training and awareness:

Proper training and awareness are crucial for operators working with machinery equipped with telescopic cylinders. Operators should receive comprehensive training on the safe operation of the machinery, including the correct use of telescopic cylinders. They should be familiar with the controls, safety features, and best practices to ensure their own safety and the safety of others in the vicinity.

Regular inspection and maintenance:

Regular inspection and maintenance of telescopic cylinders are essential for ensuring safe operation. Cylinders should be inspected for signs of wear, damage, or leakage. Any issues should be addressed promptly to prevent potential failures or accidents. Lubrication, if required, should be performed according to the manufacturer’s recommendations.

Proper load capacity and stability:

It is important to ensure that the machinery and telescopic cylinders are used within their specified load capacity. Exceeding the load capacity can lead to instability, loss of control, or structural failure. Proper weight distribution and secure attachment of loads are also critical to maintaining stability during operation.

Safe work environment:

Creating a safe work environment is essential when using machinery with telescopic cylinders. This includes maintaining clear and unobstructed pathways for the machinery’s movement, removing potential hazards, and implementing appropriate safety measures such as barriers, signage, or warning systems to prevent unauthorized access or accidental contact with the machinery or its cylinders.

Emergency stop and shutdown procedures:

Emergency stop and shutdown procedures should be clearly communicated to operators. They should be trained on how to quickly and effectively stop the machinery’s operation in case of an emergency or when a safety hazard is detected. These procedures should be regularly reviewed and practiced to ensure a prompt response in critical situations.

Proper guarding and protection:

Telescopic cylinders should be adequately guarded to prevent accidental contact and potential injuries. Guarding may include physical barriers, shields, or sensors that detect the presence of personnel or objects in the cylinder’s path. Additionally, operators should wear appropriate personal protective equipment (PPE) as recommended for the specific task and working environment.

Compliance with regulations and standards:

It is important to ensure compliance with relevant regulations and safety standards when using machinery with telescopic cylinders. These regulations and standards may address aspects such as design, installation, operation, maintenance, and inspection of the machinery and its components. Adhering to these requirements helps mitigate risks and promotes a safe working environment.

Regular risk assessments:

Regular risk assessments should be conducted to identify and address potential hazards associated with the machinery and telescopic cylinders. This includes assessing risks related to operation, maintenance, equipment failure, environmental conditions, and human factors. Mitigation measures should be implemented based on the findings of the risk assessment.

Overall, safety considerations when using machinery with telescopic cylinders involve operator training, regular inspection and maintenance, load capacity and stability, safe work environment, emergency procedures, guarding and protection, compliance with regulations, and regular risk assessments. By addressing these considerations, the risks associated with operating machinery with telescopic cylinders can be minimized, promoting a safer working environment.

It’s important to consult the machinery manufacturer’s guidelines, safety manuals, and applicable regulations to ensure comprehensive understanding and implementation of safety practices.

How do telescopic cylinders handle variations in hydraulic seal technology?

Telescopic cylinders are designed to accommodate variations in hydraulic seal technology. Here’s a detailed explanation:

Compatibility with different seal types:

Telescopic cylinders are engineered to be compatible with various types of hydraulic seals available in the market. Whether it’s a standard O-ring seal, lip seal, V-ring seal, or any other seal design, the cylinder’s construction takes into account the requirements of different seal technologies. This compatibility ensures that telescopic cylinders can effectively handle variations in hydraulic seal technology.

Seal retention and protection:

Telescopic cylinders incorporate features to retain and protect hydraulic seals. The cylinder design includes seal grooves, seal retainers, or other mechanisms that securely hold the seals in place, preventing their displacement or damage during operation. This seal retention and protection mechanism ensures the longevity and effectiveness of the seals, regardless of the specific seal technology used.

Seal lubrication and contamination prevention:

Telescopic cylinders address the lubrication and contamination concerns associated with different seal technologies. The cylinder’s hydraulic system is designed to provide proper lubrication to the seals, ensuring smooth movement and reducing friction. Additionally, measures such as seal scrapers or wipers are implemented to prevent the ingress of contaminants, such as dust, dirt, or moisture, which could compromise the performance of the seals. These lubrication and contamination prevention mechanisms cater to the specific requirements of various seal technologies.

Seal replacement and maintenance:

Telescopic cylinders are designed to facilitate seal replacement and maintenance procedures. The cylinder construction allows for easy access to the seals, simplifying the replacement process when necessary. This feature is advantageous when dealing with different seal technologies, as it enables swift and efficient maintenance, regardless of the specific seal design being used.

Adaptability to seal advancements:

Telescopic cylinder designs often incorporate adaptability to advancements in hydraulic seal technology. Manufacturers continuously develop new seal technologies to improve performance, durability, and efficiency. Telescopic cylinders are designed with flexibility to accommodate future advancements, ensuring compatibility with emerging seal technologies and allowing for upgrade possibilities without significant modifications to the cylinder itself.

Overall, telescopic cylinders are engineered to handle variations in hydraulic seal technology through compatibility with different seal types, seal retention and protection features, seal lubrication and contamination prevention mechanisms, ease of seal replacement and maintenance, and adaptability to seal advancements. These design considerations ensure that telescopic cylinders can effectively work with different seal technologies, providing reliable and efficient performance in hydraulic systems.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the recommended seal types and maintenance practices for telescopic cylinders.

What are the components and design features of a telescopic cylinder?

A telescopic cylinder consists of various components and incorporates specific design features to enable its functionality and performance. Here’s a detailed explanation:

Components of a telescopic cylinder:

- Stages or Sleeves: A telescopic cylinder comprises multiple stages or sleeves that are nested inside one another. These stages are usually cylindrical in shape and are made of high-strength steel or aluminum alloy. The number of stages can vary depending on the specific design and application requirements.

- Piston and Rod: Each stage of a telescopic cylinder has its own piston and rod assembly. The piston is located inside the stage and is connected to the rod, which extends through the center of the stage. The piston and rod assembly is responsible for generating the linear motion of each stage during extension and retraction.

- Seals: Sealing elements, such as O-rings or lip seals, are used to ensure a hydraulic seal between the stages. These seals prevent leakage of hydraulic fluid and maintain pressure within each stage during operation. The seals also help to protect the internal components from contaminants.

- Locking Mechanism: Telescopic cylinders often incorporate a locking mechanism to secure the extended stages in position. This mechanism ensures stability and prevents unintentional retraction of the cylinder under load. The locking mechanism can be mechanical, hydraulic, or a combination of both, depending on the design and application requirements.

- Guides and Bearings: To maintain proper alignment and minimize friction between the stages, telescopic cylinders may include guides and bearings. These components facilitate smooth extension and retraction of the stages and provide structural support.

- Hydraulic Connections: Telescopic cylinders have hydraulic connections to supply hydraulic fluid for extension and retraction. These connections typically include ports or fittings for the inlet and outlet of hydraulic fluid. Flexible hydraulic hoses or tubing are used to connect the cylinder to the hydraulic system of the equipment.

Design features of a telescopic cylinder:

- Nested Structure: The nested structure is a fundamental design feature of a telescopic cylinder. It allows the stages to extend and retract within one another, enabling a longer stroke length while maintaining a compact retracted length.

- Articulation Capability: Some telescopic cylinders incorporate articulation capability, which allows the cylinder to adjust its angle or position relative to the equipment. This feature enhances the versatility of the cylinder and enables it to adapt to different mounting orientations and working conditions.

- Internal Flow Paths: The design of a telescopic cylinder includes internal flow paths that facilitate the controlled flow of hydraulic fluid between the stages during extension and retraction. These flow paths ensure synchronized movement of the stages and contribute to the overall performance and stability of the cylinder.

- Surface Treatment: The external surfaces of telescopic cylinders are often treated or coated to provide protection against corrosion, wear, and environmental elements. Common surface treatments include painting, powder coating, or electroplating.

These components and design features work together to enable the functionality, reliability, and performance of a telescopic cylinder. It’s important to consult the manufacturer’s guidelines and specifications for proper installation, operation, and maintenance of the telescopic cylinder based on the specific application requirements.

<img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l1.webp" alt="China OEM Manufacturer Custom Heavy Duty Single Double Acting Piston Telescopic Hydraulic Press Cylinder with Solenoid Valve with Hot selling “><img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l2.webp" alt="China OEM Manufacturer Custom Heavy Duty Single Double Acting Piston Telescopic Hydraulic Press Cylinder with Solenoid Valve with Hot selling “>

editor by Dream 2024-10-09

China Professional Large Bore Hydraulic Piston 2 Stage Telescopic Double Acting Cylinder vacuum pump ac

Product Description

Product Description

Renewable energy hydraulic cylinder:

HETLOCK comply with development and demand of the times. We are further study in the field of renewable energy. Has been successfully to entered many customer in the field of wind power.

And reference to bridge jack-up experience of rise and fall. Creatively to installed the hydraulic valve into the hydraulic cylinder directly. Improve the stability when hydraulic cylinder ruining. And to avoid the hydraulic cylinder suddenly fall off due to tube crack.

Our products have applications in:

- Wind energy;

- Nuclear energy;

- Solar Thermal energy;

- Marine energy

- Etc.

Product Parameters

| Material | Carbon steel, Alloy steel, Stainless steel |

| Honed tube | 20-2500mm, Heat treatment, honing, rolling |

| Piston rod | 10-2000mm ,tempering, plated nickel, Chromium or ceramic |

| Working Pressure | 5-300Mpa |

| Seals | Parker,Merkel,Hallite |

| Technology | Bosch CHINAMFG and Parker |

| Coating | Sandblasting, primer, middle paint, finish paint |

| Temperature range | -40ºC to +300ºC |

| Work medium | Hydraulic Oil |

| Piston speed | maximum 2m/s |

| Mounting style | Earrings, flange, foot mounting, screw thread. |

Product Application

Company Show

HETLOCK is a professional manufacturer of hydraulic cylinders in China, Founded in 1998, located in the international city of ZheJiang . Our plant is nearly 20000 square meter& We have 135 Employees including 11 experienced engineers and technical staff,More than 1800 type of hydraulic cylinder designed in every year. We can produce various kinds of hydraulic cylinders according to customer requirements.

The inside diameter of hydraulic cylinders can achieve the maximum 2500mm;

The hydraulic cylinders operating pressure can achieve the maximum 300MPa.

FAQ

Q1:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q2: How many years of production experience do you have?

A: We have over 20 years of production experience.

Q3: Can it be customized?

A: Both standard and non-standard products can be customized.

Q4: How to ensure product quality?

A: We strictly follow the quality process for production and 100% inspection of each batch of products.

Q5: What services can you provide?

A: According to customer requirements, we can provide a one-stop solution from design, production, and delivery to meet their needs.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can telescopic cylinders be used in construction equipment like cranes?

Yes, telescopic cylinders are commonly used in construction equipment, including cranes. Here’s a detailed explanation:

Role in crane operation:

Telescopic cylinders play a critical role in the operation of cranes by enabling the extension and retraction of crane booms or arms. The telescopic cylinder is typically located at the base of the boom and is responsible for extending or retracting the boom sections, allowing the crane to reach different heights and distances.

Extension and retraction mechanism:

The telescopic cylinder in a crane consists of multiple stages or sleeves that retract inside one another. This nested design allows for compact storage when the boom is retracted, minimizing the overall length of the crane. When the cylinder extends, the stages slide out, increasing the length of the boom and providing the necessary reach. The synchronized extension and retraction of the stages are facilitated by the hydraulic control system.

Hydraulic control system:

The hydraulic control system in cranes is responsible for the precise and controlled extension and retraction of telescopic cylinders. It regulates the flow of hydraulic fluid to each stage of the cylinder, ensuring synchronized movement. By adjusting the flow rate, the operator can control the speed of extension and retraction, allowing for smooth and controlled operation of the crane.

Load handling capabilities:

Telescopic cylinders in cranes are designed to handle significant loads. They provide the necessary lifting force to support heavy loads at various boom lengths. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and to deliver the required lifting capacities.

Variety of crane types:

Telescopic cylinders are utilized in various types of cranes, including mobile cranes, truck-mounted cranes, and crawler cranes. These cranes are widely used in construction sites, infrastructure projects, and other lifting and material handling applications. The versatility of telescopic cylinders allows them to be integrated into different crane designs and configurations.

Advantages of telescopic cylinders in cranes:

Telescopic cylinders offer several advantages in crane applications. These include:

- Compactness: Telescopic cylinders enable the boom to be retracted to a compact size, making it easier to transport and maneuver the crane in confined spaces.

- Reach and height capabilities: The telescopic design allows the crane to achieve extended reach and height, enabling it to access elevated work areas or reach over obstacles.

- Efficiency: The controlled extension and retraction of telescopic cylinders contribute to efficient operation, allowing the crane to adjust its boom length quickly and precisely.

- Stability: Telescopic cylinders provide stability to the crane by supporting the boom and load, ensuring safe lifting and lowering of heavy objects.

Overall, telescopic cylinders are integral components of construction equipment like cranes. They enable the extension and retraction of crane booms, contribute to efficient and controlled operation, and enhance the lifting capabilities of cranes in various construction and material handling tasks.

It’s important to consult the crane manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

How do telescopic cylinders contribute to stable and safe equipment operation?

Telescopic cylinders play a significant role in ensuring stable and safe equipment operation. Here’s a detailed explanation:

Load distribution:

Telescopic cylinders assist in distributing the load evenly across the equipment. As the cylinders extend or retract, they provide support and help maintain the balance of the load. This load distribution is crucial for preventing equipment instability, reducing the risk of tipping or tilting, and ensuring safe operation.

Weight management:

Telescopic cylinders aid in managing the weight distribution of equipment during various operations. By extending or retracting the cylinders selectively, operators can control the positioning and center of gravity of the load. This helps mitigate the risk of equipment imbalance, enhances stability, and promotes safe equipment operation.

Controlled movements:

Telescopic cylinders enable controlled and precise movements of equipment components. The hydraulic control system regulates the extension and retraction of the cylinders, allowing operators to adjust the speed, force, and position of the movement. This precise control minimizes sudden or jerky motions, reduces the likelihood of equipment instability, and enhances overall safety during operation.

Shock absorption:

Telescopic cylinders provide a level of shock absorption during equipment operation. The design of the cylinders, along with the hydraulic system, helps absorb and dampen sudden shocks or impacts that may occur during material handling or terrain traversal. This shock absorption capability reduces stress on the equipment, minimizes the risk of component failure or damage, and contributes to safe and smooth operation.

Operator safety:

Telescopic cylinders contribute to operator safety by providing stability and control. The stable operation of equipment facilitated by the cylinders reduces the risk of accidents or operator injury caused by equipment instability, tipping, or excessive vibrations. Additionally, the precise control over equipment movements enhances operator confidence and minimizes the likelihood of human error during operation.

Monitoring and feedback:

Telescopic cylinders can be integrated with monitoring systems that provide real-time feedback on cylinder performance, load distribution, and equipment stability. This information allows operators to make informed decisions, take corrective actions if necessary, and ensure ongoing safe operation.

Overall, telescopic cylinders contribute to stable and safe equipment operation through load distribution, weight management, controlled movements, shock absorption, operator safety, and monitoring capabilities. Their role in maintaining equipment stability and providing precise control enhances operational safety and reduces the risk of accidents or equipment failure.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders to ensure safe equipment usage.

Can telescopic cylinders be customized for specific machinery and equipment?

Yes, telescopic cylinders can be customized to meet the specific requirements of different machinery and equipment. Here’s a detailed explanation:

Customizable stroke length:

Telescopic cylinders can be designed and manufactured with customized stroke lengths to suit the specific needs of machinery and equipment. The stroke length determines the maximum extension or retraction distance of the cylinder and can be tailored to match the required range of motion for a particular application.

Adjustable force and speed:

The hydraulic control system of telescopic cylinders allows for adjustability in terms of force and speed. The system can be configured to provide the necessary force output for the machinery or equipment, ensuring optimal performance. Additionally, the speed of extension and retraction can be adjusted to match the operational requirements, enabling precise and efficient operation.

Mounting options:

Telescopic cylinders can be customized with different mounting options to facilitate easy integration with specific machinery and equipment. Mounting configurations can vary depending on factors such as available space, mounting orientation, and compatibility with existing systems. Manufacturers can provide various mounting solutions to ensure seamless installation.

Sealing and protection:

In certain applications, telescopic cylinders may require specialized sealing and protection features. Manufacturers can customize the cylinder design to incorporate seals and protective coatings that are suitable for the working environment. This customization helps enhance the longevity and reliability of the cylinder, especially in harsh operating conditions.

Material selection:

Telescopic cylinders can be manufactured using different materials to meet specific machinery and equipment requirements. Material selection depends on factors such as load capacity, operating temperature, corrosion resistance, and weight considerations. Manufacturers can offer material options to ensure the cylinder’s compatibility and performance in the intended application.

Integration with control systems:

Telescopic cylinders can be integrated with control systems and sensors to enable advanced functionality and automation. Customization may involve incorporating position sensors, pressure sensors, or other feedback devices to provide real-time data and enhance the overall performance and safety of the machinery or equipment.

Overall, telescopic cylinders can be customized in terms of stroke length, force and speed adjustability, mounting options, sealing and protection features, material selection, and integration with control systems. This customization allows telescopic cylinders to be tailored to the specific requirements of machinery and equipment, ensuring optimal performance and functionality.

It’s important to collaborate with the manufacturer or a qualified expert to determine the appropriate customization options and ensure compliance with relevant industry standards and regulations.

<img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l1.webp" alt="China Professional Large Bore Hydraulic Piston 2 Stage Telescopic Double Acting Cylinder vacuum pump ac”><img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l2.webp" alt="China Professional Large Bore Hydraulic Piston 2 Stage Telescopic Double Acting Cylinder vacuum pump ac”>

editor by Dream 2024-10-08

China Standard Manufacturer Factory Custom Large High Pressure Single Double Acting Telescopic Piston Hydraulic Press Cylinder with Best Sales

Product Description

Product Description

Hydraulic press cylinder:

Hetlock(ZheJiang )Machinery Co.,Ltd. is familiar with the all kinds of hydraulic press machine working condition.

Due to the hydraulic cylinder long-term work under high pressure and short-term impact pressure, have highly requirements of holding pressure performance, So, for the selection of sealing form, The design of buffer structure, The strength of all the part of hydraulic cylinder, and highly requirements of Welding performance.

We have the professional calculation software for checking the strength of each part. To ensure the hydraulic cylinder service life time and reliability.

Our products have applications in:

- Steel industry press;

- Hydro forming press;

- Automotive industry press;

- Plastic or rubber industry press;

- Deep drawing press;

- Molding press;

- Multi purpose press;

- Blanking press;

- Recycling industry press;

- Stamping press;

- Etc.

Product Parameters

| Material | Carbon steel, Alloy steel, Stainless steel |

| Honed tube | 20-2500mm, Heat treatment, honing, rolling |

| Piston rod | 10-2000mm ,tempering, plated nickel, Chromium or ceramic |

| Working Pressure | 5-300Mpa |

| Seals | Parker,Merkel,Hallite |

| Technology | Bosch CHINAMFG and Parker |

| Coating | Sandblasting, primer, middle paint, finish paint |

| Temperature range | -40ºC to +300ºC |

| Work medium | Hydraulic Oil |

| Piston speed | maximum 2m/s |

| Mounting style | Earrings, flange, foot mounting, screw thread. |

Product Application

Company Show

HETLOCK is a professional manufacturer of hydraulic cylinders in China, Founded in 1998, located in the international city of ZheJiang . Our plant is nearly 20000 square meter& We have 135 Employees including 11 experienced engineers and technical staff,More than 1800 type of hydraulic cylinder designed in every year. We can produce various kinds of hydraulic cylinders according to customer requirements.

The inside diameter of hydraulic cylinders can achieve the maximum 2500mm;

The hydraulic cylinders operating pressure can achieve the maximum 300MPa.

FAQ

Q1:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q2: How many years of production experience do you have?

A: We have over 20 years of production experience.

Q3: Can it be customized?

A: Both standard and non-standard products can be customized.

Q4: How to ensure product quality?

A: We strictly follow the quality process for production and 100% inspection of each batch of products.

Q5: What services can you provide?

A: According to customer requirements, we can provide a one-stop solution from design, production, and delivery to meet their needs.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can hydraulic cylinders be used for precise operations like CNC machining or molding?

Yes, hydraulic cylinders can be used for precise operations like CNC machining or molding. While hydraulic systems are commonly associated with heavy-duty applications, they can also provide the necessary precision and control required for precise operations in CNC machining and molding processes. Here’s a detailed explanation of how hydraulic cylinders can be utilized for such precise operations:

1. Force and Control:

– Hydraulic cylinders are capable of generating substantial force, which is essential for precise operations in CNC machining and molding. By using hydraulic pressure, the cylinders can deliver the required force to cut or shape materials accurately or exert pressure for molding operations. The hydraulic system allows precise control over the force applied, ensuring consistent and reliable performance.

2. Adjustable Speed and Positioning:

– Hydraulic cylinders offer adjustable speed and precise positioning capabilities, making them suitable for precise operations. By controlling the flow of hydraulic fluid, the speed of the cylinder’s movement can be adjusted according to specific requirements. This adaptability allows for fine-tuning the machining or molding process, achieving the desired precision in material removal or shaping. Hydraulic systems also enable accurate positioning of tools or molds, ensuring precise operations.

3. Integrated Feedback Systems:

– Advanced hydraulic systems can incorporate feedback sensors and control mechanisms to enhance precision in CNC machining and molding. These sensors provide real-time information about the position, speed, and force exerted by the hydraulic cylinders. The control system processes this data and adjusts the flow of hydraulic fluid accordingly, allowing for precise and accurate control over the operations. The feedback systems help maintain consistent performance and compensate for any deviations, ensuring high precision.

4. Damping and Vibration Control:

– Hydraulic cylinders can be equipped with damping mechanisms to minimize vibrations and ensure stability during CNC machining or molding operations. Vibrations can negatively impact precision by causing tool chatter or material deformation. By incorporating cushioning or damping features, hydraulic cylinders help absorb shocks and suppress vibrations, resulting in smoother and more accurate operations.

5. Customization and Adaptability:

– Hydraulic cylinders can be customized and adapted to meet the specific requirements of CNC machining or molding processes. Engineers can design cylinders with unique dimensions, stroke lengths, mounting options, and sealing arrangements to fit into equipment or systems with precise specifications. Customized hydraulic cylinders ensure optimal performance and compatibility for precise operations, enabling seamless integration into CNC machines or molding equipment.

6. Energy Efficiency:

– Hydraulic systems can be designed to be energy-efficient, contributing to cost savings in CNC machining or molding operations. By utilizing variable speed pumps, efficient control valves, and well-designed hydraulic circuits, energy consumption can be optimized. This efficiency reduces heat generation, leading to improved stability and precision in operations while minimizing energy costs.

7. Maintenance and Calibration:

– Regular maintenance and calibration of hydraulic systems are essential to maintain their precision in CNC machining or molding applications. Proper lubrication, inspection of seals, and replacement of worn-out components help ensure optimal performance. Regular calibration of control systems and feedback sensors ensures accurate readings and reliable operation, contributing to precision in machining or molding processes.

In summary, hydraulic cylinders can be effectively used for precise operations like CNC machining or molding. Their ability to generate substantial force, adjustable speed and positioning, integration with feedback systems, damping and vibration control, customization and adaptability, energy efficiency, and proper maintenance contribute to achieving the required precision in these operations. By leveraging the strengths of hydraulic systems, manufacturers can enhance the accuracy and reliability of CNC machining or molding processes, resulting in high-quality products and improved productivity.

Handling Challenges of Different Fluid Viscosities in Hydraulic Cylinders

Hydraulic cylinders are designed to handle the challenges associated with different fluid viscosities. The viscosity of hydraulic fluid can vary based on temperature, type of fluid used, and other factors. Hydraulic systems need to accommodate these variations to ensure optimal performance and efficiency. Let’s explore how hydraulic cylinders handle the challenges of different fluid viscosities:

- Fluid Selection: Hydraulic cylinders are designed to work with a range of hydraulic fluids, each with its specific viscosity characteristics. The selection of an appropriate fluid with the desired viscosity is crucial to ensure optimal performance. Manufacturers provide guidelines regarding the recommended viscosity range for specific hydraulic systems and cylinders. By choosing the right fluid, hydraulic cylinders can effectively handle the challenges posed by different fluid viscosities.

- Viscosity Compensation: Hydraulic systems often incorporate features to compensate for variations in fluid viscosity. For example, some hydraulic systems utilize pressure compensating valves that adjust the flow rate based on the viscosity of the fluid. This compensation ensures consistent performance across different operating conditions and fluid viscosities. Hydraulic cylinders work in conjunction with these compensation mechanisms to maintain precision and control, regardless of the fluid viscosity.

- Temperature Control: Fluid viscosity is highly dependent on temperature. Hydraulic cylinders employ various temperature control mechanisms to address the challenges posed by temperature-induced viscosity changes. Heat exchangers, coolers, and thermostatic valves are commonly used to regulate the temperature of the hydraulic fluid within the system. By controlling the fluid temperature, hydraulic cylinders can maintain the desired viscosity range, ensuring reliable and efficient operation.

- Efficient Filtration: Contaminants in hydraulic fluid can affect its viscosity and overall performance. Hydraulic systems incorporate efficient filtration systems to remove particles and impurities from the fluid. Clean fluid with the appropriate viscosity ensures optimal functioning of hydraulic cylinders. Regular maintenance and filter replacements are essential to uphold the desired fluid viscosity and prevent issues related to fluid contamination.

- Proper Lubrication: Different fluid viscosities can impact the lubrication properties within hydraulic cylinders. Lubrication is essential for minimizing friction and wear between moving parts. Hydraulic systems employ lubricants specifically formulated for the anticipated fluid viscosity range. Adequate lubrication ensures smooth operation and extends the lifespan of hydraulic cylinders, even in the presence of varying fluid viscosities.

In summary, hydraulic cylinders employ various strategies to handle the challenges associated with different fluid viscosities. By selecting appropriate fluids, incorporating viscosity compensation mechanisms, controlling temperature, implementing efficient filtration, and ensuring proper lubrication, hydraulic cylinders can accommodate variations in fluid viscosity. These measures enable hydraulic systems to deliver consistent performance, precise control, and efficient operation across different fluid viscosity ranges.

What benefits do hydraulic cylinders offer for tasks requiring heavy lifting or movement?

Hydraulic cylinders offer numerous benefits for tasks that involve heavy lifting or movement. Their unique design and characteristics make them well-suited for applications that require substantial force, precise control, and reliable operation. Here are the detailed benefits that hydraulic cylinders provide for such tasks:

1. High Force Generation:

– Hydraulic cylinders are capable of generating significant amounts of force. By utilizing hydraulic pressure, which can be easily amplified, hydraulic cylinders can exert substantial force to lift and move heavy loads. The force output of a hydraulic cylinder is directly proportional to the hydraulic pressure and the surface area of the piston. This high force capability makes hydraulic cylinders ideal for tasks that involve heavy lifting, pushing, or pulling.

2. Precise Control:

– Hydraulic cylinders offer precise control over the force and motion they generate. By regulating the flow of hydraulic fluid into the cylinder, the speed, direction, and position of the cylinder’s movement can be accurately controlled. This level of control is crucial for tasks that require precise positioning, delicate movements, or synchronization of multiple cylinders. It enables operators to perform operations with accuracy and minimize the risk of damage or accidents.

3. Safety:

– Hydraulic cylinders are designed with safety features to ensure the protection of both personnel and equipment. They incorporate overload protection mechanisms, such as relief valves, that prevent excessive force or pressure from damaging the system. Additionally, hydraulic cylinders allow for controlled and gradual movements, reducing the risk of sudden and uncontrolled motions that could pose safety hazards during heavy lifting or movement tasks.

4. Versatility and Adaptability:

– Hydraulic cylinders are versatile components that can be adapted to meet specific requirements. They can be customized based on factors such as force capacity, stroke length, speed, and mounting options, allowing them to be integrated into various types of machinery. This versatility makes hydraulic cylinders suitable for a wide range of applications, including construction, material handling, mining, agriculture, and more.