Product Description

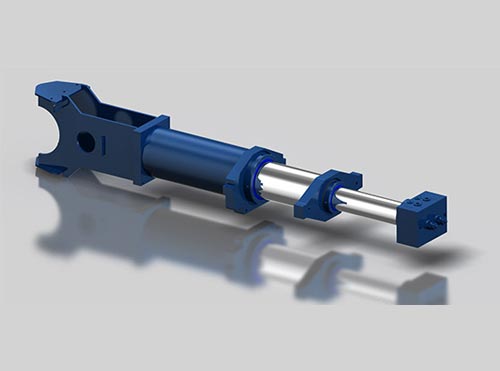

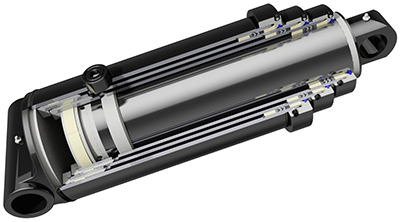

single-acting/double-acting telescopic hydraulic cylinder for CAT excavator

Product Description:

Widely used in equipment for Engineering, Coal&mine, Agriculture and Environmental sanitation

single-acting/double-acting telescopic hydraulic cylinder for CAT excavator used in engineering has high requirements for security performance, as it works frequently with large shock and vibration, so the requirements of reliability is high. Limit working condition bear large lateral load, so it has higher requirements for hardness and wear resistance.

Product Display:

Specifications:

| Item | Specifications |

| Product Name | single-acting/double-acting telescopic hydraulic cylinder for CAT excavator |

| Certificate: | CE, ISO9001 |

| Packaging | metal case;plywood case;carton or as requirement |

| MOQ | According to products |

| Brand | GLIT or customer’s logo |

| Service | OEM & ODM |

| Piston Rod | Chrome or nickel plated,ground & polished piston rod |

| Seal Type | Parker,NOK, Hallite or as customer’s requirement |

| Tube | High tensile cold drawn tube, precision honed for extended seal life |

| Delivery Time | Based on order quantity. normally 15-30 days. |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer & Exporter |

Mounting Method:

Our Factory:

Inspection Process:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Packing & Delivery:

Appliactions:

Application: Mobile Cranes, Trailer, excavator, log splitter, hydraulic press, garbage compactor,

lift platform, dock leveler

About US:

HangZhou GLORIA INDUSTRIAL TECH Co., Ltd. is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, CHINAMFG provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, GLIT can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 20-30 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 40% when order is confirmed and 60% before shipment. L/C is also acceptable for amount over 20,000USD.

9, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Structure: | Piston Type |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can telescopic cylinders be repaired or maintained when necessary?

Yes, telescopic cylinders can be repaired and maintained when necessary. Here’s a detailed explanation:

Repairability:

Telescopic cylinders are designed with repairability in mind. The modular construction of telescopic cylinders allows for individual components or stages to be replaced or repaired as needed. If a specific part of the cylinder becomes damaged or worn out, it can be disassembled and repaired or replaced, minimizing downtime and cost compared to replacing the entire cylinder.

Maintenance:

Maintenance is essential to ensure the optimal performance and longevity of telescopic cylinders. Regular maintenance practices may include:

- Inspection: Periodic visual inspections to check for any signs of damage, wear, or leakage.

- Lubrication: Applying lubricants to the moving parts of the cylinder to reduce friction and extend component life.

- Cleaning: Removing dirt, debris, and contaminants that may affect the cylinder’s operation.

- Seal replacement: Replacing worn or damaged seals to maintain proper sealing and prevent fluid leakage.

- Pressure testing: Conducting pressure tests to ensure the cylinder’s integrity and identify any potential issues.

- Alignment and adjustment: Verifying proper alignment and making necessary adjustments to ensure smooth operation and prevent excessive wear.

Depending on the specific application and operating conditions, maintenance intervals and procedures may vary. It’s important to follow the manufacturer’s maintenance recommendations and guidelines for the telescopic cylinder to ensure effective maintenance practices.

Professional expertise:

Repairing and maintaining telescopic cylinders often require professional expertise. It is recommended to engage qualified technicians or service personnel with experience in hydraulic systems and telescopic cylinder repairs. They have the knowledge and tools necessary to accurately diagnose issues, perform repairs, and conduct maintenance tasks in a safe and efficient manner.

Manufacturer support:

Manufacturers of telescopic cylinders typically provide support for repair and maintenance. They may offer technical documentation, repair manuals, and access to replacement parts to facilitate the repair process. Consulting the manufacturer’s resources and seeking their assistance can ensure that repairs and maintenance are carried out correctly and in accordance with the cylinder’s specifications.

By implementing proper repair and maintenance practices, telescopic cylinders can be kept in good working condition, extending their service life and maintaining reliable performance.

It’s important to note that repair and maintenance should be performed by qualified individuals and comply with relevant safety guidelines and industry standards.

How do telescopic cylinders contribute to precise reach and manipulation?

Telescopic cylinders play a crucial role in enabling precise reach and manipulation in various applications. Here’s a detailed explanation:

Extended reach:

Telescopic cylinders allow for extended reach in equipment such as cranes, excavators, booms, and material handling machinery. The nested design of telescopic cylinders, with multiple stages that retract inside one another, enables the equipment to achieve a longer reach when required. By extending the telescopic cylinder, operators can access objects or work areas that are located at a distance.

Precise positioning:

Telescopic cylinders provide precise positioning capabilities, allowing operators to manipulate objects with accuracy. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, enabling smooth and controlled movement. This precise control is essential in applications that require accurate placement or manipulation of objects, such as in construction, manufacturing, or material handling.

Load handling:

Telescopic cylinders contribute to precise load handling by providing the necessary force and control. The cylinders are designed to handle heavy loads and can exert the required power to lift, lower, or manipulate objects with precision. The hydraulic control system allows operators to adjust the speed and movement of the telescopic cylinder, ensuring safe and controlled load handling.

Adaptability:

Telescopic cylinders offer adaptability in reaching and manipulating objects in various environments. Their nested design allows for compact retraction, making them suitable for applications with limited space. The ability to extend and retract the telescopic cylinder provides flexibility in adjusting the reach and adapting to different working conditions.

Support for attachments:

Telescopic cylinders often support attachments or tools that enhance reach and manipulation capabilities. For example, in excavators, telescopic cylinders are used to extend the boom or arm, while additional attachments such as buckets or grabs facilitate precise material handling or excavation tasks.

Overall, telescopic cylinders contribute to precise reach and manipulation by offering extended reach, precise positioning, load handling capabilities, adaptability, and support for attachments. Their hydraulic control system and nested design enable operators to achieve accurate and controlled movements, enhancing productivity and efficiency in various applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, operating parameters, and recommended maintenance practices to ensure optimal performance and safety.

How does a telescopic cylinder differ from standard hydraulic cylinders?

A telescopic cylinder differs from standard hydraulic cylinders in several ways. Here’s a detailed explanation:

A telescopic cylinder, also known as a multistage cylinder or a sleeve cylinder, is specifically designed to provide an extended stroke length while maintaining a compact retracted length. In contrast, a standard hydraulic cylinder typically consists of a single-stage rod and barrel design. Here are the key differences between a telescopic cylinder and a standard hydraulic cylinder:

- Design and Structure: The most significant difference lies in the design and structure. A standard hydraulic cylinder has a single-stage design, meaning it consists of a single rod and barrel. On the other hand, a telescopic cylinder features multiple stages or sleeves nested inside one another. This nested structure allows for a longer stroke length while keeping the retracted length compact.

- Stroke Length: The stroke length of a telescopic cylinder can be significantly longer compared to a standard hydraulic cylinder. The ability to extend in multiple stages allows for a greater overall stroke length, making telescopic cylinders suitable for applications that require extended reach or height adjustment.

- Retracted Length: While a standard hydraulic cylinder has a fixed retracted length equal to its stroke length, a telescopic cylinder offers a compact retracted length. The nested design enables the stages to retract inside one another, reducing the overall length of the cylinder when not in use. This compact retracted length is advantageous in applications with space constraints.

- Load Capacity: Telescopic cylinders are designed to handle substantial loads while maintaining stability. The nested structure provides increased load-bearing capacity compared to standard hydraulic cylinders. The stages distribute the load evenly, ensuring efficient load transfer throughout the extended stroke.

- Complexity and Maintenance: Telescopic cylinders are generally more complex in design compared to standard hydraulic cylinders. They require precise alignment of the stages and may include additional components such as locking mechanisms or guiding systems. This complexity can affect maintenance requirements and may require specialized inspection and servicing procedures.

- Application: Telescopic cylinders are commonly used in applications that require extended reach or height adjustment, such as cranes, dump trucks, aerial platforms, and material handling equipment. Standard hydraulic cylinders, on the other hand, are versatile and widely used in various applications, including industrial machinery, construction equipment, and agricultural machinery.

Despite these differences, both telescopic cylinders and standard hydraulic cylinders are essential components in hydraulic systems. They both rely on hydraulic fluid to generate force and provide linear motion. The selection of the cylinder type depends on the specific requirements of the application, including stroke length, retracted length, load capacity, and available space.

It’s important to consult the manufacturer’s guidelines and specifications to ensure the proper selection, installation, and maintenance of the hydraulic cylinder based on the specific application requirements.

editor by CX 2024-02-25