Product Description

Mining Dump Truck Spare Parts Multistage Telescopic Single Acting Lift Hydraulic Cylinder Made in China

Product Specifications :

| Item | Specifications |

| Function | Lifting/lowering the truck body for cargo dumping |

| Bore diameter | 120mm-480mm,customizable |

| Bod diameter | 90mm-390mm,customizable |

| Stroke | 3000mm-12000mm,customizable |

| Stage | 2-6stages,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,customizable |

| Seal Type | Parker,NOK, Hallite or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Packaging | metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

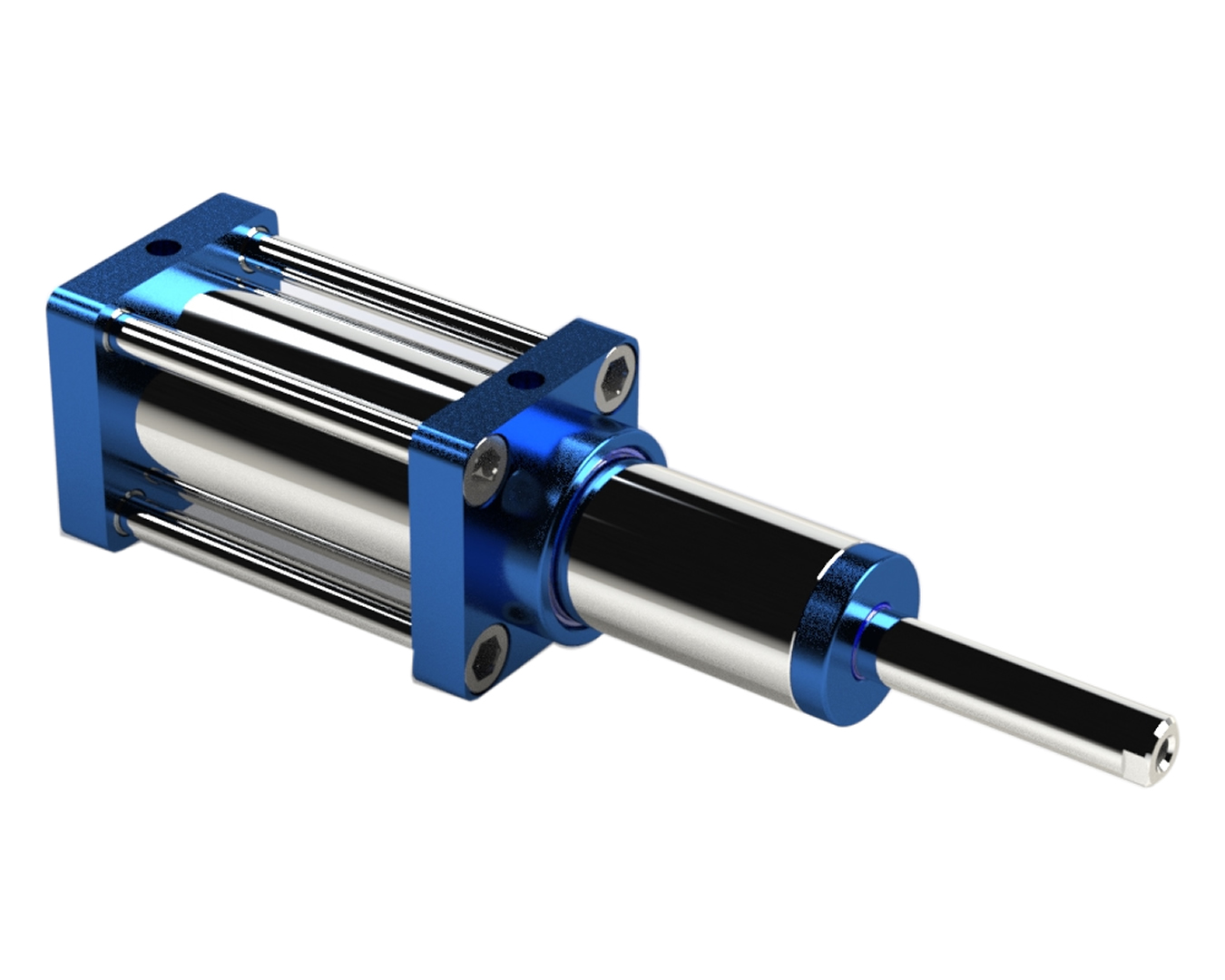

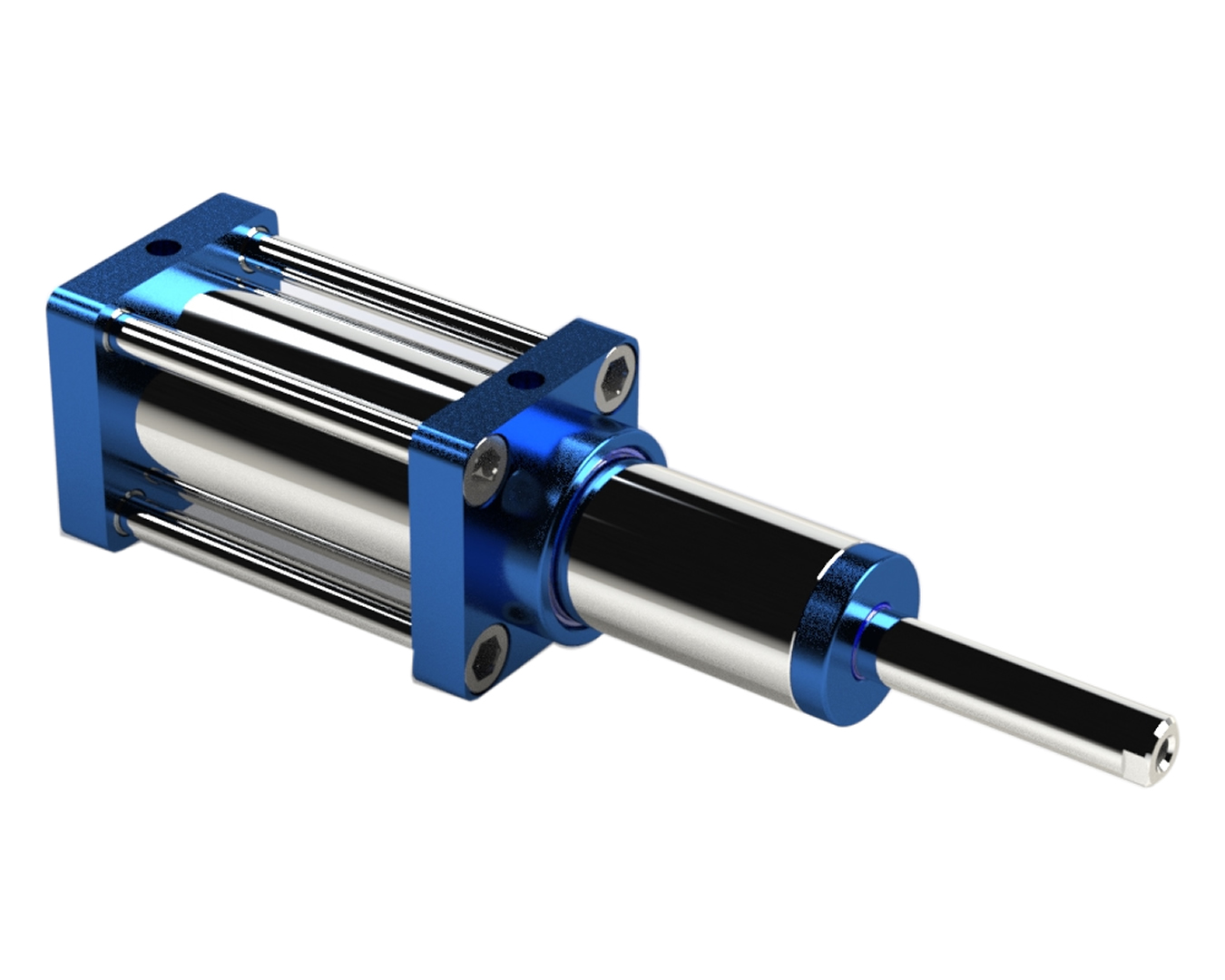

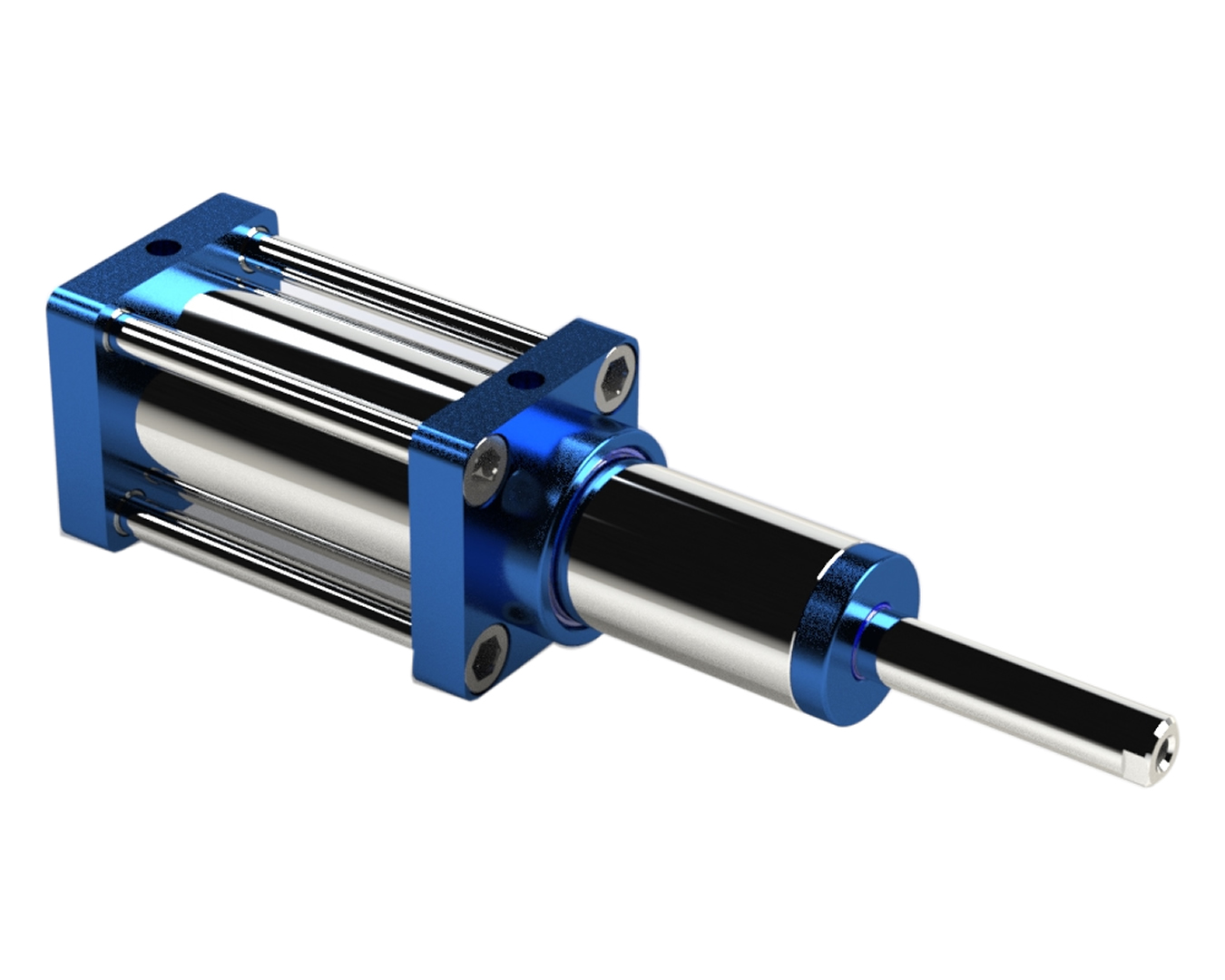

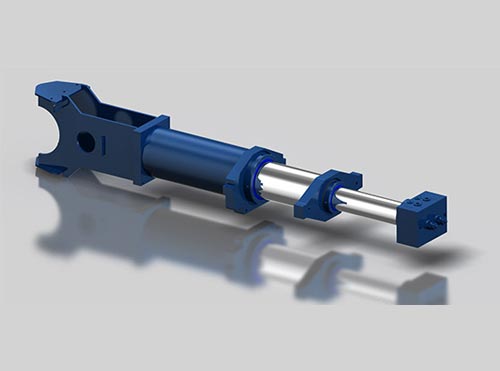

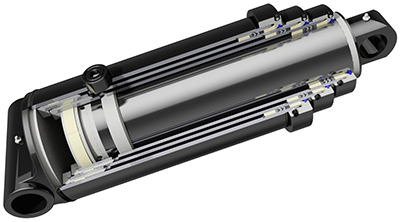

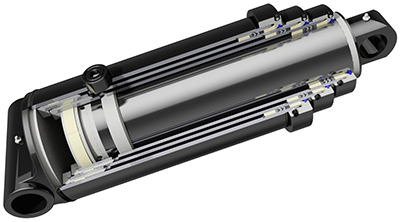

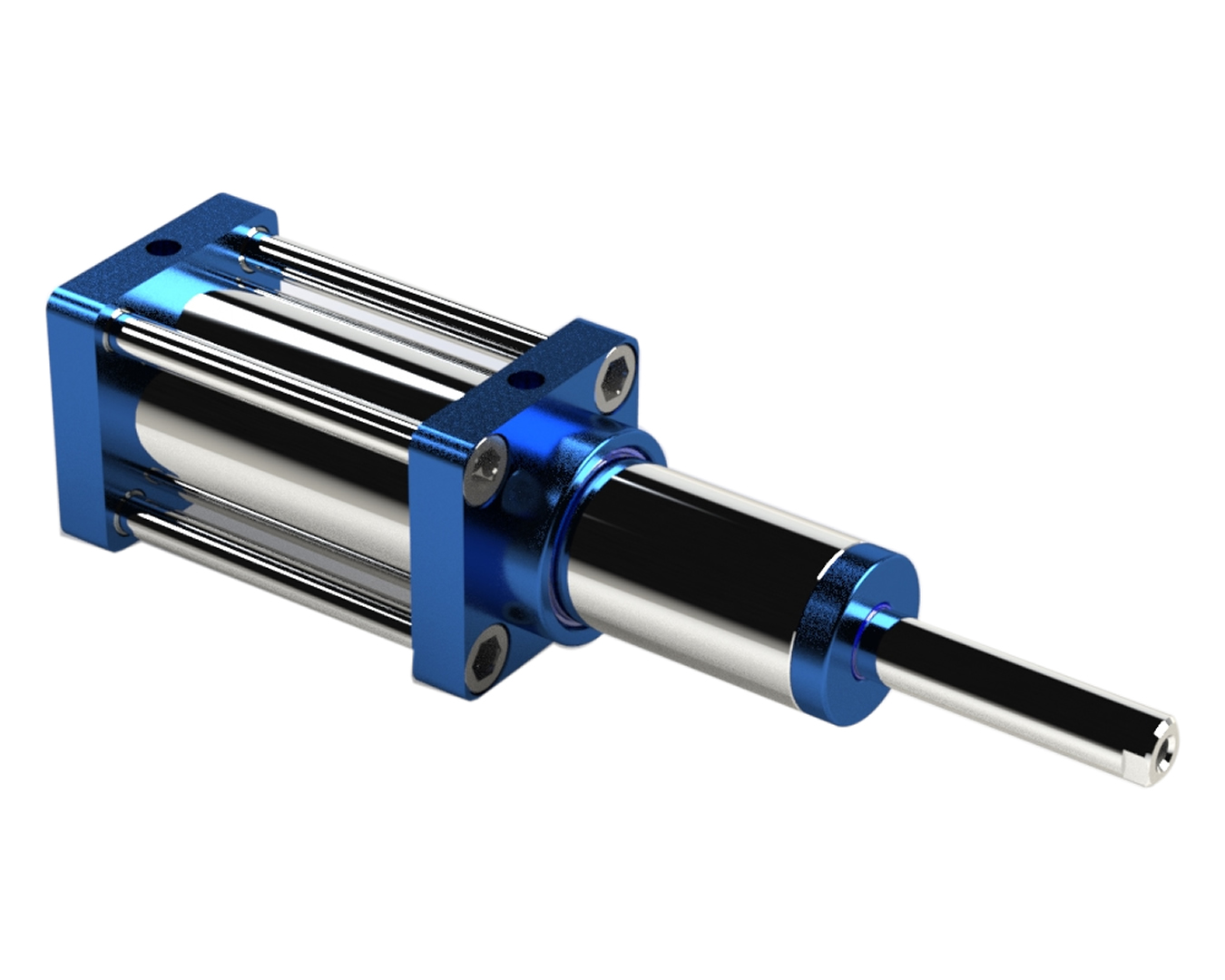

Product Display:

Mounting Method:

Appliactions:Mining Machinery,Mining Dump Truck

Other Related Products

Our Factory:

Quality Assurance:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection of Mechanical Properties of Raw Materials

Process Inspection

Final Testing

Packing & Delivery:

About US:

Our Certificate

Our Main Customers

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 600/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do telescopic cylinders handle variations in load capacity and weight?

Telescopic cylinders are designed to handle variations in load capacity and weight effectively. Here’s a detailed explanation:

Load-specific design:

Telescopic cylinders are engineered with load-specific design considerations to accommodate variations in load capacity and weight. Manufacturers take into account factors such as the maximum expected load, the range of anticipated loads, and the required safety factors. The cylinder’s components, materials, and dimensions are selected and configured accordingly to provide the necessary strength and stability.

Multiple stages:

The nested structure of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for adaptability to different loads. Each stage can handle a specific portion of the load, and the collective capacity of all stages determines the overall load capacity of the cylinder. By adding or removing stages, telescopic cylinders can be customized to suit different load requirements, providing flexibility in handling variations in weight.

Hydraulic system control:

The hydraulic control system of telescopic cylinders plays a vital role in managing variations in load capacity. By regulating the flow of hydraulic fluid to each stage, operators can control the extension and retraction force applied to the cylinder. This control allows for adjustments based on the specific load and weight requirements, ensuring the cylinder operates within its safe working limits.

Pressure relief and overload protection:

Telescopic cylinders are often equipped with pressure relief valves and overload protection mechanisms to safeguard against excessive loads. Pressure relief valves help prevent over-pressurization of the hydraulic system by diverting excess fluid flow, protecting the cylinder from potential damage. Overload protection mechanisms, such as overload sensors or mechanical stops, are designed to activate and halt the cylinder’s movement if the load exceeds the safe operating limits.

Load distribution and stability:

Telescopic cylinders contribute to load distribution and stability. The nested design distributes the load across multiple stages, reducing stress on individual components and enhancing overall stability. Proper weight distribution on the machinery or equipment, as well as secure attachment of the load, further contribute to maintaining stability and ensuring safe operation.

It’s important to note that while telescopic cylinders can handle variations in load capacity and weight, it is crucial to operate within the specified load limits and follow the manufacturer’s guidelines. Exceeding the recommended load capacity can compromise the safety, performance, and longevity of the telescopic cylinder and the machinery it is installed on.

Consulting the manufacturer’s documentation, engineering specifications, and relevant industry standards is essential for understanding and adhering to the appropriate load capacity and weight guidelines when using telescopic cylinders.

How do telescopic cylinders handle variations in cylinder size and capacity?

Telescopic cylinders are designed to handle variations in cylinder size and capacity effectively. Here’s a detailed explanation:

Modular design:

Telescopic cylinders feature a modular design that allows for flexibility in cylinder size and capacity. They consist of multiple stages or sections that retract inside one another, similar to a telescope. The number of stages can vary depending on the desired extended length and capacity of the cylinder. This modular design enables telescopic cylinders to be customized according to specific requirements.

Variable stroke length:

Telescopic cylinders offer the advantage of variable stroke length. The stroke length refers to the distance the cylinder can extend and retract. By adjusting the stroke length, the effective size and capacity of the telescopic cylinder can be modified. This flexibility allows for accommodating variations in the size and capacity requirements of different applications.

Increased capacity with additional stages:

Telescopic cylinders can handle variations in capacity by adding more stages to the cylinder. Each stage contributes to the overall capacity of the cylinder. By including additional stages, the cylinder’s capacity can be increased to handle higher loads or operate in more demanding conditions. This scalability makes telescopic cylinders suitable for a wide range of applications with varying capacity needs.

Proportional force distribution:

Telescopic cylinders distribute the applied force proportionally across the stages. As the cylinder extends, each stage contributes to supporting the load and transmitting the force. The force distribution ensures that the load is evenly distributed among the stages, allowing the cylinder to handle variations in capacity effectively.

Hydraulic control system:

Telescopic cylinders rely on a hydraulic control system for operation. The system allows for precise control over the extension and retraction of each stage. By adjusting the hydraulic pressure and flow, operators can regulate the movement and force exerted by the cylinder, ensuring optimal performance and capacity utilization.

Overall, telescopic cylinders handle variations in cylinder size and capacity through their modular design, variable stroke length, ability to add stages for increased capacity, proportional force distribution, and hydraulic control system. These features make telescopic cylinders adaptable to different applications and enable them to effectively handle varying size and capacity requirements.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the size, capacity, and operational considerations of telescopic cylinders.

Can you explain the purpose and role of telescopic cylinders in machinery?

Telescopic cylinders play a crucial role in various machinery and equipment applications. Here’s a detailed explanation:

Purpose of telescopic cylinders:

Telescopic cylinders are primarily used when an extended stroke length is required while maintaining a compact retracted length. They enable machinery and equipment to achieve extended reach, height adjustment, or lifting capabilities without increasing the overall size or footprint of the cylinder. The purpose of telescopic cylinders is to provide efficient and reliable linear motion in applications that demand long stroke lengths.

Role of telescopic cylinders in machinery:

- Material Handling: Telescopic cylinders are extensively used in material handling machinery, such as cranes, forklifts, and loaders. They enable the extension and retraction of booms, arms, or lifting mechanisms, allowing operators to reach higher or farther to handle and transport materials with ease.

- Dump Trucks and Trailers: Telescopic cylinders are commonly employed in dump trucks and trailers for the tilting and unloading of cargo or bulk materials. The extendable stroke of the cylinder raises the bed or container to dump the contents, enabling efficient unloading and reducing manual labor.

- Aerial Platforms: Telescopic cylinders are essential components in aerial work platforms, such as cherry pickers or scissor lifts. They facilitate the vertical movement and height adjustment of the platform, allowing operators to access elevated work areas safely.

- Construction Equipment: Telescopic cylinders are used in various construction equipment, including excavators, backhoes, and telescopic handlers. They provide the necessary extension and retraction for the boom, arm, or bucket, enabling digging, lifting, and reaching capabilities in construction and earthmoving applications.

- Mobile Equipment: Telescopic cylinders are utilized in mobile equipment, such as telescopic cranes and mobile cranes. They enable the extension and retraction of the boom sections, allowing for increased reach and lifting capacities in lifting and construction operations.

- Specialized Machinery: Telescopic cylinders find application in specialized machinery, such as fire truck aerial ladders, telescopic masts, or telescopic booms in industrial and military equipment. They provide the required extension and retraction for specific tasks, such as firefighting, surveillance, or equipment deployment.

The role of telescopic cylinders in machinery is to provide precise and controlled linear motion, enabling the equipment to perform specific tasks with extended reach, height adjustment, or lifting capabilities. They contribute to the efficiency, versatility, and productivity of machinery in various industries.

It’s important to ensure proper selection, installation, and maintenance of telescopic cylinders based on the specific machinery requirements and manufacturer’s guidelines to ensure safe and reliable operation.

editor by CX 2023-12-27

China high quality Rod Piston Stroke Long Stroke Telescopic Hydraulic Cylinder for Mining Dump Truck vacuum pump distributors

Product Description

Rod Piston Stroke Long Stroke Telescopic Hydraulic Cylinder for Mining Dump Truck

Product Specifications :

| Item | Specifications |

| Function | Lifting/lowering the truck body for cargo dumping |

| Bore diameter | 120mm-480mm,customizable |

| Bod diameter | 90mm-390mm,customizable |

| Stroke | 3000mm-12000mm,customizable |

| Stage | 2-6stages,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,customizable |

| Seal Type | Parker,NOK, Hallite or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Packaging | metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Product Display:

Mounting Method:

Appliactions:Mining Machinery,Mining Dump Truck

Other Related Products

Our Factory:

Quality Assurance:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection of Mechanical Properties of Raw Materials

Process Inspection

Final Testing

Packing & Delivery:

About US:

Our Certificate

Our Main Customers

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 600/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do telescopic cylinders contribute to energy-efficient equipment operation?

Telescopic cylinders play a significant role in promoting energy-efficient equipment operation. Here’s a detailed explanation:

Reduced energy consumption:

Telescopic cylinders are designed to minimize energy consumption during equipment operation. The hydraulic system of telescopic cylinders allows for precise control over the extension and retraction of the cylinder stages. This control enables the equipment to use the minimum amount of hydraulic fluid and energy required to achieve the desired movement or position.

Efficient force transmission:

Telescopic cylinders are engineered to efficiently transmit forces from the hydraulic system to the desired application. The telescopic design allows for a direct and linear transfer of force, reducing energy losses that can occur in more complex mechanical systems. This efficient force transmission ensures that the energy supplied to the telescopic cylinder is effectively utilized to perform the desired work.

Compactness and weight reduction:

Telescopic cylinders offer compactness in equipment design, which contributes to energy efficiency. By retracting the cylinder stages, the overall length of the equipment can be minimized, reducing weight and inertia. This reduction in weight and inertia requires less energy to start and stop the movement of the equipment, resulting in energy savings during operation.

Optimized design:

Telescopic cylinders are designed with efficiency in mind. Manufacturers consider factors such as the cylinder’s bore size, rod diameter, and overall construction to ensure optimal performance while minimizing energy requirements. By using lightweight and high-strength materials, optimizing the cylinder’s dimensions, and reducing internal friction, telescopic cylinders can operate efficiently and contribute to energy savings.

Controlled motion:

Telescopic cylinders provide precise and controlled motion, allowing equipment operators to perform tasks with accuracy and efficiency. The hydraulic control system in telescopic cylinders enables smooth and proportional extension and retraction, reducing the need for excessive force or multiple adjustments. This controlled motion prevents energy waste and ensures that the equipment operates efficiently.

Applications in energy-efficient equipment:

Telescopic cylinders are utilized in various energy-efficient equipment, such as hybrid or electric-powered machinery. These equipment types rely on the optimization of energy usage to minimize environmental impact and reduce operating costs. Telescopic cylinders contribute to these objectives by providing efficient force transmission, controlled motion, and compact design.

Furthermore, the integration of advanced technologies, such as electronic control systems, sensors, and feedback mechanisms, can enhance the energy efficiency of equipment that incorporates telescopic cylinders. These technologies allow for further optimization of hydraulic system performance, energy recovery, and intelligent control of equipment operations.

Overall, telescopic cylinders contribute to energy-efficient equipment operation through reduced energy consumption, efficient force transmission, compactness and weight reduction, optimized design, and controlled motion. By utilizing telescopic cylinders in equipment design and considering energy-efficient practices, industries can achieve more sustainable and economical operation.

Consulting with equipment manufacturers or industry experts can provide further insights into the energy-saving benefits and applications of telescopic cylinders in specific equipment types.

Can telescopic cylinders be used in agricultural machinery for various tasks?

Yes, telescopic cylinders are widely used in agricultural machinery for various tasks. Here’s a detailed explanation:

Versatile applications:

Telescopic cylinders offer versatility and are suitable for a wide range of tasks in agricultural machinery. They are commonly employed in equipment such as tractors, harvesters, sprayers, loaders, and tillers.

Lifting and lowering:

Telescopic cylinders are utilized for lifting and lowering applications in agricultural machinery. They provide the necessary force to raise and lower attachments such as loader buckets, tillage implements, or harvest platforms. The telescopic cylinder’s design allows for efficient force transmission, enabling smooth and controlled movement.

Reach extension:

Telescopic cylinders are valuable for extending the reach of agricultural machinery. For example, in a harvester, telescopic cylinders can extend the reach of the harvesting arm, allowing operators to access crops in a broader area. This extension capability increases efficiency and productivity by reducing the need for repositioning the machinery frequently.

Adjustable working height:

Telescopic cylinders are employed in agricultural machinery to provide adjustable working heights. For instance, in sprayers or spreaders, telescopic cylinders can adjust the height of the booms or spreading mechanisms, allowing for precise application of fertilizers, pesticides, or seeds.

Folding and unfolding:

Telescopic cylinders are used to facilitate folding and unfolding actions in agricultural machinery. This is particularly useful for equipment that needs to be transported or stored in compact configurations. For example, telescopic cylinders can fold the wings of a tillage implement for easy transport on roads or through narrow gateways.

Stabilization and leveling:

Telescopic cylinders contribute to the stabilization and leveling of agricultural machinery. They are employed in tasks such as adjusting the height and angle of plows, cultivators, or balers to ensure proper ground engagement and uniform performance.

Advantages of telescopic cylinders in agricultural machinery:

Telescopic cylinders offer several advantages in agricultural machinery:

- Versatility: Telescopic cylinders can be used for various tasks, providing flexibility and adaptability in agricultural operations.

- Efficient force transmission: The telescopic design allows for direct and efficient force transmission, maximizing the equipment’s lifting and operational capabilities.

- Precise control: Telescopic cylinders enable precise control over movements, allowing for accurate positioning and improved productivity.

- Space optimization: Telescopic cylinders contribute to space optimization by enabling folding or compact configurations, facilitating transportation and storage of agricultural machinery.

Overall, telescopic cylinders are valuable components in agricultural machinery, offering versatility, efficient force transmission, precise control, and space optimization. They enhance the functionality and productivity of agricultural equipment across various tasks and applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in agricultural machinery.

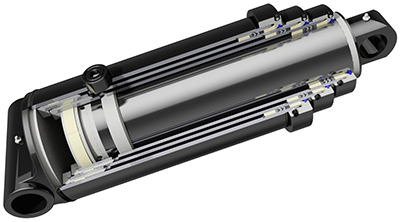

What is a telescopic cylinder and how does it work?

A telescopic cylinder is a type of hydraulic cylinder that consists of multiple nested stages or sections that can extend and retract, similar to a telescope. Here’s a detailed explanation:

A telescopic cylinder is primarily used when a long stroke length is required while maintaining a compact retracted length. It is commonly used in applications such as dump trucks, cranes, aerial platforms, and other equipment that require extended reach or height adjustment. Here’s how a telescopic cylinder works:

- Structure: A telescopic cylinder consists of a series of cylindrical stages or sleeves that are progressively nested inside one another. These stages are typically made of high-strength steel or aluminum alloy. The number of stages can vary depending on the specific design and application.

- Extension and Retraction: When the telescopic cylinder is in the retracted position, the stages are nested inside one another, with the smallest stage located at the base. To extend the cylinder, hydraulic fluid is supplied to the base of the cylinder, creating pressure that pushes the smallest stage outwards. As the smallest stage extends, it exposes the next larger stage, which is then pushed out by the hydraulic pressure. This process continues until all the stages have extended, resulting in a longer overall stroke length.

- Locking Mechanism: Telescopic cylinders often incorporate a locking mechanism to secure the extended stages in position. This mechanism ensures stability and prevents unintentional retraction of the cylinder under load. The locking mechanism can be mechanical, hydraulic, or a combination of both, depending on the design and application requirements.

- Retraction: To retract the telescopic cylinder, hydraulic fluid is supplied to the opposite side of the cylinder, typically to the largest stage. The hydraulic pressure acts on the largest stage, retracting it first. As each stage retracts, it nests inside the next smaller stage until the cylinder is fully retracted to its original compact length.

- Control and Stability: The extension and retraction of a telescopic cylinder are controlled by a hydraulic system. By regulating the flow and pressure of the hydraulic fluid, operators can precisely control the extension and retraction speed of the cylinder. The nested design of the stages provides stability and load-bearing capacity, allowing the telescopic cylinder to handle substantial loads.

The use of telescopic cylinders offers several benefits:

- Extended Stroke Length: Telescopic cylinders provide a significantly longer stroke length compared to traditional single-stage cylinders, enabling extended reach or height adjustment without increasing the overall size of the cylinder.

- Compact Design: The nested structure of telescopic cylinders allows for a compact retracted length, making them suitable for applications with space constraints.

- Versatility: Telescopic cylinders can be customized to meet specific stroke length requirements. The number of stages can be adjusted, and the cylinders can be designed for different load capacities and working conditions.

- Efficient Operation: The controlled extension and retraction of telescopic cylinders enable precise load handling and positioning, improving operational efficiency.

Overall, a telescopic cylinder is a hydraulic cylinder with nested stages that can extend and retract, providing an extended stroke length while maintaining a compact retracted length. Its structure and operation make it ideal for applications requiring long reach or height adjustment.

It’s important to follow the manufacturer’s guidelines and specifications for the telescopic cylinder, including proper maintenance and inspection, to ensure its safe and reliable operation.

editor by CX 2023-12-26

China Hot selling Multi-Stages Dump Truck Spare Part Hydraulic Telescopic Cylinder Made in China vacuum pump ac system

Product Description

Multi-Stages Dump Truck Spare Part Hydraulic Telescopic Cylinder Made in China

Product Specifications :

| Item | Specifications |

| Function | Lifting/lowering the truck body for cargo dumping |

| Bore diameter | 120mm-480mm,customizable |

| Bod diameter | 90mm-390mm,customizable |

| Stroke | 3000mm-12000mm,customizable |

| Stage | 2-6stages,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,customizable |

| Seal Type | Parker,NOK, Hallite or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Packaging | metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Product Display:

Mounting Method:

Appliactions:Mining Machinery,Mining Dump Truck

Other Related Products

Our Factory:

Quality Assurance:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection of Mechanical Properties of Raw Materials

Process Inspection

Final Testing

Packing & Delivery:

About US:

Our Certificate

Our Main Customers

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 600/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do telescopic cylinders contribute to energy-efficient equipment operation?

Telescopic cylinders play a significant role in promoting energy-efficient equipment operation. Here’s a detailed explanation:

Reduced energy consumption:

Telescopic cylinders are designed to minimize energy consumption during equipment operation. The hydraulic system of telescopic cylinders allows for precise control over the extension and retraction of the cylinder stages. This control enables the equipment to use the minimum amount of hydraulic fluid and energy required to achieve the desired movement or position.

Efficient force transmission:

Telescopic cylinders are engineered to efficiently transmit forces from the hydraulic system to the desired application. The telescopic design allows for a direct and linear transfer of force, reducing energy losses that can occur in more complex mechanical systems. This efficient force transmission ensures that the energy supplied to the telescopic cylinder is effectively utilized to perform the desired work.

Compactness and weight reduction:

Telescopic cylinders offer compactness in equipment design, which contributes to energy efficiency. By retracting the cylinder stages, the overall length of the equipment can be minimized, reducing weight and inertia. This reduction in weight and inertia requires less energy to start and stop the movement of the equipment, resulting in energy savings during operation.

Optimized design:

Telescopic cylinders are designed with efficiency in mind. Manufacturers consider factors such as the cylinder’s bore size, rod diameter, and overall construction to ensure optimal performance while minimizing energy requirements. By using lightweight and high-strength materials, optimizing the cylinder’s dimensions, and reducing internal friction, telescopic cylinders can operate efficiently and contribute to energy savings.

Controlled motion:

Telescopic cylinders provide precise and controlled motion, allowing equipment operators to perform tasks with accuracy and efficiency. The hydraulic control system in telescopic cylinders enables smooth and proportional extension and retraction, reducing the need for excessive force or multiple adjustments. This controlled motion prevents energy waste and ensures that the equipment operates efficiently.

Applications in energy-efficient equipment:

Telescopic cylinders are utilized in various energy-efficient equipment, such as hybrid or electric-powered machinery. These equipment types rely on the optimization of energy usage to minimize environmental impact and reduce operating costs. Telescopic cylinders contribute to these objectives by providing efficient force transmission, controlled motion, and compact design.

Furthermore, the integration of advanced technologies, such as electronic control systems, sensors, and feedback mechanisms, can enhance the energy efficiency of equipment that incorporates telescopic cylinders. These technologies allow for further optimization of hydraulic system performance, energy recovery, and intelligent control of equipment operations.

Overall, telescopic cylinders contribute to energy-efficient equipment operation through reduced energy consumption, efficient force transmission, compactness and weight reduction, optimized design, and controlled motion. By utilizing telescopic cylinders in equipment design and considering energy-efficient practices, industries can achieve more sustainable and economical operation.

Consulting with equipment manufacturers or industry experts can provide further insights into the energy-saving benefits and applications of telescopic cylinders in specific equipment types.

How do telescopic cylinders handle variations in cylinder size and capacity?

Telescopic cylinders are designed to handle variations in cylinder size and capacity effectively. Here’s a detailed explanation:

Modular design:

Telescopic cylinders feature a modular design that allows for flexibility in cylinder size and capacity. They consist of multiple stages or sections that retract inside one another, similar to a telescope. The number of stages can vary depending on the desired extended length and capacity of the cylinder. This modular design enables telescopic cylinders to be customized according to specific requirements.

Variable stroke length:

Telescopic cylinders offer the advantage of variable stroke length. The stroke length refers to the distance the cylinder can extend and retract. By adjusting the stroke length, the effective size and capacity of the telescopic cylinder can be modified. This flexibility allows for accommodating variations in the size and capacity requirements of different applications.

Increased capacity with additional stages:

Telescopic cylinders can handle variations in capacity by adding more stages to the cylinder. Each stage contributes to the overall capacity of the cylinder. By including additional stages, the cylinder’s capacity can be increased to handle higher loads or operate in more demanding conditions. This scalability makes telescopic cylinders suitable for a wide range of applications with varying capacity needs.

Proportional force distribution:

Telescopic cylinders distribute the applied force proportionally across the stages. As the cylinder extends, each stage contributes to supporting the load and transmitting the force. The force distribution ensures that the load is evenly distributed among the stages, allowing the cylinder to handle variations in capacity effectively.

Hydraulic control system:

Telescopic cylinders rely on a hydraulic control system for operation. The system allows for precise control over the extension and retraction of each stage. By adjusting the hydraulic pressure and flow, operators can regulate the movement and force exerted by the cylinder, ensuring optimal performance and capacity utilization.

Overall, telescopic cylinders handle variations in cylinder size and capacity through their modular design, variable stroke length, ability to add stages for increased capacity, proportional force distribution, and hydraulic control system. These features make telescopic cylinders adaptable to different applications and enable them to effectively handle varying size and capacity requirements.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the size, capacity, and operational considerations of telescopic cylinders.

Can telescopic cylinders be customized for specific machinery and equipment?

Yes, telescopic cylinders can be customized to meet the specific requirements of different machinery and equipment. Here’s a detailed explanation:

Customizable stroke length:

Telescopic cylinders can be designed and manufactured with customized stroke lengths to suit the specific needs of machinery and equipment. The stroke length determines the maximum extension or retraction distance of the cylinder and can be tailored to match the required range of motion for a particular application.

Adjustable force and speed:

The hydraulic control system of telescopic cylinders allows for adjustability in terms of force and speed. The system can be configured to provide the necessary force output for the machinery or equipment, ensuring optimal performance. Additionally, the speed of extension and retraction can be adjusted to match the operational requirements, enabling precise and efficient operation.

Mounting options:

Telescopic cylinders can be customized with different mounting options to facilitate easy integration with specific machinery and equipment. Mounting configurations can vary depending on factors such as available space, mounting orientation, and compatibility with existing systems. Manufacturers can provide various mounting solutions to ensure seamless installation.

Sealing and protection:

In certain applications, telescopic cylinders may require specialized sealing and protection features. Manufacturers can customize the cylinder design to incorporate seals and protective coatings that are suitable for the working environment. This customization helps enhance the longevity and reliability of the cylinder, especially in harsh operating conditions.

Material selection:

Telescopic cylinders can be manufactured using different materials to meet specific machinery and equipment requirements. Material selection depends on factors such as load capacity, operating temperature, corrosion resistance, and weight considerations. Manufacturers can offer material options to ensure the cylinder’s compatibility and performance in the intended application.

Integration with control systems:

Telescopic cylinders can be integrated with control systems and sensors to enable advanced functionality and automation. Customization may involve incorporating position sensors, pressure sensors, or other feedback devices to provide real-time data and enhance the overall performance and safety of the machinery or equipment.

Overall, telescopic cylinders can be customized in terms of stroke length, force and speed adjustability, mounting options, sealing and protection features, material selection, and integration with control systems. This customization allows telescopic cylinders to be tailored to the specific requirements of machinery and equipment, ensuring optimal performance and functionality.

It’s important to collaborate with the manufacturer or a qualified expert to determine the appropriate customization options and ensure compliance with relevant industry standards and regulations.

editor by CX 2023-12-26

China wholesaler Single Acting Multi Stage Telescopic Hydraulic Cylinder for Mining Dump Truck supplier

Product Description

Single Acting Multi Stage Telescopic Hydraulic Cylinder for Mining Dump Truck

Product Specifications :

| Item | Specifications |

| Function | Lifting/lowering the truck body for cargo dumping |

| Bore diameter | 120mm-480mm,customizable |

| Bod diameter | 90mm-390mm,customizable |

| Stroke | 3000mm-12000mm,customizable |

| Stage | 2-6stages,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,customizable |

| Seal Type | Parker,NOK, Hallite or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Packaging | metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Product Display:

Mounting Method:

Appliactions:Mining Machinery,Mining Dump Truck

Other Related Products

Our Factory:

Quality Assurance:

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Inspection of Mechanical Properties of Raw Materials

Process Inspection

Final Testing

Packing & Delivery:

About US:

Our Certificate

Our Main Customers

ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories.

As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

FAQ:

1, What does your company do?

A: we are a supplier of high quality hydraulic products including Hydraulic Cylinder, Hydraulic Motor, Hydraulic Power Pack, Hydraulic station and other Hydraulic components.

2, Are you a manufacture or a trading company?

A: We are a manufacturer.

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, CSA and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 45-60 days and the Motor need about 30-50 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 30% when order is confirmed and 70% before shipment. L/C is also acceptable for amount over 20,000USD.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 600/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do telescopic cylinders handle variations in load capacity and weight?

Telescopic cylinders are designed to handle variations in load capacity and weight effectively. Here’s a detailed explanation:

Load-specific design:

Telescopic cylinders are engineered with load-specific design considerations to accommodate variations in load capacity and weight. Manufacturers take into account factors such as the maximum expected load, the range of anticipated loads, and the required safety factors. The cylinder’s components, materials, and dimensions are selected and configured accordingly to provide the necessary strength and stability.

Multiple stages:

The nested structure of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for adaptability to different loads. Each stage can handle a specific portion of the load, and the collective capacity of all stages determines the overall load capacity of the cylinder. By adding or removing stages, telescopic cylinders can be customized to suit different load requirements, providing flexibility in handling variations in weight.

Hydraulic system control:

The hydraulic control system of telescopic cylinders plays a vital role in managing variations in load capacity. By regulating the flow of hydraulic fluid to each stage, operators can control the extension and retraction force applied to the cylinder. This control allows for adjustments based on the specific load and weight requirements, ensuring the cylinder operates within its safe working limits.

Pressure relief and overload protection:

Telescopic cylinders are often equipped with pressure relief valves and overload protection mechanisms to safeguard against excessive loads. Pressure relief valves help prevent over-pressurization of the hydraulic system by diverting excess fluid flow, protecting the cylinder from potential damage. Overload protection mechanisms, such as overload sensors or mechanical stops, are designed to activate and halt the cylinder’s movement if the load exceeds the safe operating limits.

Load distribution and stability:

Telescopic cylinders contribute to load distribution and stability. The nested design distributes the load across multiple stages, reducing stress on individual components and enhancing overall stability. Proper weight distribution on the machinery or equipment, as well as secure attachment of the load, further contribute to maintaining stability and ensuring safe operation.

It’s important to note that while telescopic cylinders can handle variations in load capacity and weight, it is crucial to operate within the specified load limits and follow the manufacturer’s guidelines. Exceeding the recommended load capacity can compromise the safety, performance, and longevity of the telescopic cylinder and the machinery it is installed on.

Consulting the manufacturer’s documentation, engineering specifications, and relevant industry standards is essential for understanding and adhering to the appropriate load capacity and weight guidelines when using telescopic cylinders.

Can telescopic cylinders be used in mining equipment for material transport?

Yes, telescopic cylinders are commonly used in mining equipment for material transport tasks. Here’s a detailed explanation:

Material loading and unloading:

Telescopic cylinders play a crucial role in loading and unloading materials in mining operations. They are utilized in equipment such as wheel loaders, excavators, and dump trucks. Telescopic cylinders enable the lifting and lowering of buckets, forks, or other material handling attachments, facilitating efficient material transport.

Extended reach:

In mining equipment, telescopic cylinders offer extended reach capabilities. This allows operators to access materials located at various distances, heights, or depths. The telescopic design of the cylinders enables them to extend and retract, providing the necessary reach for loading and unloading materials in mining applications.

Precise control:

Telescopic cylinders provide precise control over material transport movements. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, allowing operators to achieve accurate positioning and controlled movements during loading, unloading, and material placement. This precise control is essential for optimizing productivity and safety in mining operations.

Load handling capacity:

Telescopic cylinders are designed to handle heavy loads encountered in mining environments. They provide the necessary lifting force to transport large volumes of materials, such as ore, rocks, or overburden. The cylinders are engineered to withstand the demanding conditions of mining operations and ensure safe and efficient load handling.

Adaptability to terrain:

Mining equipment operates in diverse terrains, including uneven surfaces or steep inclines. Telescopic cylinders offer adaptability to varying terrain conditions. The extended reach and controlled movements provided by the cylinders allow operators to navigate challenging terrains and transport materials efficiently in mining sites.

Support for attachments:

Telescopic cylinders often support a range of attachments or tools that enhance material transport capabilities in mining equipment. For example, in wheel loaders, telescopic cylinders are used to extend the lifting arms, while different attachments such as buckets or forks facilitate the handling of various materials.

Advantages of telescopic cylinders in mining equipment:

Telescopic cylinders offer several advantages in material transport applications within mining:

- Extended reach: Telescopic cylinders enable operators to access materials located at varying distances or depths.

- Precise control: The hydraulic control system allows for accurate positioning and controlled movements, enhancing productivity and safety.

- Heavy-load handling: Telescopic cylinders provide the necessary lifting force to transport large volumes of materials encountered in mining operations.

- Adaptability to terrain: The extended reach and controlled movements of telescopic cylinders facilitate material transport in diverse mining terrains.

- Support for attachments: Telescopic cylinders can be used in conjunction with attachments or tools that enhance material handling capabilities in mining equipment.

Overall, telescopic cylinders are widely used in mining equipment for material transport tasks, offering extended reach, precise control, load handling capacity, adaptability to terrain, and support for attachments. They contribute to the efficiency, productivity, and safety of material transport operations in mining.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in mining equipment.

How does a telescopic cylinder contribute to precise reach and positioning?

A telescopic cylinder plays a crucial role in achieving precise reach and positioning in various applications. Here’s a detailed explanation:

Nested structure:

The nested structure of a telescopic cylinder, consisting of multiple stages or sleeves that retract inside one another, enables precise reach and positioning. Each stage can be extended or retracted individually, allowing for incremental adjustments in the cylinder’s length. This modular design provides fine-tuning capabilities, enabling operators to achieve the desired reach and positioning with accuracy.

Controlled extension and retraction:

The hydraulic control system of a telescopic cylinder ensures controlled extension and retraction of the stages. By regulating the flow of hydraulic fluid to each stage, operators can precisely control the speed and movement of the cylinder. This control allows for smooth and gradual extension or retraction, facilitating precise reach and positioning without abrupt or jerky movements.

Adjustable stroke length:

Telescopic cylinders offer the advantage of adjustable stroke length. The hydraulic system can be adjusted to vary the extension and retraction distance, allowing for customization based on the specific reach and positioning requirements of the application. This adjustability enables operators to adapt the cylinder’s stroke length to different tasks and working conditions, ensuring precise and optimized reach.

Position feedback systems:

In some applications, telescopic cylinders may be equipped with position feedback systems. These systems utilize sensors or transducers to provide real-time feedback on the cylinder’s extension or retraction position. By monitoring the position, operators can precisely track and control the reach and positioning of the cylinder, enhancing accuracy and repeatability.

Stability and rigidity:

Telescopic cylinders are designed to maintain stability and rigidity during operation. The nested structure, along with the hydraulic system, helps minimize unwanted oscillations or vibrations that could affect reach and positioning accuracy. This stability ensures that the cylinder maintains its intended position without undesired movement or deflection.

Overall, a telescopic cylinder contributes to precise reach and positioning through its nested structure, controlled extension and retraction, adjustable stroke length, position feedback systems (if equipped), and stability. These features enable operators to achieve accurate and repeatable reach and positioning in various applications.

It’s important to consult the manufacturer’s guidelines and specifications, as well as follow proper maintenance practices, to ensure the reliable and precise performance of telescopic cylinders in achieving reach and positioning requirements.

editor by CX 2023-12-26

China high quality Long Stroke Single Acting Multi Stage Telescopic Hydraulic Cylinder vacuum pump oil

Product Description

Long stroke single acting multi stage telescopic hydraulic cylinder

Product Description

Product Description:

| Work Press | 7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

| Material | Aluminum,Cast Iron,45mnb Steel,Stainless Steel, carbon steel |

| Bore Size | 120mm-380mm, Customizable |

| Rod size | 90mm-350mm, Customizable |

| Stage | 2~6 stages |

| Paint Color | Red,Yellow,Blue,Brown,Customizable |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,Customizable |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Delivery Time | 7-15 Days,Also depands on specific demands |

| Certification | ISO9001,CE, SGS |

Product Display:

Quality Assurance

| Inspection Type | Inspection Standard |

| Raw Material Inspection | Before storage, QC takes the measurement of the raw materials. |

| Process Material Inspection | During the production, QCs conduct a random inspection. Before the hydraulic cylinder parts transferred to the next process, QCs takes inspection. |

| Final Function Testing | All the hydraulic cylinders take hydraulic function test |

Mounting Method:

Our Factory:

About US:

Tianjian Hydraulic. is a leader in the engineering design and manufacture of high pressure hydraulic cylinders that are widely used in the fields of mining, metallurgy, construction machinery, marine, offshore, water engineering, wind power, hydraulic press, agricultural machinery, and so on.

The Tianjian team has almost 8 years experience delivering innovative and dependable solutions to meet OEM high pressure hydraulic cylinder needs.

If possible, when contact with us, please apply information as below

|

Bore |

Rod |

Stroke |

Work Pressure |

Mounting |

Work environment |

|

|

|

|

|

|

|

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes.

And if you have samples, we can manufacture according to your samples after sending to us.

Welcome to our factory if you have any time.

Your satisfaction is our biggest motivation.

Now, you can contact with us for any question or inquiry.

Packing & Delivery:

Appliactions:

Application:mining truck

FAQ:

1, What does your company do?

A: we are a supplier of high quality Hydraulic Cylinder for more than 8 years.

2, Are you a manufacture or a trading company?

A: We are a manufacturer. Warmly welcome to visit us!

3, What certificate do you have?

A: All our factories are ISO certificated. And our main suppliers of materials and parts are with CE, RoHS, and UL certificates.

4, How long is your delivery time?

A: The delivery time depends on different products and quantity. The cylinder usually need about 15-60 days.

5, Can you make parts as customer’s requirement or drawing?

A: Yes, we can OEM for you as your drawings. Our engineer also can give you professional support for technical suggestions.

6, What kind of payment terms do you accept?

A: We prefer T/T through bank. 3% when order is confirmed and 70% before shipment.

7, What is your warranty policy?

A: All our products are warranted for 1 full year from date of delivery against defects in materials and workmanship. This warranty does not cover parts that are worn out through the course of normal operation or are damaged through negligence. We serious remind that unclean hydraulic oil will definitely cause damage to your Hydraulic components. And this damage is not included in the warranty range. So we strongly suggest you to use new clean oil or make sure the system oil are clean when using our parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do telescopic cylinders handle variations in load capacity and weight?

Telescopic cylinders are designed to handle variations in load capacity and weight effectively. Here’s a detailed explanation:

Load-specific design:

Telescopic cylinders are engineered with load-specific design considerations to accommodate variations in load capacity and weight. Manufacturers take into account factors such as the maximum expected load, the range of anticipated loads, and the required safety factors. The cylinder’s components, materials, and dimensions are selected and configured accordingly to provide the necessary strength and stability.

Multiple stages:

The nested structure of telescopic cylinders, with multiple stages or sleeves that retract inside one another, allows for adaptability to different loads. Each stage can handle a specific portion of the load, and the collective capacity of all stages determines the overall load capacity of the cylinder. By adding or removing stages, telescopic cylinders can be customized to suit different load requirements, providing flexibility in handling variations in weight.

Hydraulic system control:

The hydraulic control system of telescopic cylinders plays a vital role in managing variations in load capacity. By regulating the flow of hydraulic fluid to each stage, operators can control the extension and retraction force applied to the cylinder. This control allows for adjustments based on the specific load and weight requirements, ensuring the cylinder operates within its safe working limits.

Pressure relief and overload protection:

Telescopic cylinders are often equipped with pressure relief valves and overload protection mechanisms to safeguard against excessive loads. Pressure relief valves help prevent over-pressurization of the hydraulic system by diverting excess fluid flow, protecting the cylinder from potential damage. Overload protection mechanisms, such as overload sensors or mechanical stops, are designed to activate and halt the cylinder’s movement if the load exceeds the safe operating limits.

Load distribution and stability:

Telescopic cylinders contribute to load distribution and stability. The nested design distributes the load across multiple stages, reducing stress on individual components and enhancing overall stability. Proper weight distribution on the machinery or equipment, as well as secure attachment of the load, further contribute to maintaining stability and ensuring safe operation.

It’s important to note that while telescopic cylinders can handle variations in load capacity and weight, it is crucial to operate within the specified load limits and follow the manufacturer’s guidelines. Exceeding the recommended load capacity can compromise the safety, performance, and longevity of the telescopic cylinder and the machinery it is installed on.

Consulting the manufacturer’s documentation, engineering specifications, and relevant industry standards is essential for understanding and adhering to the appropriate load capacity and weight guidelines when using telescopic cylinders.

How do telescopic cylinders handle variations in hydraulic pressure and flow rate?

Telescopic cylinders are designed to handle variations in hydraulic pressure and flow rate effectively. Here’s a detailed explanation:

Hydraulic pressure control:

Telescopic cylinders are equipped with hydraulic systems that allow for precise control of hydraulic pressure. The hydraulic pressure is regulated by a pump that supplies pressurized hydraulic fluid to the cylinder. The pressure can be adjusted according to the specific requirements of the application.

Pressure relief valves:

To handle variations in hydraulic pressure, telescopic cylinders often incorporate pressure relief valves. These valves are designed to limit the maximum pressure within the cylinder to prevent damage or failure. When the pressure exceeds the set limit, the relief valve opens, allowing excess fluid to bypass and relieve the pressure. This ensures the safety and integrity of the telescopic cylinder and the hydraulic system.

Flow control:

Telescopic cylinders also handle variations in flow rate through the hydraulic control system. The flow rate of hydraulic fluid into and out of the cylinder determines the speed of extension and retraction. Flow control valves, such as flow restrictors or flow control valves, are commonly employed to regulate the flow rate.

Flow restrictors:

Flow restrictors are used to limit the flow rate of hydraulic fluid entering or leaving the telescopic cylinder. By restricting the flow, the speed of extension or retraction can be controlled. This allows for precise and gradual movement, preventing abrupt or uncontrolled motion.

Flow control valves:

Flow control valves are designed to provide adjustable flow rates by regulating the opening or closing of hydraulic passages. These valves allow operators to control the speed of extension and retraction of the telescopic cylinder. By adjusting the flow control valves, variations in flow rate can be accommodated to suit specific operational requirements.

Sequencing valves:

In some applications, telescopic cylinders may require a specific sequence of extension and retraction. Sequencing valves are used to control the order in which different stages of the telescopic cylinder extend or retract. These valves ensure proper synchronization of the cylinder stages and prevent uneven or unbalanced movement.

Overall, telescopic cylinders employ various hydraulic components and control mechanisms to handle variations in hydraulic pressure and flow rate. Pressure relief valves protect against excessive pressure, flow restrictors and flow control valves regulate the flow rate, and sequencing valves ensure proper sequencing of cylinder stages. These features allow telescopic cylinders to operate safely, precisely, and efficiently under different hydraulic conditions.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the hydraulic system and control mechanisms of telescopic cylinders, as well as recommended maintenance and safety practices.

What is a telescopic cylinder and how does it work?

A telescopic cylinder is a type of hydraulic cylinder that consists of multiple nested stages or sections that can extend and retract, similar to a telescope. Here’s a detailed explanation:

A telescopic cylinder is primarily used when a long stroke length is required while maintaining a compact retracted length. It is commonly used in applications such as dump trucks, cranes, aerial platforms, and other equipment that require extended reach or height adjustment. Here’s how a telescopic cylinder works:

- Structure: A telescopic cylinder consists of a series of cylindrical stages or sleeves that are progressively nested inside one another. These stages are typically made of high-strength steel or aluminum alloy. The number of stages can vary depending on the specific design and application.

- Extension and Retraction: When the telescopic cylinder is in the retracted position, the stages are nested inside one another, with the smallest stage located at the base. To extend the cylinder, hydraulic fluid is supplied to the base of the cylinder, creating pressure that pushes the smallest stage outwards. As the smallest stage extends, it exposes the next larger stage, which is then pushed out by the hydraulic pressure. This process continues until all the stages have extended, resulting in a longer overall stroke length.

- Locking Mechanism: Telescopic cylinders often incorporate a locking mechanism to secure the extended stages in position. This mechanism ensures stability and prevents unintentional retraction of the cylinder under load. The locking mechanism can be mechanical, hydraulic, or a combination of both, depending on the design and application requirements.

- Retraction: To retract the telescopic cylinder, hydraulic fluid is supplied to the opposite side of the cylinder, typically to the largest stage. The hydraulic pressure acts on the largest stage, retracting it first. As each stage retracts, it nests inside the next smaller stage until the cylinder is fully retracted to its original compact length.

- Control and Stability: The extension and retraction of a telescopic cylinder are controlled by a hydraulic system. By regulating the flow and pressure of the hydraulic fluid, operators can precisely control the extension and retraction speed of the cylinder. The nested design of the stages provides stability and load-bearing capacity, allowing the telescopic cylinder to handle substantial loads.

The use of telescopic cylinders offers several benefits:

- Extended Stroke Length: Telescopic cylinders provide a significantly longer stroke length compared to traditional single-stage cylinders, enabling extended reach or height adjustment without increasing the overall size of the cylinder.

- Compact Design: The nested structure of telescopic cylinders allows for a compact retracted length, making them suitable for applications with space constraints.

- Versatility: Telescopic cylinders can be customized to meet specific stroke length requirements. The number of stages can be adjusted, and the cylinders can be designed for different load capacities and working conditions.

- Efficient Operation: The controlled extension and retraction of telescopic cylinders enable precise load handling and positioning, improving operational efficiency.

Overall, a telescopic cylinder is a hydraulic cylinder with nested stages that can extend and retract, providing an extended stroke length while maintaining a compact retracted length. Its structure and operation make it ideal for applications requiring long reach or height adjustment.

It’s important to follow the manufacturer’s guidelines and specifications for the telescopic cylinder, including proper maintenance and inspection, to ensure its safe and reliable operation.

editor by CX 2023-12-25

China supplier Dump Truck Front End Loader Multi Stage Telescopic Hydraulic Lift Cylinder Made in China vacuum pump adapter

Product Description

Dump Truck Front End Loader Multi Stage Telescopic Hydraulic Lift Cylinder Made in China

Product Specifications :

| Item | Specifications |

| Function | Lifting/lowering the truck body for cargo dumping |

| Bore diameter | 120mm-480mm,customizable |

| Bod diameter | 90mm-390mm,customizable |

| Stroke | 3000mm-12000mm,customizable |

| Stage | 2-6stages,customizable |

| Surface treatment of piston rod | HaHard Chrome Plating,Electroplated Milky White Chromium+Hard Chromium,Nickel Plating+Hard Chromium Plating,High-Velocity Oxygen-Fuel CrC NiC,Ceramic Coating,Nitriding,Laser Cladding |

| Work Pressure | Maximum 38MPa,customizable |

| Material | High tensile cold drawn tube, precision honed for extended seal life |

| Mounting | Earring,Flange,Clevis.Foot,Trunnion,customizable |

| Seal Type | Parker,NOK, Hallite or as customer’s requirement |

| Warrenty | 18 months |

| MOQ | 1 pcs |

| Production Time | Based on order quantity.normally 30-40 days. |

| Certification | ISO9001,CE, SGS |

| Packaging | metal case,plywood case,carton or as requirement |

| Service | OEM & ODM |

| Price Advantage | Competitive factory price with guaranteed quality |

| Business Type | Manufacturer |

Product Display:

Mounting Method: