Product Description

Product Description

| Bore of cylinder’s first stage | Stroke | Upper mouting | Upper mouting | Mounting dimension | Working pressure | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Diameter of the hole | Deep | Diameter of the hole | Deep | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 84. (Any time call availab)

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do telescopic cylinders handle variations in environmental conditions?Telescopic cylinders are designed to handle variations in environmental conditions effectively. Here’s a detailed explanation: Durable construction: Telescopic cylinders are constructed with durable materials such as steel or high-strength alloys, which provide resistance to environmental elements. These materials are chosen for their ability to withstand harsh conditions, including temperature extremes, moisture, and exposure to chemicals or corrosive substances. Sealing mechanisms: Telescopic cylinders incorporate sealing mechanisms to protect the internal components from contaminants and maintain proper operation in different environments. The seals prevent the entry of dust, dirt, water, and other particles that could potentially damage the cylinder’s internal components or affect its performance. Seals also help retain the hydraulic fluid, ensuring optimal lubrication and preventing leakage. Corrosion resistance: Telescopic cylinders are often coated with protective finishes or treatments to enhance their corrosion resistance. These coatings, such as paint, powder coating, or specialized coatings like chrome plating, create a barrier between the cylinder’s surface and the surrounding environment, reducing the risk of corrosion. Corrosion-resistant materials and treatments are particularly crucial in outdoor or marine applications where exposure to moisture, saltwater, or chemicals is common. Temperature considerations: Telescopic cylinders are designed to handle variations in temperature. The materials used in their construction are selected to withstand both low and high temperature ranges. Additionally, the hydraulic fluid used in the cylinders is chosen based on its ability to maintain consistent performance across different temperature conditions. In extreme temperature environments, additional insulation or heating elements may be incorporated to ensure proper fluid viscosity and prevent freezing or overheating. Environmental sealing: In certain applications where telescopic cylinders are exposed to extreme environmental conditions, additional sealing measures may be implemented. Environmental seals are designed to provide extra protection against water, dust, or other contaminants that are prevalent in specific environments. These seals are typically more robust and durable to maintain the integrity of the cylinder in challenging conditions. Regular maintenance: To ensure optimal performance and longevity, regular maintenance is essential for telescopic cylinders. This includes inspecting and cleaning the cylinders, checking and replacing worn seals, monitoring fluid levels and quality, and addressing any signs of damage or wear. Maintenance intervals may vary depending on the operating conditions and manufacturer recommendations. Overall, telescopic cylinders are engineered to handle variations in environmental conditions by incorporating durable construction, sealing mechanisms, corrosion resistance, temperature considerations, environmental sealing, and regular maintenance. These features contribute to the reliability, longevity, and performance of telescopic cylinders in diverse industrial applications. Consulting with manufacturers or industry experts can provide further guidance on selecting telescopic cylinders that are suitable for specific environmental conditions.

Can telescopic cylinders be used in manufacturing machinery for material processing?Yes, telescopic cylinders are commonly used in manufacturing machinery for material processing tasks. Here’s a detailed explanation: Material handling and manipulation: Telescopic cylinders are utilized in manufacturing machinery to handle and manipulate materials during the processing stages. They enable lifting, lowering, pushing, or pulling of components, parts, or raw materials, facilitating various manufacturing operations such as cutting, bending, shaping, or assembly. Positioning and alignment: Telescopic cylinders contribute to precise positioning and alignment of materials in manufacturing machinery. The controlled extension and retraction of the cylinders allow operators to align workpieces accurately, ensuring consistent quality, dimensional accuracy, and proper fit during material processing. Adjustable working height: In manufacturing machinery, telescopic cylinders provide the advantage of adjustable working height. By extending or retracting the cylinders, the height of the work surface or processing area can be modified to accommodate different material sizes or operator preferences. This flexibility enhances ergonomics and facilitates efficient material processing. Modular design for customization: Telescopic cylinders feature a modular design that allows for customization according to specific manufacturing requirements. The number of stages or sections can be adjusted to achieve the desired extended length and capacity of the cylinder. This modularity enables telescopic cylinders to be tailored to the dimensions and processing needs of different manufacturing machinery. Force generation and control: Telescopic cylinders generate the necessary force to perform material processing tasks. The hydraulic control system regulates the extension and retraction of the cylinders, allowing operators to control the force applied during cutting, bending, or other processing operations. This force control ensures precise and consistent material processing while minimizing the risk of damage or deformation. Space optimization: Telescopic cylinders contribute to space optimization in manufacturing machinery. Their compact design allows for efficient utilization of available space, especially in equipment with limited footprint. The telescopic nature of the cylinders enables them to retract when not in use, minimizing the space occupied and allowing for better overall layout and arrangement of the machinery. Advantages of telescopic cylinders in manufacturing machinery: Telescopic cylinders offer several advantages in material processing applications within manufacturing machinery:

Overall, telescopic cylinders are widely used in manufacturing machinery for material processing tasks, providing material handling, positioning, and force control capabilities. Their flexibility, modularity, and precise control contribute to efficient and accurate material processing operations in manufacturing. It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in manufacturing machinery.

What is a telescopic cylinder and how does it work?A telescopic cylinder is a type of hydraulic cylinder that consists of multiple nested stages or sections that can extend and retract, similar to a telescope. Here’s a detailed explanation: A telescopic cylinder is primarily used when a long stroke length is required while maintaining a compact retracted length. It is commonly used in applications such as dump trucks, cranes, aerial platforms, and other equipment that require extended reach or height adjustment. Here’s how a telescopic cylinder works:

The use of telescopic cylinders offers several benefits:

Overall, a telescopic cylinder is a hydraulic cylinder with nested stages that can extend and retract, providing an extended stroke length while maintaining a compact retracted length. Its structure and operation make it ideal for applications requiring long reach or height adjustment. It’s important to follow the manufacturer’s guidelines and specifications for the telescopic cylinder, including proper maintenance and inspection, to ensure its safe and reliable operation.

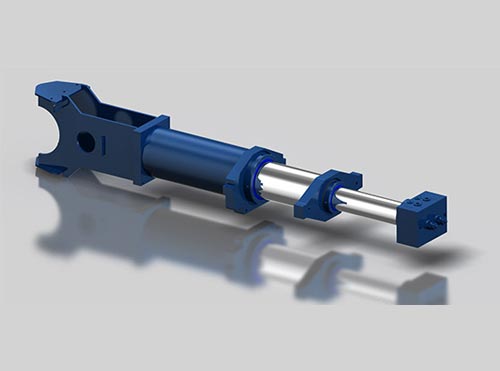

China factory Hydraulic Cylinder Telescopic for Construction Eh280-160-400 Zlp076 vacuum pump and compressorProduct Description

1.Main Description

ETERNAL company design and manufacture heavy duty hydraulic cylinders that covering the following fields:

Ø hydraulic press cylinder Ø construction machinery cylinder Ø mining machinery cylinder Ø metallurgy machinery cylinder Ø water power project cylinder Ø marine hydraulic cylinder Ø servo hydraulic cylinder

2. Design

Not only we could manufacture all kinds of hydraulic cylinders according to the drawing from our customers,but also we could make a design according to customer’s requirements.If you require our engineer to make a design,pls advise us the following specification:

1. Rated pressure 2. Working pressure 3. Test pressure 4. Working condition and environment ,for example ,temperature ,working frequency 5. Pulling force ,and return stroke force 6. Pulling and return speed 7. Assembly size 8. Seal ring requirements .For example , brand ,seal material etc . 9. Tube and piston rod raw material requirements 10. Piston rod surface treatment requirements, for example chromating film thickness , Surface hardness etc . 11. Painting and other spare parts requirements .

3. Manufacturing capability and cylinder size range

3.1 Cylinder bore diameter :max Ø1200mm 3.2 Cylinder length :10Meter 3.3 Max lifting capability :50 Tons

4.Manufacturing and inspection

4.1.Cylinder tube size and choice

4.1.1 According to the cylinder pressure and inside diameter size ,different steel tube Would be choosed .

1. ID ≤300mm , cold rolled precision seamless tube would be choosed 2. 300mm≤ID ≤500mm , hot rolled seamless tube would be choosed 3. 500mm≤ID ≤1000mm, forged tube would be choosed

4.1.2 Cylinder tube steel grade : SAE1571 , SAE1045 ,27SiMn , S355JR ,S355J2G3 St52-3 ,SUS304 ,SUS316L etc . 4.1.3 Cylinder tube inside boring and honing , roughness R0.2-R0.3,

4.1.4 Cylinder tube inside chromating : if necessary ,tube inside chromating could be applied . 4.2 Piston rod is a very important part for hydraulic cylinder .

4.2.1 Piston rod steel grade : SAE1045, 42CrMo4, SUS410 ,SUS420, SUS304, SUS316L

4.2.2 Piston rod chromating and surface hardness . Eternal company ensure that every piece piston rod would be surface hardened before chromating , surface hardness is HRC55~60 , Chromating film thickness is 0.03~0.04mm if there is no other specific requirements .

4.3 Seal ring and O ring

According to the customers’ requirements and working condition , eternal company would choose suitable seal ring kit , seal ring brand include :Parker , Merkel , NOK , HangZhou Rubber institute , ZheJiang brand etc . Eternal company would supply suitable seal solution for their customer so that hydraulic cylinder has more lifetime , easy maintenance and simple repairing .

4.4 Tube and flange welding

The welding on cylinder tube and flange would be Ultrasonic tested every time , the welding seam would be cleaned before machining .Eternal company ensure that every welding seam has no any leak during lifetime

4.5 Assembly and pressure test

Before hydraulic cylinder is assemblied , every spare parts would be measured and cleaned .After hydraulic cylinder is assemblied , pressure test would be carried out one By one , eternal company ensure that testing pressure is higher 30%-50% than working pressure , and pressure holding time 30~60 minutes is necessary . Every piece hydraulic cylinder must be tested completely without any leak .

4.6 Painting and storage .

After hydraulic cylinder pass through pressure test , painting is necessary .

Processing

HangZhou CHINAMFG Heavy Industry Co., Ltd was established in 22, Apr. 2008. Our products mainly including: hydraulic baler, hydraulic shear, hydraulic cylinder and metallurgical Equipment. We could manufacture all kinds of hydraulic baler and hydraulic shear, pressure up to 1000 tons, and our machines have been exported to many countries.We specialize on design and manufacture heavy duty hydraulic cylinders , scrap baler machine and shearing machine .Our hydraulic cylinders are widely used in different industry fields including:construction machinery,mining machinery, hydro~power project, offshore drilling platform, steel plant equipment , marine machinery,hydraulic lifting system etc. We have gained 10 patents for our hydraulic cylinders. In 2008, our servo cylinders with cylinder bore 950mm for steel mill were exported to Poland.In 2009, our hydraulic cylinders with stroke 10 CHINAMFG were exported to Pakistan for water conservancy project. In 2016,cyliner with weight 90tons has been exported to Russian sucessfully . Our hydraulic cylinder range: Bore:1000mm, Stroke:12 meter, testing pressure:50MPa We could make all kinds of hydraulic baler , hydraulic shear , scrap steel shredder machine , etc rated from 100 tons -1250tons . We could make all kinds of excavator spare parts , drill rig spare parts , steel mill spare parts according to OEM drawing , including all kinds of shaft and drill tools . We have heavy duty workshop with area 10000 square meters. There is doublelayer crane in the workshop.The lifting height could reach to 16 meter while lifting capacity could reach to 75 tons. Our machining equipment including Horizontal Lathe (11 meter ), Vertical CNC Machining Center, Display boring and milling machine, Frame type CNC machining center,CNC Lathe, Deep hole boring machine (13 meter), honing machine,etc. Testing equipment including Intelligent Pressure Test Machine, UT Detector, MT Detector, Chrome Thickness Meter, etc. Eternal company would devote to supply first rate equipment and provide total solutionsto our customer. In the past 10 years, we devoted ourself to continuous market expanding and the researchand development of new products. Till now, our products have been export to nearly 50 countries and own good reputation from our customers . FAQ 2. how can we guarantee quality? 3.what can you buy from us? 4. why should you buy from us not from other suppliers? 5. what services can we provide?

How do telescopic cylinders contribute to energy-efficient equipment operation?Telescopic cylinders play a significant role in promoting energy-efficient equipment operation. Here’s a detailed explanation: Reduced energy consumption: Telescopic cylinders are designed to minimize energy consumption during equipment operation. The hydraulic system of telescopic cylinders allows for precise control over the extension and retraction of the cylinder stages. This control enables the equipment to use the minimum amount of hydraulic fluid and energy required to achieve the desired movement or position. Efficient force transmission: Telescopic cylinders are engineered to efficiently transmit forces from the hydraulic system to the desired application. The telescopic design allows for a direct and linear transfer of force, reducing energy losses that can occur in more complex mechanical systems. This efficient force transmission ensures that the energy supplied to the telescopic cylinder is effectively utilized to perform the desired work. Compactness and weight reduction: Telescopic cylinders offer compactness in equipment design, which contributes to energy efficiency. By retracting the cylinder stages, the overall length of the equipment can be minimized, reducing weight and inertia. This reduction in weight and inertia requires less energy to start and stop the movement of the equipment, resulting in energy savings during operation. Optimized design: Telescopic cylinders are designed with efficiency in mind. Manufacturers consider factors such as the cylinder’s bore size, rod diameter, and overall construction to ensure optimal performance while minimizing energy requirements. By using lightweight and high-strength materials, optimizing the cylinder’s dimensions, and reducing internal friction, telescopic cylinders can operate efficiently and contribute to energy savings. Controlled motion: Telescopic cylinders provide precise and controlled motion, allowing equipment operators to perform tasks with accuracy and efficiency. The hydraulic control system in telescopic cylinders enables smooth and proportional extension and retraction, reducing the need for excessive force or multiple adjustments. This controlled motion prevents energy waste and ensures that the equipment operates efficiently. Applications in energy-efficient equipment: Telescopic cylinders are utilized in various energy-efficient equipment, such as hybrid or electric-powered machinery. These equipment types rely on the optimization of energy usage to minimize environmental impact and reduce operating costs. Telescopic cylinders contribute to these objectives by providing efficient force transmission, controlled motion, and compact design. Furthermore, the integration of advanced technologies, such as electronic control systems, sensors, and feedback mechanisms, can enhance the energy efficiency of equipment that incorporates telescopic cylinders. These technologies allow for further optimization of hydraulic system performance, energy recovery, and intelligent control of equipment operations. Overall, telescopic cylinders contribute to energy-efficient equipment operation through reduced energy consumption, efficient force transmission, compactness and weight reduction, optimized design, and controlled motion. By utilizing telescopic cylinders in equipment design and considering energy-efficient practices, industries can achieve more sustainable and economical operation. Consulting with equipment manufacturers or industry experts can provide further insights into the energy-saving benefits and applications of telescopic cylinders in specific equipment types.

Can telescopic cylinders be used in forestry equipment for tree handling?Yes, telescopic cylinders are commonly used in forestry equipment for tree handling tasks. Here’s a detailed explanation: Tree felling and extraction: Telescopic cylinders play a vital role in tree felling and extraction operations. They are utilized in equipment such as feller bunchers, harvesters, and forwarders. Telescopic cylinders provide the necessary force to cut down trees and extract them from the forest. The cylinders are used in combination with cutting heads, grapples, or clamps to grip, hold, and manipulate trees during the felling and extraction processes. Boom and arm extension: In forestry equipment, telescopic cylinders are employed to extend the booms and arms of machinery. This extension capability allows operators to reach trees located at various distances and heights, facilitating efficient tree handling. Telescopic cylinders enable the equipment to adapt to different tree sizes and positions, enhancing productivity and reducing manual labor. Precise control: Telescopic cylinders provide precise control over tree handling movements. The hydraulic control system allows operators to extend and retract the cylinders with accuracy, enabling controlled positioning of trees during felling, extraction, or stacking. This precise control is crucial for ensuring operator safety, preventing damage to the equipment or surrounding environment, and optimizing operational efficiency. Load handling and stacking: Telescopic cylinders support load handling and stacking operations in forestry equipment. They provide the necessary lifting force to handle tree logs and facilitate stacking for transportation or processing. The cylinders work in conjunction with grapples, forks, or other attachments to securely grip and manipulate tree logs during loading, unloading, or stacking activities. Stability and balance: Telescopic cylinders contribute to the stability and balance of forestry equipment during tree handling tasks. The controlled extension and retraction of the cylinders help maintain the proper weight distribution and prevent tipping or imbalance when handling heavy tree logs. This ensures the safety of operators and equipment in challenging forestry environments. Advantages of telescopic cylinders in forestry equipment: Telescopic cylinders offer several advantages in tree handling applications:

Overall, telescopic cylinders are widely used in forestry equipment for tree handling tasks, offering extended reach, precise control, efficient load handling, adaptability, and stability. They enhance the productivity, safety, and efficiency of forestry operations. It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in forestry equipment.

What are the components and design features of a telescopic cylinder?A telescopic cylinder consists of various components and incorporates specific design features to enable its functionality and performance. Here’s a detailed explanation: Components of a telescopic cylinder:

Design features of a telescopic cylinder:

These components and design features work together to enable the functionality, reliability, and performance of a telescopic cylinder. It’s important to consult the manufacturer’s guidelines and specifications for proper installation, operation, and maintenance of the telescopic cylinder based on the specific application requirements.

China Professional Competitive Price 16MPa Working Pressure Project 10ton Agricultural Tipper Farming Telescopic Hydraulic Cylinder vacuum pump distributorsProduct Description

Product Description A: Product Description

Product Parameters

CATALOGUE OF HYDRAULIC CYLINDERS

Application Hydraulic cylinder can application for Excavator, Forklift, Snowplow, Farm Cultivator, Metallurgical Machinery, Agricultural Machinery, Forest Machinery, Construction Machinery and more.

Our service/certifications —CE Certificate of Quality Checked Company Profile

CHINAMFG is a leading global designer, manufacturer and marketer of hydraulic cylinder,cab, oil tank, counterweight, boom, arm, bucket, chassis, outrigger, pipe, hose, fitting, valve block, tyre, wheel,and other parts. Products are widely used in construction, mining, crane, material handing, automobile, truck, transportation, oil and gas, farm and garden equipment and so on . FAQ 1)>. How about your delivery time? 2)>. What is your terms of price? 3)> . What is your terms of payment? 4)> . Can you supply a sample freely? 5)> Can you produce according to the samples? 6)>. What is your sample policy? 7)>. Do you test all your goods before delivery? 8)>: How do you make our business long-term and good relationship? /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can telescopic cylinders be used in material handling equipment for reach and lift?Yes, telescopic cylinders are commonly used in material handling equipment to provide reach and lift capabilities. Here’s a detailed explanation: Role in material handling: Telescopic cylinders play a crucial role in material handling equipment by extending the reach and enabling the lifting of heavy loads. These cylinders are typically employed in equipment such as forklifts, telehandlers, reach stackers, and aerial work platforms. Reach extension: Telescopic cylinders allow material handling equipment to extend their reach by extending the boom or lifting arm. The nested design of the cylinder, with multiple stages that retract inside one another, enables the equipment to achieve a longer reach when required. By extending the telescopic cylinder, operators can access materials at greater heights or reach into confined spaces. Lifting capacity: Telescopic cylinders provide the necessary lifting force to handle heavy loads in material handling equipment. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and ensure safe and efficient load handling. Precision control: Telescopic cylinders offer precise control over the extension and retraction of the lifting arm or boom. The hydraulic control system regulates the flow of hydraulic fluid to each stage of the cylinder, allowing for smooth and controlled movement. This precise control is essential in material handling applications to ensure accurate positioning of loads and safe operation. Compactness and flexibility: Telescopic cylinders contribute to the compactness and flexibility of material handling equipment. By retracting the cylinder stages, the overall length of the equipment can be minimized, making it easier to maneuver in tight spaces. Additionally, the ability to extend and retract the telescopic cylinder provides flexibility in adjusting the reach and adapting to different working conditions. Variety of material handling equipment: Telescopic cylinders are utilized in a wide range of material handling equipment to enhance reach and lift capabilities. Forklifts, for example, often incorporate telescopic cylinders to extend the forks and reach into pallet racks. Telehandlers and reach stackers utilize telescopic cylinders to extend the lifting arm and reach high stacking heights. Aerial work platforms utilize telescopic cylinders to extend the platform and provide elevated access for maintenance or construction tasks. Advantages of telescopic cylinders in material handling: Telescopic cylinders offer several advantages in material handling equipment:

Overall, telescopic cylinders are widely used in material handling equipment to extend reach and enhance lifting capabilities. Their precise control, compactness, and flexibility make them essential components in various material handling applications. It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

Can telescopic cylinders be used in manufacturing machinery for material processing?Yes, telescopic cylinders are commonly used in manufacturing machinery for material processing tasks. Here’s a detailed explanation: Material handling and manipulation: Telescopic cylinders are utilized in manufacturing machinery to handle and manipulate materials during the processing stages. They enable lifting, lowering, pushing, or pulling of components, parts, or raw materials, facilitating various manufacturing operations such as cutting, bending, shaping, or assembly. Positioning and alignment: Telescopic cylinders contribute to precise positioning and alignment of materials in manufacturing machinery. The controlled extension and retraction of the cylinders allow operators to align workpieces accurately, ensuring consistent quality, dimensional accuracy, and proper fit during material processing. Adjustable working height: In manufacturing machinery, telescopic cylinders provide the advantage of adjustable working height. By extending or retracting the cylinders, the height of the work surface or processing area can be modified to accommodate different material sizes or operator preferences. This flexibility enhances ergonomics and facilitates efficient material processing. Modular design for customization: Telescopic cylinders feature a modular design that allows for customization according to specific manufacturing requirements. The number of stages or sections can be adjusted to achieve the desired extended length and capacity of the cylinder. This modularity enables telescopic cylinders to be tailored to the dimensions and processing needs of different manufacturing machinery. Force generation and control: Telescopic cylinders generate the necessary force to perform material processing tasks. The hydraulic control system regulates the extension and retraction of the cylinders, allowing operators to control the force applied during cutting, bending, or other processing operations. This force control ensures precise and consistent material processing while minimizing the risk of damage or deformation. Space optimization: Telescopic cylinders contribute to space optimization in manufacturing machinery. Their compact design allows for efficient utilization of available space, especially in equipment with limited footprint. The telescopic nature of the cylinders enables them to retract when not in use, minimizing the space occupied and allowing for better overall layout and arrangement of the machinery. Advantages of telescopic cylinders in manufacturing machinery: Telescopic cylinders offer several advantages in material processing applications within manufacturing machinery:

Overall, telescopic cylinders are widely used in manufacturing machinery for material processing tasks, providing material handling, positioning, and force control capabilities. Their flexibility, modularity, and precise control contribute to efficient and accurate material processing operations in manufacturing. It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in manufacturing machinery.

How does a telescopic cylinder differ from standard hydraulic cylinders?A telescopic cylinder differs from standard hydraulic cylinders in several ways. Here’s a detailed explanation: A telescopic cylinder, also known as a multistage cylinder or a sleeve cylinder, is specifically designed to provide an extended stroke length while maintaining a compact retracted length. In contrast, a standard hydraulic cylinder typically consists of a single-stage rod and barrel design. Here are the key differences between a telescopic cylinder and a standard hydraulic cylinder:

Despite these differences, both telescopic cylinders and standard hydraulic cylinders are essential components in hydraulic systems. They both rely on hydraulic fluid to generate force and provide linear motion. The selection of the cylinder type depends on the specific requirements of the application, including stroke length, retracted length, load capacity, and available space. It’s important to consult the manufacturer’s guidelines and specifications to ensure the proper selection, installation, and maintenance of the hydraulic cylinder based on the specific application requirements.

China Standard Big Telescopic Hydraulic Cylinder for Trailer vacuum pump adapterProduct Description

Big Telescopic Hydraulic Cylinder For TrailerProduct Description: Widely used in equipment for Engineering, Coal&mine, Agriculture and Environmental sanitation Big Telescopic Hydraulic Cylinder For Trailer used in engineering has high requirements for security performance, as it works frequently with large shock and vibration, so the requirements of reliability is high. Limit working condition bear large lateral load, so it has higher requirements for hardness and wear resistance. Product Display: Specifications:

Mounting Method: Our Factory: Inspection Process:

Packing & Delivery: Appliactions: Application: Mobile Cranes, Trailer, excavator, log splitter, hydraulic press, garbage compactor, lift platform, dock leveler About US: HangZhou GLORIA INDUSTRIAL TECH CO.,LTD. is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories. As a highly specialized manufacturer of hydraulic cylinders, CHINAMFG provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, GLIT can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality. If possible, when contact with us, please apply information as below

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes. And if you have samples, we can manufacture according to your samples after sending to us. Welcome to our factory if you have any time. Your satisfaction is our biggest motivation. Now, you can contact with us for any question or inquiry. FAQ: 1, What does your company do? /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can telescopic cylinders be repaired or maintained when necessary?Yes, telescopic cylinders can be repaired and maintained when necessary. Here’s a detailed explanation: Repairability: Telescopic cylinders are designed with repairability in mind. The modular construction of telescopic cylinders allows for individual components or stages to be replaced or repaired as needed. If a specific part of the cylinder becomes damaged or worn out, it can be disassembled and repaired or replaced, minimizing downtime and cost compared to replacing the entire cylinder. Maintenance: Maintenance is essential to ensure the optimal performance and longevity of telescopic cylinders. Regular maintenance practices may include:

Depending on the specific application and operating conditions, maintenance intervals and procedures may vary. It’s important to follow the manufacturer’s maintenance recommendations and guidelines for the telescopic cylinder to ensure effective maintenance practices. Professional expertise: Repairing and maintaining telescopic cylinders often require professional expertise. It is recommended to engage qualified technicians or service personnel with experience in hydraulic systems and telescopic cylinder repairs. They have the knowledge and tools necessary to accurately diagnose issues, perform repairs, and conduct maintenance tasks in a safe and efficient manner. Manufacturer support: Manufacturers of telescopic cylinders typically provide support for repair and maintenance. They may offer technical documentation, repair manuals, and access to replacement parts to facilitate the repair process. Consulting the manufacturer’s resources and seeking their assistance can ensure that repairs and maintenance are carried out correctly and in accordance with the cylinder’s specifications. By implementing proper repair and maintenance practices, telescopic cylinders can be kept in good working condition, extending their service life and maintaining reliable performance. It’s important to note that repair and maintenance should be performed by qualified individuals and comply with relevant safety guidelines and industry standards.

How do telescopic cylinders handle variations in hydraulic seal technology?Telescopic cylinders are designed to accommodate variations in hydraulic seal technology. Here’s a detailed explanation: Compatibility with different seal types: Telescopic cylinders are engineered to be compatible with various types of hydraulic seals available in the market. Whether it’s a standard O-ring seal, lip seal, V-ring seal, or any other seal design, the cylinder’s construction takes into account the requirements of different seal technologies. This compatibility ensures that telescopic cylinders can effectively handle variations in hydraulic seal technology. Seal retention and protection: Telescopic cylinders incorporate features to retain and protect hydraulic seals. The cylinder design includes seal grooves, seal retainers, or other mechanisms that securely hold the seals in place, preventing their displacement or damage during operation. This seal retention and protection mechanism ensures the longevity and effectiveness of the seals, regardless of the specific seal technology used. Seal lubrication and contamination prevention: Telescopic cylinders address the lubrication and contamination concerns associated with different seal technologies. The cylinder’s hydraulic system is designed to provide proper lubrication to the seals, ensuring smooth movement and reducing friction. Additionally, measures such as seal scrapers or wipers are implemented to prevent the ingress of contaminants, such as dust, dirt, or moisture, which could compromise the performance of the seals. These lubrication and contamination prevention mechanisms cater to the specific requirements of various seal technologies. Seal replacement and maintenance: Telescopic cylinders are designed to facilitate seal replacement and maintenance procedures. The cylinder construction allows for easy access to the seals, simplifying the replacement process when necessary. This feature is advantageous when dealing with different seal technologies, as it enables swift and efficient maintenance, regardless of the specific seal design being used. Adaptability to seal advancements: Telescopic cylinder designs often incorporate adaptability to advancements in hydraulic seal technology. Manufacturers continuously develop new seal technologies to improve performance, durability, and efficiency. Telescopic cylinders are designed with flexibility to accommodate future advancements, ensuring compatibility with emerging seal technologies and allowing for upgrade possibilities without significant modifications to the cylinder itself. Overall, telescopic cylinders are engineered to handle variations in hydraulic seal technology through compatibility with different seal types, seal retention and protection features, seal lubrication and contamination prevention mechanisms, ease of seal replacement and maintenance, and adaptability to seal advancements. These design considerations ensure that telescopic cylinders can effectively work with different seal technologies, providing reliable and efficient performance in hydraulic systems. It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the recommended seal types and maintenance practices for telescopic cylinders.

What is a telescopic cylinder and how does it work?A telescopic cylinder is a type of hydraulic cylinder that consists of multiple nested stages or sections that can extend and retract, similar to a telescope. Here’s a detailed explanation: A telescopic cylinder is primarily used when a long stroke length is required while maintaining a compact retracted length. It is commonly used in applications such as dump trucks, cranes, aerial platforms, and other equipment that require extended reach or height adjustment. Here’s how a telescopic cylinder works:

The use of telescopic cylinders offers several benefits:

Overall, a telescopic cylinder is a hydraulic cylinder with nested stages that can extend and retract, providing an extended stroke length while maintaining a compact retracted length. Its structure and operation make it ideal for applications requiring long reach or height adjustment. It’s important to follow the manufacturer’s guidelines and specifications for the telescopic cylinder, including proper maintenance and inspection, to ensure its safe and reliable operation.

China manufacturer Professional Tower Crane Spare Parts Telescopic Cage Hydraulic Cylinder vacuum pump beltProduct Description

Professional Tower Crane Spare Parts Telescopic Cage Hydraulic Cylinder Data Sheet

Product Description Product Characteristics

*Plated Chrome Piston Rod

*Automatic Welding

*#45 Steel

*Quality Test

——RELATED PRODUCTS——

HangZhou CHINAMFG Machinery Co., LTD., formerly known as HangZhou Xihu (West Lake) Dis.n East CHINAMFG Petrochemical Fitting Corporation, was founded in 1997. CHINAMFG focus on the field of machinery manufacturing, committed to providing cylinder, flange (petrochemical accessories), pin, sheet metal parts and other mechanical products; Heat exchanger, ambient vaporizer, LNG handling arm and other gas engineering products for domestic sales and foreign trade import and export services. CHINAMFG is a leading enterprise who collects production, foreign trade, sales and service. Relying on our technology, taking quality as the core and efficiency as the soul, we aim to bring the best quality mechanical products to our customers, and is committed to becoming a one-stop solution expert of mechanical parts. It is determined to become a one-stop service supplier integrating research and development, production and sales. Enterprises adhere to the “all for the customer” service purpose, implement the “customer first, quality first, service first” business philosophy, the use of omni-channel sales model, to build a global sales network, open CHINAMFG machinery brand development road. Aofa always follows the purpose of “providing value products for customers, providing development space for employees, and creating outstanding leading brands in the industry”, abides by the enterprise development concept of “creating value by heart”, and adheres to the mission of “manufacturing machinery high-quality products, creating a harmonious society”. The enterprise gathers many young and promising, positive people with lofty ideals, through the perfect management system and competitive incentive mechanism, aims to provide all-round development space for employees, and create a better future with the enterprise. Scientific management mode, intimate service attitude, for the enterprise to win credibility and public praise. In the fierce market competition to establish a good corporate image, and with many enterprises to establish long-term, stable strategic partnership, for the further development of the enterprise has laid a CHINAMFG foundation. Q1:Can you provide a sample before a big order? Q2:Are you able to make Non-standard or customized air cylinders? Q3:How long is the warranty? Q4:Can I have my brand on the products? Q5:What is your delivery time? Q6. Do you test all your goods before delivery?

Can telescopic cylinders be used in construction equipment like cranes?Yes, telescopic cylinders are commonly used in construction equipment, including cranes. Here’s a detailed explanation: Role in crane operation: Telescopic cylinders play a critical role in the operation of cranes by enabling the extension and retraction of crane booms or arms. The telescopic cylinder is typically located at the base of the boom and is responsible for extending or retracting the boom sections, allowing the crane to reach different heights and distances. Extension and retraction mechanism: The telescopic cylinder in a crane consists of multiple stages or sleeves that retract inside one another. This nested design allows for compact storage when the boom is retracted, minimizing the overall length of the crane. When the cylinder extends, the stages slide out, increasing the length of the boom and providing the necessary reach. The synchronized extension and retraction of the stages are facilitated by the hydraulic control system. Hydraulic control system: The hydraulic control system in cranes is responsible for the precise and controlled extension and retraction of telescopic cylinders. It regulates the flow of hydraulic fluid to each stage of the cylinder, ensuring synchronized movement. By adjusting the flow rate, the operator can control the speed of extension and retraction, allowing for smooth and controlled operation of the crane. Load handling capabilities: Telescopic cylinders in cranes are designed to handle significant loads. They provide the necessary lifting force to support heavy loads at various boom lengths. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and to deliver the required lifting capacities. Variety of crane types: Telescopic cylinders are utilized in various types of cranes, including mobile cranes, truck-mounted cranes, and crawler cranes. These cranes are widely used in construction sites, infrastructure projects, and other lifting and material handling applications. The versatility of telescopic cylinders allows them to be integrated into different crane designs and configurations. Advantages of telescopic cylinders in cranes: Telescopic cylinders offer several advantages in crane applications. These include:

Overall, telescopic cylinders are integral components of construction equipment like cranes. They enable the extension and retraction of crane booms, contribute to efficient and controlled operation, and enhance the lifting capabilities of cranes in various construction and material handling tasks. It’s important to consult the crane manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

How do telescopic cylinders handle variations in hydraulic seal technology?Telescopic cylinders are designed to accommodate variations in hydraulic seal technology. Here’s a detailed explanation: Compatibility with different seal types: Telescopic cylinders are engineered to be compatible with various types of hydraulic seals available in the market. Whether it’s a standard O-ring seal, lip seal, V-ring seal, or any other seal design, the cylinder’s construction takes into account the requirements of different seal technologies. This compatibility ensures that telescopic cylinders can effectively handle variations in hydraulic seal technology. Seal retention and protection: Telescopic cylinders incorporate features to retain and protect hydraulic seals. The cylinder design includes seal grooves, seal retainers, or other mechanisms that securely hold the seals in place, preventing their displacement or damage during operation. This seal retention and protection mechanism ensures the longevity and effectiveness of the seals, regardless of the specific seal technology used. Seal lubrication and contamination prevention: Telescopic cylinders address the lubrication and contamination concerns associated with different seal technologies. The cylinder’s hydraulic system is designed to provide proper lubrication to the seals, ensuring smooth movement and reducing friction. Additionally, measures such as seal scrapers or wipers are implemented to prevent the ingress of contaminants, such as dust, dirt, or moisture, which could compromise the performance of the seals. These lubrication and contamination prevention mechanisms cater to the specific requirements of various seal technologies. Seal replacement and maintenance: Telescopic cylinders are designed to facilitate seal replacement and maintenance procedures. The cylinder construction allows for easy access to the seals, simplifying the replacement process when necessary. This feature is advantageous when dealing with different seal technologies, as it enables swift and efficient maintenance, regardless of the specific seal design being used. Adaptability to seal advancements: Telescopic cylinder designs often incorporate adaptability to advancements in hydraulic seal technology. Manufacturers continuously develop new seal technologies to improve performance, durability, and efficiency. Telescopic cylinders are designed with flexibility to accommodate future advancements, ensuring compatibility with emerging seal technologies and allowing for upgrade possibilities without significant modifications to the cylinder itself. Overall, telescopic cylinders are engineered to handle variations in hydraulic seal technology through compatibility with different seal types, seal retention and protection features, seal lubrication and contamination prevention mechanisms, ease of seal replacement and maintenance, and adaptability to seal advancements. These design considerations ensure that telescopic cylinders can effectively work with different seal technologies, providing reliable and efficient performance in hydraulic systems. It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the recommended seal types and maintenance practices for telescopic cylinders.

What industries commonly use telescopic cylinders in their applications?Telescopic cylinders find applications in a wide range of industries where extended reach, height adjustment, or lifting capabilities are required. Here’s a detailed explanation: Industries commonly using telescopic cylinders:

These are just a few examples of industries that commonly use telescopic cylinders in their applications. The versatility and efficiency of telescopic cylinders make them valuable components in numerous sectors where extended stroke lengths or compact retracted lengths are required. It’s important to consult industry-specific guidelines and regulations to ensure the proper selection, installation, and maintenance of telescopic cylinders based on the specific application requirements.

China supplier Single Acting CZPT Type Telescopic Hydraulic Cylinder for Dumper Trailer on Sale vacuum pump diyProduct Description

Product description: FC telescopic front-end cylinders are primarily designed for straight headboard dump trucks with a capacity range of over 100 tons tipping weight. Our trunnion type FC cylinder is lightweight, strong, maintenance free and offers the most added stability to the tipper. The CHINAMFG brand FC tipping cylinders have earned reputation for their reliability and value for money over many years. Designed for Dump Truck applications, FC series cylinder with 3-7 stages is capable of lifting more weight which in return allows trucks to be equipped with smaller cylinders reducing space and saving weight. This CHINAMFG series cylinder is mostly used in combination with a Straight Headboard Type and Trunnion Type Body Connection. Workshop with advanced equipment:

Exhibition:

Certificates: ISO9001, IATF 16949:2016, CE,etc.

FAQ: Q2: What’s your cylinder’s advantages ? Q3: When your company be established ? Q4: How about the delivery time ? Q5: How about the cylinder’s quality gurantee ? /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What safety considerations are important when using machinery with telescopic cylinders?When using machinery with telescopic cylinders, several safety considerations should be taken into account. Here’s a detailed explanation: Operator training and awareness: Proper training and awareness are crucial for operators working with machinery equipped with telescopic cylinders. Operators should receive comprehensive training on the safe operation of the machinery, including the correct use of telescopic cylinders. They should be familiar with the controls, safety features, and best practices to ensure their own safety and the safety of others in the vicinity. Regular inspection and maintenance: Regular inspection and maintenance of telescopic cylinders are essential for ensuring safe operation. Cylinders should be inspected for signs of wear, damage, or leakage. Any issues should be addressed promptly to prevent potential failures or accidents. Lubrication, if required, should be performed according to the manufacturer’s recommendations. Proper load capacity and stability: It is important to ensure that the machinery and telescopic cylinders are used within their specified load capacity. Exceeding the load capacity can lead to instability, loss of control, or structural failure. Proper weight distribution and secure attachment of loads are also critical to maintaining stability during operation. Safe work environment: Creating a safe work environment is essential when using machinery with telescopic cylinders. This includes maintaining clear and unobstructed pathways for the machinery’s movement, removing potential hazards, and implementing appropriate safety measures such as barriers, signage, or warning systems to prevent unauthorized access or accidental contact with the machinery or its cylinders. Emergency stop and shutdown procedures: Emergency stop and shutdown procedures should be clearly communicated to operators. They should be trained on how to quickly and effectively stop the machinery’s operation in case of an emergency or when a safety hazard is detected. These procedures should be regularly reviewed and practiced to ensure a prompt response in critical situations. Proper guarding and protection: Telescopic cylinders should be adequately guarded to prevent accidental contact and potential injuries. Guarding may include physical barriers, shields, or sensors that detect the presence of personnel or objects in the cylinder’s path. Additionally, operators should wear appropriate personal protective equipment (PPE) as recommended for the specific task and working environment. Compliance with regulations and standards: It is important to ensure compliance with relevant regulations and safety standards when using machinery with telescopic cylinders. These regulations and standards may address aspects such as design, installation, operation, maintenance, and inspection of the machinery and its components. Adhering to these requirements helps mitigate risks and promotes a safe working environment. Regular risk assessments: Regular risk assessments should be conducted to identify and address potential hazards associated with the machinery and telescopic cylinders. This includes assessing risks related to operation, maintenance, equipment failure, environmental conditions, and human factors. Mitigation measures should be implemented based on the findings of the risk assessment. Overall, safety considerations when using machinery with telescopic cylinders involve operator training, regular inspection and maintenance, load capacity and stability, safe work environment, emergency procedures, guarding and protection, compliance with regulations, and regular risk assessments. By addressing these considerations, the risks associated with operating machinery with telescopic cylinders can be minimized, promoting a safer working environment. It’s important to consult the machinery manufacturer’s guidelines, safety manuals, and applicable regulations to ensure comprehensive understanding and implementation of safety practices.

Can telescopic cylinders be used in forestry equipment for tree handling?Yes, telescopic cylinders are commonly used in forestry equipment for tree handling tasks. Here’s a detailed explanation: Tree felling and extraction: Telescopic cylinders play a vital role in tree felling and extraction operations. They are utilized in equipment such as feller bunchers, harvesters, and forwarders. Telescopic cylinders provide the necessary force to cut down trees and extract them from the forest. The cylinders are used in combination with cutting heads, grapples, or clamps to grip, hold, and manipulate trees during the felling and extraction processes. Boom and arm extension: In forestry equipment, telescopic cylinders are employed to extend the booms and arms of machinery. This extension capability allows operators to reach trees located at various distances and heights, facilitating efficient tree handling. Telescopic cylinders enable the equipment to adapt to different tree sizes and positions, enhancing productivity and reducing manual labor. Precise control: Telescopic cylinders provide precise control over tree handling movements. The hydraulic control system allows operators to extend and retract the cylinders with accuracy, enabling controlled positioning of trees during felling, extraction, or stacking. This precise control is crucial for ensuring operator safety, preventing damage to the equipment or surrounding environment, and optimizing operational efficiency. Load handling and stacking: Telescopic cylinders support load handling and stacking operations in forestry equipment. They provide the necessary lifting force to handle tree logs and facilitate stacking for transportation or processing. The cylinders work in conjunction with grapples, forks, or other attachments to securely grip and manipulate tree logs during loading, unloading, or stacking activities. Stability and balance: Telescopic cylinders contribute to the stability and balance of forestry equipment during tree handling tasks. The controlled extension and retraction of the cylinders help maintain the proper weight distribution and prevent tipping or imbalance when handling heavy tree logs. This ensures the safety of operators and equipment in challenging forestry environments. Advantages of telescopic cylinders in forestry equipment: Telescopic cylinders offer several advantages in tree handling applications:

Overall, telescopic cylinders are widely used in forestry equipment for tree handling tasks, offering extended reach, precise control, efficient load handling, adaptability, and stability. They enhance the productivity, safety, and efficiency of forestry operations. It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in forestry equipment.

How does a telescopic cylinder handle variations in extension and retraction?A telescopic cylinder is designed to handle variations in extension and retraction through its inherent structure and hydraulic system. Here’s a detailed explanation: Handling variations in extension: When extending a telescopic cylinder, each stage or sleeve extends successively, one inside the other, to achieve the desired stroke length. This nested structure allows for incremental extension, providing flexibility in adapting to different extension requirements. The hydraulic system supplies pressurized fluid to each stage’s piston, generating the necessary force for extension. The internal flow paths in the cylinder ensure synchronized movement of the stages, allowing for controlled and precise extension. Handling variations in retraction: During retraction, the telescopic cylinder stages retract in the reverse order of extension. The hydraulic system controls the flow of fluid to each stage, allowing for controlled retraction. The nested structure of the cylinder ensures that each stage retracts smoothly inside the preceding stage. The hydraulic pressure and flow are regulated to prevent rapid or uncontrolled retraction, ensuring safe and stable operation. Compensating for variations: Telescopic cylinders are designed to compensate for variations in extension and retraction through their hydraulic control systems. The hydraulic system can be adjusted to vary the flow rate, pressure, or force applied to each stage, allowing for fine-tuning and accommodating different extension and retraction requirements. Additionally, the locking mechanisms incorporated in telescopic cylinders help maintain the extended position securely, compensating for external forces or variations in loads. Overall, the nested structure, hydraulic system, and locking mechanisms of telescopic cylinders provide the necessary flexibility and control to handle variations in extension and retraction. This enables the cylinders to adapt to different operating conditions, loads, and stroke length requirements in various applications. It’s important to follow the manufacturer’s guidelines and recommendations for proper operation, maintenance, and adjustment of telescopic cylinders to ensure their reliable and safe performance.

China factory Custom Non Standard Hydraulic Cylinder for Agricultural Machinery vacuum pump designProduct Description

Custom Non Standard Hydraulic Cylinder for Agricultural MachineryProduct Description Factory Design Customized Hydraulic Cylinder characteristics: Assemble with imported seals kits of NOK, Hallite and other brands to bring the better seal slick and the stronger persistence. Process with the advanced technology by CNC machine tools, automatic plating and painting equipments to ensure all the parts to have the lower surface roughness and the higher performance level. Own advanced special buffer device with independent intellectual property rights which can effectively absorb the shock to protect the cylinder work smoothly and reliable in performance. Specifications

Application Hydraulic Cylinder Product Application Nolanse’s quality custom products are produced for OEM applications in a wide variety of CHINAMFG industries, including manufacturing engineering machinery, loaders hydraulic cylinders, vehicle cylinders, construction, forestry, waste management, mining, material handling, industrial applications, agriculture, manufacturing, transportation, marine applications and oil field equipment. Our success has been built on the engineering expertise and manufacturing capabilities we offer to meet the very specific demands of our industry clients. Why Choose Us 1. Product Research & Development Nolanse builds quality products that are developed with use in mind. We specialize in working with every customer to share ideas and gather critical information regarding hydraulic cylinder fit and performance requirements for your specific application. This is accomplished by establishing a very close technical rapport with each customer and their engineering, purchasing and R&D departments – the experts in your organization who know best what functionality, quality, size and cylinders characteristics are critical to your equipment. If our standard lines don’t suit your application, CHINAMFG has extensive experience in custom hydraulic cylinder designs. We strive to develop dynamic, innovative and dependable hydraulic and machining solutions that exceed your expectations.

2. Hydraulic Cylinder Production We have the advanced CNC machine tools, a horizontal machining center, a welding robot, parts cleaning agent, automatic assembly lines, automatic painting equipment etc. to hydraulic cylinder ensure a 360-degree quality control of the production process. 3. Hydraulic Cylinder Product Testing We check all of the products, using fully equipped facilities and advanced instruments, regarding the performance, structure, size tolerance, roughness, hardness, pressure and sealing to ensure the hydraulic cylinder quality meets the requirements of our different customers. 4.Hydraulic Cylinder Product Certifications Nolanse is ISO 9001 registered for the design and manufacture of hydraulic cylinders and precision machining. 5. Professional Hydraulic Cylinder Team NOLANSE professional hydraulic cylinder team deeply understands the requirements and the technological advancement hydraulic ram. NOLANSE has been specialized in custom hydraulic cylinder development, manufacturing, sales, sample verification, order processing and product delivery, etc. NOLANSE is always working hard with passion to put our efforts to hydraulic cylinder technology and application. Company Information As a leader in hydraulic cylinder Design, Manufacturing and Custom Machining for over 36 years, NOLANSE has its own over 220 employees and over 55,000 square CHINAMFG manufacturing factories. We have professional departments including hydraulic cylinder design, sales, production, quality control department, etc. NOLANSE hydraulic cylinder products mainly include manufacturing engineering machinery,loaders hydraulic cylinders,vehicle cylinders,hydraulic systems and air controlling systems.It can also manufacture large-scale,non-standard and different stypes of cylinders, etc. All our hydraulic cylinder are manufactured from high quality raw materials with strict professional process and quality assurance. We had been worked hard and invested more to become the leader in hydraulic cylinder industry. Our partners are those famous hydraulic cylinder brands from America, Canada, Australia, Germany, England and other European Countries. Product quality, shorter delivery time and customer satisfaction are our long term commitment to our CHINAMFG customers. Hope to be your partner. Nolanse’s name has become synonymous with quality, on time delivery and exceptional service. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

How do hydraulic cylinders handle variations in temperature and harsh operating environments?Hydraulic cylinders are designed to handle variations in temperature and harsh operating environments by incorporating specific features and materials that ensure their durability, reliability, and performance. The ability of hydraulic cylinders to withstand extreme temperatures, corrosive environments, and other harsh conditions is crucial for their successful operation in a wide range of applications. Here’s a detailed explanation of how hydraulic cylinders handle variations in temperature and harsh operating environments: 1. Temperature Range: – Hydraulic cylinders are designed to operate within a specified temperature range. The materials used in their construction, such as cylinder barrels, pistons, seals, and lubricants, are selected to withstand the anticipated temperature variations. Specialized seals and O-rings made from materials like nitrile, Viton, or polyurethane are used to maintain their sealing properties over a wide temperature range. Heat-resistant coatings or thermal insulation may be applied to certain components to protect them from high temperatures. 2. Thermal Expansion: – Hydraulic cylinders are designed to accommodate thermal expansion and contraction that occurs with temperature changes. The materials used in their construction have different coefficients of thermal expansion, allowing the cylinder components to expand or contract at a similar rate. This design consideration prevents excessive stress, binding, or leakage that could result from thermal expansion or contraction. 3. Heat Dissipation: – In applications where hydraulic cylinders are subjected to high temperatures, heat dissipation mechanisms are employed to prevent overheating. Cooling fins or heat sinks may be incorporated into the cylinder design to increase the surface area for heat transfer. In some cases, external cooling methods such as air or liquid cooling systems can be used to maintain optimal operating temperatures. 4. Corrosion Resistance: – Hydraulic cylinders used in harsh operating environments are constructed from materials that exhibit excellent corrosion resistance. Stainless steel, chrome-plated steel, or other corrosion-resistant alloys are commonly used for cylinder components exposed to corrosive substances or environments. Additionally, surface treatments such as coatings, plating, or specialized paints can provide an extra layer of protection against corrosion. 5. Sealing Systems: – Hydraulic cylinders employ sealing systems that are specifically designed to withstand harsh operating environments. The seals used in hydraulic cylinders are selected based on their resistance to temperature extremes, chemicals, abrasion, and other environmental factors. Specialized seal designs, such as wiper seals, rod seals, or high-temperature seals, are utilized to maintain effective sealing and prevent contamination of the hydraulic fluid. 6. Lubrication: – Proper lubrication is essential for the smooth operation and longevity of hydraulic cylinders, particularly in harsh operating environments. Lubricants are selected based on their ability to withstand high temperatures, resist oxidation, and provide effective lubrication under extreme conditions. Regular maintenance and lubrication practices ensure that the cylinder components continue to operate smoothly and reduce the effects of wear and friction. 7. Robust Construction: – Hydraulic cylinders designed for harsh operating environments are built with robust construction techniques to withstand the rigors of such conditions. The cylinder barrels, rods, and other components are manufactured to meet strict quality and durability standards. Welded or bolted construction methods are employed to ensure the structural integrity of the cylinders. Reinforcements, such as flanges or tie rods, may be added to enhance the cylinder’s strength and resistance to external forces. 8. Environmental Protection: – Hydraulic cylinders can be equipped with additional protective features to shield them from harsh operating environments. Protective covers, boots, or bellows can be used to prevent contaminants, debris, or moisture from entering the cylinder and compromising its performance. These protective measures help extend the service life of hydraulic cylinders in demanding conditions. 9. Compliance with Standards: – Hydraulic cylinders manufactured for specific industries or applications often comply with industry standards or regulations related to operating temperature ranges, environmental conditions, or safety requirements. Compliance with these standards ensures that hydraulic cylinders are designed and tested to meet the specific demands of their intended operating environments. In summary, hydraulic cylinders are designed to handle variations in temperature and harsh operating environments by incorporating suitable materials, thermal expansion considerations, heat dissipation mechanisms, corrosion-resistant components, specialized sealing systems, proper lubrication, robust construction techniques, protective features, and compliance with industry standards. These design considerations and features enable hydraulic cylinders to operate reliably and effectively in a wide range of demanding applications and environmental conditions.

Ensuring Controlled and Safe Force Application in Heavy Machinery with Hydraulic CylindersHydraulic cylinders play a critical role in heavy machinery by ensuring controlled and safe force application. The ability to exert and control high forces is essential for heavy machinery operations, such as lifting, pressing, pushing, or pulling heavy loads. Let’s explore how hydraulic cylinders ensure controlled and safe force application in heavy machinery:

In summary, hydraulic cylinders ensure controlled and safe force application in heavy machinery through force control, load balancing, safety valves, pressure relief systems, and robust structural design. These features and design considerations enable operators to exert the necessary force while maintaining safety and preventing excessive loads or force surges. By incorporating hydraulic cylinders into heavy machinery, manufacturers can achieve controlled force application, enhance operational safety, and protect the machinery from damage or failure.

What benefits do hydraulic cylinders offer for tasks requiring heavy lifting or movement?Hydraulic cylinders offer numerous benefits for tasks that involve heavy lifting or movement. Their unique design and characteristics make them well-suited for applications that require substantial force, precise control, and reliable operation. Here are the detailed benefits that hydraulic cylinders provide for such tasks: 1. High Force Generation: – Hydraulic cylinders are capable of generating significant amounts of force. By utilizing hydraulic pressure, which can be easily amplified, hydraulic cylinders can exert substantial force to lift and move heavy loads. The force output of a hydraulic cylinder is directly proportional to the hydraulic pressure and the surface area of the piston. This high force capability makes hydraulic cylinders ideal for tasks that involve heavy lifting, pushing, or pulling. 2. Precise Control: – Hydraulic cylinders offer precise control over the force and motion they generate. By regulating the flow of hydraulic fluid into the cylinder, the speed, direction, and position of the cylinder’s movement can be accurately controlled. This level of control is crucial for tasks that require precise positioning, delicate movements, or synchronization of multiple cylinders. It enables operators to perform operations with accuracy and minimize the risk of damage or accidents. 3. Safety: – Hydraulic cylinders are designed with safety features to ensure the protection of both personnel and equipment. They incorporate overload protection mechanisms, such as relief valves, that prevent excessive force or pressure from damaging the system. Additionally, hydraulic cylinders allow for controlled and gradual movements, reducing the risk of sudden and uncontrolled motions that could pose safety hazards during heavy lifting or movement tasks. 4. Versatility and Adaptability: – Hydraulic cylinders are versatile components that can be adapted to meet specific requirements. They can be customized based on factors such as force capacity, stroke length, speed, and mounting options, allowing them to be integrated into various types of machinery. This versatility makes hydraulic cylinders suitable for a wide range of applications, including construction, material handling, mining, agriculture, and more. 5. Smooth and Controlled Operation: – Hydraulic cylinders provide smooth and controlled operation, ensuring efficient and reliable performance during heavy lifting or movement tasks. The hydraulic fluid acts as a cushioning medium, which helps dampen shocks and vibrations, resulting in smoother and quieter operation. This controlled operation also reduces the risk of damage to the load being lifted or the surrounding equipment. 6. Compact Design: – Hydraulic cylinders offer a high power-to-size ratio, allowing for compact machinery design. Their relatively small size, compared to the forces they can generate, makes them suitable for applications where space is limited or weight restrictions apply. This compact design enables the integration of hydraulic cylinders into different types of equipment without compromising performance or efficiency. 7. Durability and Reliability: – Hydraulic cylinders are built to withstand rigorous operating conditions and provide long-term reliability. They are constructed with robust materials, precise machining, and effective sealing systems to ensure durability and prevent fluid leakage. Hydraulic cylinders can withstand high pressures, heavy loads, and continuous use, making them suitable for demanding tasks involving heavy lifting or movement. 8. Energy Efficiency: – Hydraulic cylinders contribute to energy efficiency in tasks requiring heavy lifting or movement. Hydraulic systems allow for the transfer of power over long distances without significant power losses. Additionally, hydraulic cylinders can incorporate energy-saving features such as load-sensing technology and regenerative circuits, which reduce energy consumption by optimizing the use of hydraulic fluid. In summary, hydraulic cylinders offer several benefits for tasks that involve heavy lifting or movement. They provide high force generation, precise control, safety features, versatility, smooth operation, compact design, durability, and energy efficiency. These advantages make hydraulic cylinders indispensable components in various industries where heavy loads need to be lifted, pushed, or moved with accuracy and reliability.

China Best Sales Tianjian Piston Type by Plywood Case Scissor Lift Cylinders Hydraulic Oil Cylinder vacuum pump engineProduct Description

China Factory Produce Double Acting Piston Rod Ultra-High Press Cylinder for Filter Press Made in ChinaProduct Specifications :

Product Display:

Compact structural design, high-strength material use, and special heat treatment and welding processes ensure that the oil cylinder has extremely high fatigue durability under high pressure and heavy load. The hydraulic cylinder adopts a multi-channel sealing design to ensure stable operation of the sealing system. Designed with a wide temperature resistance range (-25 ºC to+120 ºC), and able to provide customized services for higher or lower temperature oil cylinders. The inner hole of the guide sleeve adopts a high load-bearing guide structure to maximize the lateral load resistance of the oil cylinder. The surface of the piston rod adopts special surface treatment to ensure excellent wear and corrosion resistance of the piston rod. Work pressure, size specifications, installation methods, etc. can be customized according to customer needs for design.

Our Factory:

Inspection of Mechanical Properties of Raw Materials

About US: ZheJiang Tianjian Hydraulic Technology Co.,Ltd is specializing in the production of various types of hydraulic cylinders as well as cylinder barrel, piston cylinder and other cylinder accessories. As a highly specialized manufacturer of hydraulic cylinders, tianjian provides design optimization solutions and reliable products to many customers at home and abroad. No matter in construction machinery, railway bridge machinery, port ship machinery, metallurgy and mining machinery, oil and light industry machinery, special vehicles and other industries, tianjian can provide various standard and non-standard hydraulic cylinder design optimization schemes and products according to users’ requirements, and provide integrated services for perfection and quality. If possible, when contact with us, please apply information as below

Or you can offer us your sketch diagram or photos so that we could understand you exactly meaning, help us avoid mistakes. And if you have samples, we can manufacture according to your samples after sending to us. Welcome to our factory if you have any time. Your satisfaction is our biggest motivation. Our Main Customers Now, you can contact with us for any question or inquiry. FAQ: 1, What does your company do? /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1