Product Description

Product Description

Quick details

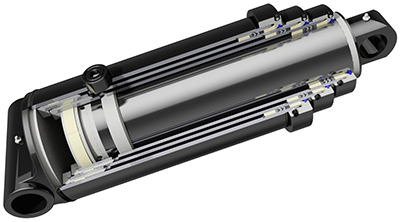

Gland —-High grade ductile iron

Tube —–Cold drawn honed tubling

Piston—–High grade ductile iron

Piston rod—-Chromed C45

Piston seal—-Urethane seal

End cap—-Casting seel

Mounting style—-Pins and clips included

Gland seals—-Polyurethane U-cup

Rod wiper—-Urethane snap in

Paint color—-Semi-gloss black, grey, red

1.Light-weight,high strength

Base on the nature of construction work,the hydraulic cylinders need to suit for high strength,high

using frequency,high fatigability.to promise the sability and reliablity of application.

2.the seal system

select the excellent seal kits from japan and germany.adopt the advanced physical design,make

sure the hydraulic cylinder get the best piston rod oil film

3.cylinder body

adopt the good-quality alloy honed tube,though cold-drawing and rolling,to reach an excellent

toughness and surface hardness.improve the wear-resistance.

4.piston rod

middle frequency induction hardening and tempering,chrome plated on rod surface to improve the

anti-rust ,wear-resistance and anti-scratch property.

5.safety/cushioning fuction

The inside of cylinder set up an cushioning device in the end of stroke,it can absorb the juge inpact.

Technical Specification size.

|

cylinder diameter (mm) |

piston rod diameter (mm) |

max stroke (mm) |

||

|

40 |

20 |

22 |

25 |

500 |

|

50 |

25 |

28 |

32 |

600 |

|

63 |

32 |

35 |

45 |

800 |

|

80 |

40 |

45 |

55 |

2000 |

|

90 |

45 |

50 |

63 |

2000 |

|

100 |

50 |

55 |

70 |

4000 |

|

110 |

55 |

63 |

80 |

4000 |

|

125 |

63 |

70 |

90 |

4000 |

|

140 |

70 |

80 |

100 |

4000 |

|

150 |

75 |

85 |

105 |

4000 |

|

160 |

80 |

90 |

110 |

4000 |

|

180 |

90 |

100 |

125 |

4000 |

|

200 |

100 |

110 |

140 |

4000 |

|

220 |

110 |

125 |

160 |

4000 |

|

250 |

125 |

140 |

180 |

4000 |

Cylinder tube machining

Piston

Application boom cylider, stick cylinder, Dozer cylinder.

| Excavator Type | Name | Stroke (mm) | Installation Diameter(mm) | Cylinder Diameter(mm) | Rod Diameter(mm) |

| 5.5T | Boom Cylinder | 710 | 1120 | 115 | 65 |

| Stick Cylinder | 815 | 1210 | 90 | 55 | |

| Bucket Cylinder | 605 | 945 | 85 | 55 | |

| Dozer Cylinder | 150 | 500 | 110 | 60 | |

| 6.5T | Boom Cylinder | 885 | 1311 | 110 | 65 |

| Stick Cylinder | 900 | 1300 | 90 | 60 | |

| Bucket Cylinder | 730 | 1120 | 80 | 50 | |

| Dozer Cylinder | 145 | 565 | 130 | 70 | |

| 11.5T | Left Boom Cylinder | 980 | 1480 | 100 | 70 |

| Right Boom Cylinder | 980 | 1480 | 100 | 70 | |

| Stick Cylinder | 1571 | 1530 | 115 | 80 | |

| Bucket Cylinder | 885 | 1375 | 95 | 65 | |

| 18.5T | Left Boom Cylinder | 1195 | 1790 | 120 | 85 |

| Right Boom Cylinder | 1195 | 1790 | 120 | 85 | |

| Stick Cylinder | 1405 | 2000 | 130 | 95 | |

| Bucket Cylinder | 1110 | 1630 | 110 | 80 | |

| 20T | Boom Cylinder | 1285 | 1870 | 120 | 85 |

| Stick Cylinder | 1490 | 2075 | 135 | 95 | |

| Bucket Cylinder | 1120 | 1680 | 115 | 80 | |

| 23T | Boom Cylinder Assembly | 1295 | 1870 | 130 | 90 |

| Stick Cylinder Assembly | 1675 | 2225 | 140 | 100 | |

| Bucket Cylinder Assembly | 1156 | 1744 | 130 | 90 | |

| 26T | Boom Cylinder Assembly | 1420 | 1980 | 139 | 100 |

| Stick Cylinder Assembly | 1748 | 2348 | 149 | 110 | |

| Bucket Cylinder Assembly | 1130 | 1753 | 134 | 100 | |

| 40T | Boom Cylinder Assembly | 1495 | 2135 | 160 | 110 |

| Stick Cylinder Assembly | 1790 | 2480 | 170 | 110 | |

| Bucket Cylinder Assembly | 1285 | 1990 | 160 | 110 |

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment 30%TT in advance. 70% T/T before shippment

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Switching Type |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can telescopic cylinders be used in construction equipment like cranes?

Yes, telescopic cylinders are commonly used in construction equipment, including cranes. Here’s a detailed explanation:

Role in crane operation:

Telescopic cylinders play a critical role in the operation of cranes by enabling the extension and retraction of crane booms or arms. The telescopic cylinder is typically located at the base of the boom and is responsible for extending or retracting the boom sections, allowing the crane to reach different heights and distances.

Extension and retraction mechanism:

The telescopic cylinder in a crane consists of multiple stages or sleeves that retract inside one another. This nested design allows for compact storage when the boom is retracted, minimizing the overall length of the crane. When the cylinder extends, the stages slide out, increasing the length of the boom and providing the necessary reach. The synchronized extension and retraction of the stages are facilitated by the hydraulic control system.

Hydraulic control system:

The hydraulic control system in cranes is responsible for the precise and controlled extension and retraction of telescopic cylinders. It regulates the flow of hydraulic fluid to each stage of the cylinder, ensuring synchronized movement. By adjusting the flow rate, the operator can control the speed of extension and retraction, allowing for smooth and controlled operation of the crane.

Load handling capabilities:

Telescopic cylinders in cranes are designed to handle significant loads. They provide the necessary lifting force to support heavy loads at various boom lengths. The cylinder’s bore size, rod diameter, and overall construction are engineered to withstand the forces exerted during lifting and to deliver the required lifting capacities.

Variety of crane types:

Telescopic cylinders are utilized in various types of cranes, including mobile cranes, truck-mounted cranes, and crawler cranes. These cranes are widely used in construction sites, infrastructure projects, and other lifting and material handling applications. The versatility of telescopic cylinders allows them to be integrated into different crane designs and configurations.

Advantages of telescopic cylinders in cranes:

Telescopic cylinders offer several advantages in crane applications. These include:

- Compactness: Telescopic cylinders enable the boom to be retracted to a compact size, making it easier to transport and maneuver the crane in confined spaces.

- Reach and height capabilities: The telescopic design allows the crane to achieve extended reach and height, enabling it to access elevated work areas or reach over obstacles.

- Efficiency: The controlled extension and retraction of telescopic cylinders contribute to efficient operation, allowing the crane to adjust its boom length quickly and precisely.

- Stability: Telescopic cylinders provide stability to the crane by supporting the boom and load, ensuring safe lifting and lowering of heavy objects.

Overall, telescopic cylinders are integral components of construction equipment like cranes. They enable the extension and retraction of crane booms, contribute to efficient and controlled operation, and enhance the lifting capabilities of cranes in various construction and material handling tasks.

It’s important to consult the crane manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, maintenance requirements, and safety considerations.

Can telescopic cylinders be used in mining equipment for material transport?

Yes, telescopic cylinders are commonly used in mining equipment for material transport tasks. Here’s a detailed explanation:

Material loading and unloading:

Telescopic cylinders play a crucial role in loading and unloading materials in mining operations. They are utilized in equipment such as wheel loaders, excavators, and dump trucks. Telescopic cylinders enable the lifting and lowering of buckets, forks, or other material handling attachments, facilitating efficient material transport.

Extended reach:

In mining equipment, telescopic cylinders offer extended reach capabilities. This allows operators to access materials located at various distances, heights, or depths. The telescopic design of the cylinders enables them to extend and retract, providing the necessary reach for loading and unloading materials in mining applications.

Precise control:

Telescopic cylinders provide precise control over material transport movements. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, allowing operators to achieve accurate positioning and controlled movements during loading, unloading, and material placement. This precise control is essential for optimizing productivity and safety in mining operations.

Load handling capacity:

Telescopic cylinders are designed to handle heavy loads encountered in mining environments. They provide the necessary lifting force to transport large volumes of materials, such as ore, rocks, or overburden. The cylinders are engineered to withstand the demanding conditions of mining operations and ensure safe and efficient load handling.

Adaptability to terrain:

Mining equipment operates in diverse terrains, including uneven surfaces or steep inclines. Telescopic cylinders offer adaptability to varying terrain conditions. The extended reach and controlled movements provided by the cylinders allow operators to navigate challenging terrains and transport materials efficiently in mining sites.

Support for attachments:

Telescopic cylinders often support a range of attachments or tools that enhance material transport capabilities in mining equipment. For example, in wheel loaders, telescopic cylinders are used to extend the lifting arms, while different attachments such as buckets or forks facilitate the handling of various materials.

Advantages of telescopic cylinders in mining equipment:

Telescopic cylinders offer several advantages in material transport applications within mining:

- Extended reach: Telescopic cylinders enable operators to access materials located at varying distances or depths.

- Precise control: The hydraulic control system allows for accurate positioning and controlled movements, enhancing productivity and safety.

- Heavy-load handling: Telescopic cylinders provide the necessary lifting force to transport large volumes of materials encountered in mining operations.

- Adaptability to terrain: The extended reach and controlled movements of telescopic cylinders facilitate material transport in diverse mining terrains.

- Support for attachments: Telescopic cylinders can be used in conjunction with attachments or tools that enhance material handling capabilities in mining equipment.

Overall, telescopic cylinders are widely used in mining equipment for material transport tasks, offering extended reach, precise control, load handling capacity, adaptability to terrain, and support for attachments. They contribute to the efficiency, productivity, and safety of material transport operations in mining.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in mining equipment.

Can telescopic cylinders be customized for specific machinery and equipment?

Yes, telescopic cylinders can be customized to meet the specific requirements of different machinery and equipment. Here’s a detailed explanation:

Customizable stroke length:

Telescopic cylinders can be designed and manufactured with customized stroke lengths to suit the specific needs of machinery and equipment. The stroke length determines the maximum extension or retraction distance of the cylinder and can be tailored to match the required range of motion for a particular application.

Adjustable force and speed:

The hydraulic control system of telescopic cylinders allows for adjustability in terms of force and speed. The system can be configured to provide the necessary force output for the machinery or equipment, ensuring optimal performance. Additionally, the speed of extension and retraction can be adjusted to match the operational requirements, enabling precise and efficient operation.

Mounting options:

Telescopic cylinders can be customized with different mounting options to facilitate easy integration with specific machinery and equipment. Mounting configurations can vary depending on factors such as available space, mounting orientation, and compatibility with existing systems. Manufacturers can provide various mounting solutions to ensure seamless installation.

Sealing and protection:

In certain applications, telescopic cylinders may require specialized sealing and protection features. Manufacturers can customize the cylinder design to incorporate seals and protective coatings that are suitable for the working environment. This customization helps enhance the longevity and reliability of the cylinder, especially in harsh operating conditions.

Material selection:

Telescopic cylinders can be manufactured using different materials to meet specific machinery and equipment requirements. Material selection depends on factors such as load capacity, operating temperature, corrosion resistance, and weight considerations. Manufacturers can offer material options to ensure the cylinder’s compatibility and performance in the intended application.

Integration with control systems:

Telescopic cylinders can be integrated with control systems and sensors to enable advanced functionality and automation. Customization may involve incorporating position sensors, pressure sensors, or other feedback devices to provide real-time data and enhance the overall performance and safety of the machinery or equipment.

Overall, telescopic cylinders can be customized in terms of stroke length, force and speed adjustability, mounting options, sealing and protection features, material selection, and integration with control systems. This customization allows telescopic cylinders to be tailored to the specific requirements of machinery and equipment, ensuring optimal performance and functionality.

It’s important to collaborate with the manufacturer or a qualified expert to determine the appropriate customization options and ensure compliance with relevant industry standards and regulations.

editor by Dream 2024-04-26

China high quality China Famous Telescopic Hydraulic Cylinder for Dumper Truck in Mine with Good quality

Product Description

Product description:

Junfu is famous brand in front-end cylinders, offering an extensive catalogue from 5 to 100 tons with bespoke solutions. Designed for rear-end tippers and tippers trailers, CHINAMFG brand front-end telescopic cylinders are known for their durability, reliability in all conditions and value for money. We believe in delivering a solution that can rapidly and successfully meet your requirements in demanding industries such as transportation, construction and mining. With high payload and longer service intervals for increased operating time, CHINAMFG brand front-end cylinders are also environmentally friendly solutions with lower oil & fuel consumption.

FC telescopic front-end(front mounting) cylinders are primarily designed for straight headboard dump trucks with a capacity range of over 100 tons tipping weight. Our trunnion type FC cylinder is lightweight, strong, maintenance free and offers the most added stability to the tipper. The CHINAMFG brand FC tipping cylinders have earned reputation for their reliability and value for money over many years.

Designed for Dump Truck applications, FC series cylinder with 3-7 stages is capable of lifting more weight which in return allows trucks to be equipped with smaller cylinders reducing space and saving weight. This CHINAMFG series cylinder is mostly used in combination with a Straight Headboard Type and Trunnion Type Body Connection.

The hydraulic system including hydraulic oil tank, gear pump, lift valve, air control valve and limit valve, oil pipe and joints.

Product Details

| series | model |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

ΦA |

Pipe joint |

Applicable cargo box length(mm) |

Overhang length(mm) |

Lifting angle |

Lifting weight(Kg) |

Fuel tank selection |

|

1 3 7 |

3TG-F137*3830 |

200 |

65 |

360 |

60 |

325 |

1585 |

Φ60 |

G1 |

4700-5300 |

800 |

47-52° |

43 |

80 |

|

4TG-F137*3830 |

200 |

65 |

360 |

60 |

325 |

1270 |

Φ60 |

G1 |

4700-5300 |

800 |

47-52° |

31 |

80 |

|

|

4TG-F137*4280 |

200 |

65 |

360 |

60 |

325 |

1390 |

Φ60 |

G1 |

5300-6000 |

800 |

47-52° |

36 |

80 |

|

|

4TG-F137*4800 |

200 |

65 |

360 |

60 |

325 |

1510 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

36 |

80 |

|

|

1 5 7 |

4TG-F157*4280 |

245 |

65 |

360 |

60 |

325 |

1385 |

Φ60 |

G1 |

5300-5800 |

800 |

47-52° |

53 |

80 |

|

4TG-F157*4800 |

245 |

65 |

360 |

60 |

325 |

1505 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

53 |

100 |

|

|

4TG-F157*5100 |

245 |

65 |

360 |

60 |

325 |

1580 |

Φ60 |

G1 |

6200-6800 |

800 |

47-52° |

58 |

100 |

|

|

4TG-F157*5390 |

245 |

65 |

360 |

60 |

325 |

1655 |

Φ60 |

G1 |

6600-7200 |

800 |

47-52° |

58 |

100 |

|

|

5TG-F157*4050 |

245 |

65 |

360 |

60 |

325 |

1125 |

Φ60 |

G1 |

5000-5500 |

800 |

47-52° |

46 |

80 |

|

|

5TG-F157*4280 |

245 |

65 |

360 |

60 |

325 |

1165 |

Φ60 |

G1 |

5300-6000 |

800 |

47-52° |

46 |

80 |

|

|

5TG-F157*4800 |

245 |

65 |

360 |

60 |

325 |

1265 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

49 |

80 |

|

|

5TG-F157*5100 |

245 |

65 |

360 |

60 |

325 |

1340 |

Φ60 |

G1 |

6200-6800 |

800 |

47-52° |

49 |

80 |

|

|

5TG-F157*5390 |

245 |

65 |

360 |

60 |

325 |

1385 |

Φ60 |

G1 |

6600-7200 |

800 |

47-52° |

49 |

80 |

|

|

1 7 9 |

4TG-F179*4600 |

245 |

65 |

360 |

65 |

325 |

1455 |

Φ60 |

G1 |

5600-6300 |

800 |

47-52° |

66 |

120 |

|

4TG-F179*4800 |

245 |

65 |

360 |

65 |

325 |

1505 |

Φ60 |

G1 |

5800-6500 |

800 |

47-52° |

66 |

120 |

|

|

4TG-F179*5100 |

245 |

65 |

360 |

65 |

325 |

1580 |

Φ60 |

G1 |

6200-6800 |

800 |

47-52° |

70 |

120 |

|

|

4TG-F179*5390 |

245 |

65 |

360 |

65 |

325 |

1655 |

Φ60 |

G1 |

6600-7200 |

800 |

47-52° |

70 |

120 |

|

|

4TG-F179*5780 |

245 |

65 |

360 |

65 |

325 |

1750 |

Φ60 |

G1 |

7200-8000 |

1000 |

47-52° |

70 |

135 |

|

|

6TG-F179*5780 |

245 |

65 |

360 |

65 |

325 |

1270 |

Φ60 |

G1 |

7200-8000 |

1000 |

47-52° |

49 |

120 |

|

|

2 0 2 |

4TG-F202*5390 |

280 |

65 |

360 |

65 |

325 |

1675 |

Φ65 |

G1 |

6600-7200 |

800 |

47-52° |

92 |

165 |

|

4TG-F202*5780 |

280 |

65 |

360 |

65 |

325 |

1770 |

Φ65 |

G1 |

7200-8000 |

1000 |

47-52° |

96 |

165 |

|

|

4TG-F202*6180 |

280 |

65 |

360 |

65 |

325 |

1870 |

Φ65 |

G1 |

8000-8500 |

1000 |

47-52° |

96 |

185 |

|

|

5TG-F202*7200 |

280 |

65 |

360 |

65 |

325 |

1770 |

Φ65 |

G1 |

8700-9500 |

1000 |

47-52° |

88 |

185 |

Note: The above product models are our company’s regular product models. Customers are requested to choose regular products as much as possible, which can improve the delivery time and service quality.

Workshop with advanced equipment:

Exhibition:

Certificates: ISO9001, IATF 16949:2016, CE,etc.

FAQ:

Q1: How about your cylinders compared with HYVA cylinder ?

Our cylinders can replace HYVA cylinder well, with same technical details and mounting sizes

Q2: What’s your cylinder’s advantages ?

The cylinders are manufactured by advanced equipments and made under strictly quality control processing.

The steel is quenched and tempered 27SiMn steel and all raw materials are good quality from world famous companies.

Competitive price!

Q3: When your company be established ?

Our company be established in 2002, professional manufacturer of hydraulic cylinders more than 20 years.

We had passed IATF 16949:2016 Quality control system, ISO9001, CE,etc.

Q4: How about the delivery time ?

7-15 days approximately.

Q5: How about the cylinder’s quality gurantee ?

One year.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

What advantages do telescopic cylinders offer in heavy equipment?

Telescopic cylinders offer several advantages in heavy equipment applications. Here’s a detailed explanation:

Compact design:

Telescopic cylinders have a compact design that allows for a relatively small retracted length compared to their extended length. This compactness is advantageous in heavy equipment where space is limited. The reduced length enables the equipment to have a smaller footprint, making it easier to maneuver in confined areas and transport on trailers or trucks.

Extended reach:

Telescopic cylinders provide extended reach capabilities, which is beneficial in heavy equipment operations. The nested design allows for multiple stages to extend, enabling the cylinder to reach greater distances. This extended reach is particularly useful in applications where the equipment needs to lift or push loads over obstacles, reach into deep pits, or access elevated areas.

High force output:

Telescopic cylinders are capable of generating high force output, making them suitable for heavy lifting and pushing tasks. The hydraulic system used in telescopic cylinders allows for amplification of force through the application of hydraulic pressure. This high force output is advantageous in heavy equipment applications that require lifting and moving heavy loads or exerting significant pushing or pulling forces.

Customizable load capacity:

Telescopic cylinders offer load capacity customization. The modular nature of telescopic cylinders allows for the addition or removal of stages, which directly affects the cylinder’s load capacity. By adjusting the number of stages, the cylinder’s load capacity can be tailored to the specific requirements of the heavy equipment, ensuring optimal performance and safety.

Smooth operation:

Telescopic cylinders provide smooth and controlled operation. The hydraulic control system allows for precise control of the cylinder’s extension and retraction, ensuring smooth and synchronized movement of multiple stages. This smooth operation is important in heavy equipment applications where precise positioning, lifting, or pushing is required to avoid damage to the equipment or the load.

Durability and reliability:

Telescopic cylinders are built to withstand heavy-duty usage in demanding environments. They are designed using robust materials and undergo rigorous testing to ensure durability and reliability. The cylinders can withstand high load capacities, harsh operating conditions, and repetitive cycles, making them well-suited for heavy equipment applications that involve continuous and demanding operations.

Overall, telescopic cylinders offer advantages such as compact design, extended reach, high force output, customizable load capacity, smooth operation, durability, and reliability. These advantages contribute to improved efficiency, productivity, and performance of heavy equipment in various industries.

It’s important to consult the manufacturer’s specifications and guidelines to ensure the appropriate selection and application of telescopic cylinders in heavy equipment.

Can telescopic cylinders be used in aerial work platforms for extended reach?

Yes, telescopic cylinders are commonly used in aerial work platforms to achieve extended reach. Here’s a detailed explanation:

Increased working height:

Telescopic cylinders enable aerial work platforms to reach greater heights compared to other types of lifting mechanisms. The multi-stage design of telescopic cylinders allows for sequential extension, providing incremental increases in working height. This extended reach capability is crucial for accessing elevated areas such as construction sites, maintenance tasks, or elevated platforms.

Flexible reach adjustment:

Telescopic cylinders offer flexibility in adjusting the reach of aerial work platforms. By extending or retracting the cylinders, operators can modify the platform’s horizontal reach according to the specific job requirements. This flexibility allows for precise positioning of the platform, ensuring safe and efficient access to work areas at varying distances from the base.

Stability and load capacity:

Telescopic cylinders contribute to the stability and load capacity of aerial work platforms during extended reach operations. The cylinders provide structural support and help distribute the weight of the platform and the load being lifted. This load distribution ensures stability, minimizes the risk of tipping or tilting, and allows for safe operation even at maximum reach.

Controlled movements:

Telescopic cylinders enable controlled and smooth movements of aerial work platforms. The hydraulic control system regulates the extension and retraction of the cylinders, allowing for precise control over the platform’s vertical and horizontal motions. This controlled movement enhances operator safety, minimizes vibrations, and enables accurate positioning of the platform during extended reach tasks.

Compact design:

Telescopic cylinders offer a compact design that allows for efficient integration into aerial work platforms. The cylinders can be retracted when not in use, minimizing the space occupied by the lifting mechanism. This compactness allows for better maneuverability, improved accessibility in confined spaces, and efficient transportation of the aerial work platform.

Integration with other platform features:

Telescopic cylinders can be integrated with other features of aerial work platforms to enhance functionality. For example, they can be combined with articulating booms or rotating platforms to achieve versatile reach and positioning capabilities. This integration expands the range of applications for aerial work platforms, enabling them to navigate obstacles, reach over obstacles, or access difficult-to-reach areas.

Advantages of telescopic cylinders in aerial work platforms:

Telescopic cylinders offer several advantages when used in aerial work platforms for extended reach:

- Increased working height for accessing elevated areas

- Flexible reach adjustment for precise positioning

- Stability and load capacity during extended reach

- Controlled movements for operator safety

- Compact design for maneuverability and transportation

- Integration with other platform features for enhanced functionality

Overall, telescopic cylinders are a reliable and efficient choice for achieving extended reach in aerial work platforms. Their ability to increase working height, provide flexibility in reach adjustment, ensure stability, enable controlled movements, offer a compact design, and integrate with other platform features makes them well-suited for a wide range of aerial work applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in aerial work platforms.

What are the benefits of using telescopic cylinders for long-reach tasks?

Telescopic cylinders offer several benefits when it comes to long-reach tasks. Here’s a detailed explanation:

Extended reach:

One of the primary advantages of telescopic cylinders is their ability to provide extended reach. By utilizing a nested structure with multiple stages, telescopic cylinders can achieve significantly longer stroke lengths compared to other types of cylinders. This extended reach is beneficial for tasks that require accessing or manipulating objects or materials at a distance.

Compact retracted length:

Despite their extended reach, telescopic cylinders have a relatively compact retracted length. This is advantageous in situations where space is limited or when a shorter cylinder length is preferred. The compact retracted length enables telescopic cylinders to be installed in confined areas or integrated into equipment without excessive protrusion.

Flexible and adjustable:

Telescopic cylinders offer flexibility and adjustability, allowing for fine-tuning of the stroke length, force, and speed. This adjustability is particularly useful in long-reach tasks where precise control and positioning are required. The hydraulic control system of telescopic cylinders enables operators to optimize the cylinder’s performance according to the specific task and operating conditions.

High force capabilities:

Telescopic cylinders are designed to handle heavy loads and can generate substantial force. This makes them suitable for long-reach tasks that involve lifting, pushing, pulling, or manipulating objects at a distance. The high force capabilities of telescopic cylinders ensure that the required power is available to perform the task effectively.

Enhanced stability:

Telescopic cylinders are engineered to provide stability during long-reach tasks. The nested structure and hydraulic control system work together to ensure synchronized and controlled extension and retraction of the stages. This stability is crucial for maintaining precise positioning, minimizing oscillations or vibrations, and preventing potential hazards or accidents.

Versatility:

Telescopic cylinders find applications in various industries and tasks that involve long-reach requirements. They are commonly used in construction equipment, material handling machinery, cranes, booms, and many other applications where extended reach is necessary.

Overall, the benefits of using telescopic cylinders for long-reach tasks include extended reach, compact retracted length, flexibility, high force capabilities, enhanced stability, and versatility. These advantages make telescopic cylinders a valuable choice for tasks that require reaching or manipulating objects at a distance.

It’s important to consult the manufacturer’s guidelines and specifications to ensure the proper selection, installation, and operation of telescopic cylinders based on the specific long-reach task requirements.

editor by Dream 2024-04-26

China Best Sales CZPT Jinqi Mindman Hydraulic Clamping Cylinder Mhck-25/32/40/50/63-F Hydraulic Lever Cylinder vacuum pump booster

Product Description

Q1: How can contact sales?

A1: Contact with us in TraderManager, or send email to us.

Q2: How to make payment?

A2: Paypal, Western Union, Money Gram or T/T transfer

Q3: How long does it take to process orders?

A3:It usually takes 10-14 business days to process most orders for no stock, if stock available, only take 2- 3 business days.

Q4: What is the packing method?

A4: For small piece, we use carton box; for big piece, we use exporting grade plywood case.

Q5: How to ship?

A5: Sea freight, Air freight or International express(DHL, FEDEX,UPS…) all are available.

Q6: What is the warranty

A6: 12 months against B/L date

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do hydraulic cylinders handle the challenges of precise positioning and control?

Hydraulic cylinders are designed to handle the challenges of precise positioning and control with a combination of engineering principles and advanced control systems. These challenges often arise in applications where accurate and controlled movements are required, such as in industrial automation, construction, and material handling. Here’s a detailed explanation of how hydraulic cylinders overcome these challenges:

1. Fluid Power Control:

– Hydraulic cylinders utilize fluid power control to achieve precise positioning and control. The hydraulic system consists of a hydraulic pump, control valves, and hydraulic fluid. By regulating the flow of hydraulic fluid into and out of the cylinder, operators can control the speed, direction, and force exerted by the cylinder. The fluid power control allows for smooth and accurate movements, enabling precise positioning of the hydraulic cylinder and the attached load.

2. Control Valves:

– Control valves play a crucial role in handling the challenges of precise positioning and control. These valves are responsible for directing the flow of hydraulic fluid within the system. They can be manually operated or electronically controlled. Control valves allow operators to adjust the flow rate of the hydraulic fluid, controlling the speed of the cylinder’s movement. By modulating the flow, operators can achieve fine control over the positioning of the hydraulic cylinder, enabling precise and accurate movements.

3. Proportional Control:

– Hydraulic cylinders can be equipped with proportional control systems, which offer enhanced precision in positioning and control. Proportional control systems utilize electronic feedback and control algorithms to precisely regulate the flow and pressure of the hydraulic fluid. These systems provide accurate and proportional control over the movement of the hydraulic cylinder, allowing for precise positioning at various points along its stroke length. Proportional control enhances the cylinder’s ability to handle complex tasks that require precise movements and control.

4. Position Feedback Sensors:

– To achieve precise positioning, hydraulic cylinders often incorporate position feedback sensors. These sensors provide real-time information about the position of the cylinder’s piston rod. Common types of position feedback sensors include potentiometers, linear variable differential transformers (LVDTs), and magnetostrictive sensors. By continuously monitoring the position, the feedback sensors enable closed-loop control, allowing for accurate positioning and control of the hydraulic cylinder. The feedback information is used to adjust the flow of hydraulic fluid to achieve the desired position accurately.

5. Servo Control Systems:

– Advanced hydraulic systems employ servo control systems to handle the challenges of precise positioning and control. Servo control systems combine electronic control, position feedback sensors, and proportional control valves to achieve high levels of accuracy and responsiveness. The servo control system continuously compares the desired position with the actual position of the hydraulic cylinder and adjusts the flow of hydraulic fluid to minimize any positional error. This closed-loop control mechanism enables the hydraulic cylinder to maintain precise positioning and control, even under varying loads or external disturbances.

6. Integrated Automation:

– Hydraulic cylinders can be integrated into automated systems to achieve precise positioning and control. In such setups, the hydraulic cylinders are controlled by programmable logic controllers (PLCs) or other automation controllers. These controllers receive input signals from various sensors and use pre-programmed logic to command the hydraulic cylinder’s movements. The integration of hydraulic cylinders into automated systems allows for precise and repeatable positioning and control, enabling complex sequences of movements to be executed with high accuracy.

7. Advanced Control Algorithms:

– Advancements in control algorithms have also contributed to the precise positioning and control of hydraulic cylinders. These algorithms, such as PID (Proportional-Integral-Derivative) control, adaptive control, and model-based control, enable sophisticated control strategies to be implemented. These algorithms consider factors such as load variations, system dynamics, and environmental conditions to optimize the control of hydraulic cylinders. By employing advanced control algorithms, hydraulic cylinders can compensate for disturbances and achieve precise positioning and control over a wide range of operating conditions.

In summary, hydraulic cylinders overcome the challenges of precise positioning and control through the use of fluid power control, control valves, proportional control, position feedback sensors, servo control systems, integrated automation, and advanced control algorithms. By combining these elements, hydraulic cylinders can achieve accurate and controlled movements, enabling precise positioning and control in various applications. These capabilities are essential for industries that require high precision and repeatability in their operations, such as industrial automation, robotics, and material handling.

Ensuring Controlled and Safe Force Application in Heavy Machinery with Hydraulic Cylinders

Hydraulic cylinders play a critical role in heavy machinery by ensuring controlled and safe force application. The ability to exert and control high forces is essential for heavy machinery operations, such as lifting, pressing, pushing, or pulling heavy loads. Let’s explore how hydraulic cylinders ensure controlled and safe force application in heavy machinery:

- Force Control: Hydraulic cylinders provide precise force control capabilities. The hydraulic system’s pressure can be adjusted to regulate the force exerted by the cylinder. This control allows operators to apply the necessary force for a specific task while ensuring it remains within safe limits. By accurately controlling the force, hydraulic cylinders help prevent excessive force that could damage the machinery or compromise the safety of the operation.

- Load Balancing: In heavy machinery, multiple hydraulic cylinders are often used in conjunction to distribute and balance the applied force. By using multiple cylinders, the load can be evenly distributed across the machinery, minimizing stress concentrations and ensuring controlled force application. This load balancing approach enhances the stability and safety of the machinery, preventing uneven loading that could lead to structural issues or instability.

- Safety Valves: Hydraulic systems in heavy machinery are equipped with safety valves to protect against excessive force or overloading. Safety valves are designed to release hydraulic fluid from the cylinder when the force exceeds a predetermined threshold. This prevents the force from reaching dangerous levels, safeguarding the machinery and preventing potential accidents or damage. Safety valves provide an additional layer of safety and ensure controlled force application even in unexpected circumstances.

- Pressure Relief Systems: Hydraulic cylinders incorporate pressure relief systems to further enhance safety. These systems are designed to relieve excess pressure in the hydraulic system, which could occur due to factors such as thermal expansion or system malfunctions. By relieving excess pressure, the pressure relief systems prevent sudden and uncontrolled force surges, maintaining safe and controlled force application in heavy machinery.

- Structural Integrity: Hydraulic cylinders are designed to withstand the high forces and loads associated with heavy machinery applications. The cylinders are constructed using robust materials, such as high-strength steel, and undergo rigorous testing to ensure their structural integrity. This ensures that the cylinders can safely handle the forces applied during heavy machinery operations without experiencing failures or deformations that could compromise the safety and controlled force application.

In summary, hydraulic cylinders ensure controlled and safe force application in heavy machinery through force control, load balancing, safety valves, pressure relief systems, and robust structural design. These features and design considerations enable operators to exert the necessary force while maintaining safety and preventing excessive loads or force surges. By incorporating hydraulic cylinders into heavy machinery, manufacturers can achieve controlled force application, enhance operational safety, and protect the machinery from damage or failure.

Can you explain the role and significance of hydraulic cylinders in machinery?

Hydraulic cylinders play a crucial role in machinery across various industries. They are essential components that provide controlled and powerful linear motion, enabling the operation of heavy equipment and facilitating numerous tasks. The role and significance of hydraulic cylinders in machinery can be explained in detail as follows:

Role of Hydraulic Cylinders:

– Conversion of Hydraulic Energy: Hydraulic cylinders convert hydraulic energy, typically in the form of pressurized hydraulic fluid, into linear force and motion. This conversion allows machinery to perform tasks such as lifting, pushing, pulling, clamping, tilting, and controlling various mechanisms.

– Generation of Linear Motion: Hydraulic cylinders generate linear motion by utilizing the principles of Pascal’s law. When hydraulic fluid is directed into one side of the cylinder, it applies pressure on the piston, resulting in linear movement of the piston and the attached piston rod. This linear motion can be used to actuate other components within the machinery or directly perform the required task.

– Force Generation: Hydraulic cylinders are capable of generating high forces due to the hydraulic pressure applied to the piston. The force output of a hydraulic cylinder depends on the surface area of the piston and the pressure of the hydraulic fluid. This force allows machinery to exert significant power for lifting heavy loads, applying pressure, or overcoming resistance.

– Precise Control: Hydraulic cylinders offer precise control over the linear motion and force exerted. By regulating the flow of hydraulic fluid, the speed and direction of the cylinder’s movement can be accurately adjusted. This level of control is crucial in machinery that requires precise positioning, delicate movements, or synchronization of multiple cylinders.

– Integration with Hydraulic Systems: Hydraulic cylinders are integral parts of hydraulic systems used in machinery. They work in conjunction with hydraulic pumps, valves, and actuators to create a complete hydraulic circuit. This integration allows for efficient power transmission, control, and coordination of various machine functions.

Significance of Hydraulic Cylinders:

– Heavy Equipment Operation: Hydraulic cylinders are vital in heavy machinery used in construction, mining, agriculture, material handling, and other industries. They enable the lifting and movement of heavy loads, the operation of attachments, and the performance of tasks that require high force and precision.

– Versatility and Adaptability: Hydraulic cylinders are versatile components that can be designed and tailored to meet specific machinery requirements. They can be integrated into various types of equipment and customized based on factors such as force capacity, stroke length, speed, and mounting options. This adaptability makes hydraulic cylinders suitable for diverse applications.

– Durability and Reliability: Hydraulic cylinders are built to withstand rigorous operating conditions, including high pressures, heavy loads, and continuous use. They are designed with robust materials, precise machining, and effective sealing systems to ensure durability and reliability over extended periods of operation.

– Safety and Load Control: Hydraulic cylinders provide safe and controlled operation in machinery. They offer overload protection mechanisms, such as relief valves, to prevent damage caused by excessive force or pressure. Additionally, hydraulic cylinders allow for precise load control, minimizing the risk of accidents during lifting, lowering, or positioning of heavy loads.

– Compact Design: Hydraulic cylinders offer a high power-to-size ratio, allowing for compact machinery design. Their relatively small size compared to the forces they can generate makes them suitable for applications where space is limited or weight restrictions apply.

– Energy Efficiency: Hydraulic cylinders contribute to energy efficiency in machinery. The use of hydraulic systems allows for the transfer of power over long distances without significant power losses. Additionally, hydraulic cylinders can incorporate energy-saving features such as load-sensing technology and regenerative circuits, reducing energy consumption.

Overall, hydraulic cylinders play a vital role in machinery by providing controlled and powerful linear motion. Their significance lies in their ability to convert hydraulic energy, generate high forces, offer precise control, integrate with hydraulic systems, and facilitate the operation of heavy equipment across various industries. Hydraulic cylinders contribute to increased productivity, safety, and efficiency in machinery applications, making them indispensable components in modern-day engineering.

editor by Dream 2024-04-25

China Best Sales Multi Stages Telescopic Multistage Hydraulic Cylinder for Trailer Dump Truck Body Telescopic Cylinder vacuum pump design

Product Description

Specifications:

| Product Name | SGS Series Hydraulic Cylinder |

| Work Press | 7/14/16/21/31.5MPa |

| Material | Aluminum, Cast Iron,45mnb Steel, Stainless Steel |

| Stage | Up to 5 Stage |

| Bore Size | 40mm–320mm, Customizable |

| Shaft Diameter | 20mm–220mm, Customizable |

| Stroke Length | 30mm–14100mm, Customizable |

| Rod Surface Hardness | HRC48-54 |

| Operating Temperature | -40°C to +120 °C |

| Paint Color | Black, Yellow, Blue, Brown, Customizable |

| Service | OEM&ODM |

| Warranty | 1 Year |

| MOQ | 1 Piece |

| Delivery Time | 7-15 Days, Also depending on specific demands |

| Certification | ISO9001,CE |

| Capacity | 50,000Pcs per year |

Product Display:

Mounting:

Working Flow: About Us

Tongte designs and manufactures durable, heavy-duty hydraulic products and accessories and offers lifecycle services to them. We constantly develop our machine base and operations to meet customer-specific needs and remain leaders in the industry. Beyond all else, we want to be the trusted, groundbreaking partner our customers truly need.

In addition to the customized cylinders, CHINAMFG offers hydraulic power units, Electric-Hydraulic linear actuators, piston accumulators, system configurations, and versatile services such as repair and manufacturing services. The modern production facilities are located in HangZhou, ZheJiang (China) where production started in 2001. The core values of Tongke guiding its business strongly are commitment, sustainability, interaction, and customer-first.

We possess over 20 years of experience in the industry and extensive global market experience, our customers are located all over the world, and we truly commit to the customers’ needs – these are the success factors of our family-owned company. Our vision is to grow and expand the business further into global markets.

FAQ:

Q1: What does your company do?

A: we are a supplier of high-quality hydraulic products including Hydraulic Cylinders, Hydraulic Power packs, Hydraulic Linear, and other Hydraulic components.

Q2:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q3:Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, and 15-30 working days if we don’t. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What is your warranty policy?

A: All our products are warranted for 1 full year from the date of delivery against defects in materials and workmanship. Each individual product will be strictly inspected on our factory QC Process

System before shipment. We also have a Customer Service team to respond to customers’ questions within 12 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do telescopic cylinders handle variations in environmental conditions?

Telescopic cylinders are designed to handle variations in environmental conditions effectively. Here’s a detailed explanation:

Durable construction:

Telescopic cylinders are constructed with durable materials such as steel or high-strength alloys, which provide resistance to environmental elements. These materials are chosen for their ability to withstand harsh conditions, including temperature extremes, moisture, and exposure to chemicals or corrosive substances.

Sealing mechanisms:

Telescopic cylinders incorporate sealing mechanisms to protect the internal components from contaminants and maintain proper operation in different environments. The seals prevent the entry of dust, dirt, water, and other particles that could potentially damage the cylinder’s internal components or affect its performance. Seals also help retain the hydraulic fluid, ensuring optimal lubrication and preventing leakage.

Corrosion resistance:

Telescopic cylinders are often coated with protective finishes or treatments to enhance their corrosion resistance. These coatings, such as paint, powder coating, or specialized coatings like chrome plating, create a barrier between the cylinder’s surface and the surrounding environment, reducing the risk of corrosion. Corrosion-resistant materials and treatments are particularly crucial in outdoor or marine applications where exposure to moisture, saltwater, or chemicals is common.

Temperature considerations:

Telescopic cylinders are designed to handle variations in temperature. The materials used in their construction are selected to withstand both low and high temperature ranges. Additionally, the hydraulic fluid used in the cylinders is chosen based on its ability to maintain consistent performance across different temperature conditions. In extreme temperature environments, additional insulation or heating elements may be incorporated to ensure proper fluid viscosity and prevent freezing or overheating.

Environmental sealing:

In certain applications where telescopic cylinders are exposed to extreme environmental conditions, additional sealing measures may be implemented. Environmental seals are designed to provide extra protection against water, dust, or other contaminants that are prevalent in specific environments. These seals are typically more robust and durable to maintain the integrity of the cylinder in challenging conditions.

Regular maintenance:

To ensure optimal performance and longevity, regular maintenance is essential for telescopic cylinders. This includes inspecting and cleaning the cylinders, checking and replacing worn seals, monitoring fluid levels and quality, and addressing any signs of damage or wear. Maintenance intervals may vary depending on the operating conditions and manufacturer recommendations.

Overall, telescopic cylinders are engineered to handle variations in environmental conditions by incorporating durable construction, sealing mechanisms, corrosion resistance, temperature considerations, environmental sealing, and regular maintenance. These features contribute to the reliability, longevity, and performance of telescopic cylinders in diverse industrial applications.

Consulting with manufacturers or industry experts can provide further guidance on selecting telescopic cylinders that are suitable for specific environmental conditions.

Can telescopic cylinders be used in aerial work platforms for extended reach?

Yes, telescopic cylinders are commonly used in aerial work platforms to achieve extended reach. Here’s a detailed explanation:

Increased working height:

Telescopic cylinders enable aerial work platforms to reach greater heights compared to other types of lifting mechanisms. The multi-stage design of telescopic cylinders allows for sequential extension, providing incremental increases in working height. This extended reach capability is crucial for accessing elevated areas such as construction sites, maintenance tasks, or elevated platforms.

Flexible reach adjustment:

Telescopic cylinders offer flexibility in adjusting the reach of aerial work platforms. By extending or retracting the cylinders, operators can modify the platform’s horizontal reach according to the specific job requirements. This flexibility allows for precise positioning of the platform, ensuring safe and efficient access to work areas at varying distances from the base.

Stability and load capacity:

Telescopic cylinders contribute to the stability and load capacity of aerial work platforms during extended reach operations. The cylinders provide structural support and help distribute the weight of the platform and the load being lifted. This load distribution ensures stability, minimizes the risk of tipping or tilting, and allows for safe operation even at maximum reach.

Controlled movements:

Telescopic cylinders enable controlled and smooth movements of aerial work platforms. The hydraulic control system regulates the extension and retraction of the cylinders, allowing for precise control over the platform’s vertical and horizontal motions. This controlled movement enhances operator safety, minimizes vibrations, and enables accurate positioning of the platform during extended reach tasks.

Compact design:

Telescopic cylinders offer a compact design that allows for efficient integration into aerial work platforms. The cylinders can be retracted when not in use, minimizing the space occupied by the lifting mechanism. This compactness allows for better maneuverability, improved accessibility in confined spaces, and efficient transportation of the aerial work platform.

Integration with other platform features:

Telescopic cylinders can be integrated with other features of aerial work platforms to enhance functionality. For example, they can be combined with articulating booms or rotating platforms to achieve versatile reach and positioning capabilities. This integration expands the range of applications for aerial work platforms, enabling them to navigate obstacles, reach over obstacles, or access difficult-to-reach areas.

Advantages of telescopic cylinders in aerial work platforms:

Telescopic cylinders offer several advantages when used in aerial work platforms for extended reach:

- Increased working height for accessing elevated areas

- Flexible reach adjustment for precise positioning

- Stability and load capacity during extended reach

- Controlled movements for operator safety

- Compact design for maneuverability and transportation

- Integration with other platform features for enhanced functionality

Overall, telescopic cylinders are a reliable and efficient choice for achieving extended reach in aerial work platforms. Their ability to increase working height, provide flexibility in reach adjustment, ensure stability, enable controlled movements, offer a compact design, and integrate with other platform features makes them well-suited for a wide range of aerial work applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the integration, operation, and maintenance of telescopic cylinders in aerial work platforms.

How does a telescopic cylinder handle variations in extension and retraction?

A telescopic cylinder is designed to handle variations in extension and retraction through its inherent structure and hydraulic system. Here’s a detailed explanation:

Handling variations in extension:

When extending a telescopic cylinder, each stage or sleeve extends successively, one inside the other, to achieve the desired stroke length. This nested structure allows for incremental extension, providing flexibility in adapting to different extension requirements. The hydraulic system supplies pressurized fluid to each stage’s piston, generating the necessary force for extension. The internal flow paths in the cylinder ensure synchronized movement of the stages, allowing for controlled and precise extension.

Handling variations in retraction:

During retraction, the telescopic cylinder stages retract in the reverse order of extension. The hydraulic system controls the flow of fluid to each stage, allowing for controlled retraction. The nested structure of the cylinder ensures that each stage retracts smoothly inside the preceding stage. The hydraulic pressure and flow are regulated to prevent rapid or uncontrolled retraction, ensuring safe and stable operation.

Compensating for variations:

Telescopic cylinders are designed to compensate for variations in extension and retraction through their hydraulic control systems. The hydraulic system can be adjusted to vary the flow rate, pressure, or force applied to each stage, allowing for fine-tuning and accommodating different extension and retraction requirements. Additionally, the locking mechanisms incorporated in telescopic cylinders help maintain the extended position securely, compensating for external forces or variations in loads.

Overall, the nested structure, hydraulic system, and locking mechanisms of telescopic cylinders provide the necessary flexibility and control to handle variations in extension and retraction. This enables the cylinders to adapt to different operating conditions, loads, and stroke length requirements in various applications.

It’s important to follow the manufacturer’s guidelines and recommendations for proper operation, maintenance, and adjustment of telescopic cylinders to ensure their reliable and safe performance.

editor by Dream 2024-04-25

China manufacturer Factory Direct High Quality Telescopic Hydraulic Cylinder vacuum pump belt

Product Description

Product Description

Renewable energy hydraulic cylinder:

HETLOCK comply with development and demand of the times. We are further study in the field of renewable energy. Has been successfully to entered many customer in the field of wind power.

And reference to bridge jack-up experience of rise and fall. Creatively to installed the hydraulic valve into the hydraulic cylinder directly. Improve the stability when hydraulic cylinder ruining. And to avoid the hydraulic cylinder suddenly fall off due to tube crack.

Our products have applications in:

- Wind energy;

- Nuclear energy;

- Solar Thermal energy;

- Marine energy

- Etc.

Product Parameters

| Material | Carbon steel, Alloy steel, Stainless steel |

| Honed tube | 20-2500mm, Heat treatment, honing, rolling |

| Piston rod | 10-2000mm ,tempering, plated nickel, Chromium or ceramic |

| Working Pressure | 5-300Mpa |

| Seals | Parker,Merkel,Hallite |

| Technology | Bosch CHINAMFG and Parker |

| Coating | Sandblasting, primer, middle paint, finish paint |

| Temperature range | -40ºC to +300ºC |

| Work medium | Hydraulic Oil |

| Piston speed | maximum 2m/s |

| Mounting style | Earrings, flange, foot mounting, screw thread. |

Product Application

Company Show

HETLOCK is a professional manufacturer of hydraulic cylinders in China, Founded in 1998, located in the international city of ZheJiang . Our plant is nearly 20000 square meter& We have 135 Employees including 11 experienced engineers and technical staff,More than 1800 type of hydraulic cylinder designed in every year. We can produce various kinds of hydraulic cylinders according to customer requirements.

The inside diameter of hydraulic cylinders can achieve the maximum 2500mm;

The hydraulic cylinders operating pressure can achieve the maximum 300MPa.

FAQ

Q1:Are you a manufacturer or trading company?

A: We are a manufacturer.

Q2: How many years of production experience do you have?

A: We have over 20 years of production experience.

Q3: Can it be customized?

A: Both standard and non-standard products can be customized.

Q4: How to ensure product quality?

A: We strictly follow the quality process for production and 100% inspection of each batch of products.

Q5: What services can you provide?

A: According to customer requirements, we can provide a one-stop solution from design, production, and delivery to meet their needs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

What safety considerations are important when using machinery with telescopic cylinders?

When using machinery with telescopic cylinders, several safety considerations should be taken into account. Here’s a detailed explanation:

Operator training and awareness:

Proper training and awareness are crucial for operators working with machinery equipped with telescopic cylinders. Operators should receive comprehensive training on the safe operation of the machinery, including the correct use of telescopic cylinders. They should be familiar with the controls, safety features, and best practices to ensure their own safety and the safety of others in the vicinity.

Regular inspection and maintenance:

Regular inspection and maintenance of telescopic cylinders are essential for ensuring safe operation. Cylinders should be inspected for signs of wear, damage, or leakage. Any issues should be addressed promptly to prevent potential failures or accidents. Lubrication, if required, should be performed according to the manufacturer’s recommendations.

Proper load capacity and stability:

It is important to ensure that the machinery and telescopic cylinders are used within their specified load capacity. Exceeding the load capacity can lead to instability, loss of control, or structural failure. Proper weight distribution and secure attachment of loads are also critical to maintaining stability during operation.

Safe work environment:

Creating a safe work environment is essential when using machinery with telescopic cylinders. This includes maintaining clear and unobstructed pathways for the machinery’s movement, removing potential hazards, and implementing appropriate safety measures such as barriers, signage, or warning systems to prevent unauthorized access or accidental contact with the machinery or its cylinders.

Emergency stop and shutdown procedures:

Emergency stop and shutdown procedures should be clearly communicated to operators. They should be trained on how to quickly and effectively stop the machinery’s operation in case of an emergency or when a safety hazard is detected. These procedures should be regularly reviewed and practiced to ensure a prompt response in critical situations.

Proper guarding and protection:

Telescopic cylinders should be adequately guarded to prevent accidental contact and potential injuries. Guarding may include physical barriers, shields, or sensors that detect the presence of personnel or objects in the cylinder’s path. Additionally, operators should wear appropriate personal protective equipment (PPE) as recommended for the specific task and working environment.

Compliance with regulations and standards:

It is important to ensure compliance with relevant regulations and safety standards when using machinery with telescopic cylinders. These regulations and standards may address aspects such as design, installation, operation, maintenance, and inspection of the machinery and its components. Adhering to these requirements helps mitigate risks and promotes a safe working environment.

Regular risk assessments:

Regular risk assessments should be conducted to identify and address potential hazards associated with the machinery and telescopic cylinders. This includes assessing risks related to operation, maintenance, equipment failure, environmental conditions, and human factors. Mitigation measures should be implemented based on the findings of the risk assessment.

Overall, safety considerations when using machinery with telescopic cylinders involve operator training, regular inspection and maintenance, load capacity and stability, safe work environment, emergency procedures, guarding and protection, compliance with regulations, and regular risk assessments. By addressing these considerations, the risks associated with operating machinery with telescopic cylinders can be minimized, promoting a safer working environment.

It’s important to consult the machinery manufacturer’s guidelines, safety manuals, and applicable regulations to ensure comprehensive understanding and implementation of safety practices.

How do telescopic cylinders contribute to precise reach and manipulation?

Telescopic cylinders play a crucial role in enabling precise reach and manipulation in various applications. Here’s a detailed explanation:

Extended reach:

Telescopic cylinders allow for extended reach in equipment such as cranes, excavators, booms, and material handling machinery. The nested design of telescopic cylinders, with multiple stages that retract inside one another, enables the equipment to achieve a longer reach when required. By extending the telescopic cylinder, operators can access objects or work areas that are located at a distance.

Precise positioning:

Telescopic cylinders provide precise positioning capabilities, allowing operators to manipulate objects with accuracy. The hydraulic control system regulates the extension and retraction of each stage of the cylinder, enabling smooth and controlled movement. This precise control is essential in applications that require accurate placement or manipulation of objects, such as in construction, manufacturing, or material handling.

Load handling:

Telescopic cylinders contribute to precise load handling by providing the necessary force and control. The cylinders are designed to handle heavy loads and can exert the required power to lift, lower, or manipulate objects with precision. The hydraulic control system allows operators to adjust the speed and movement of the telescopic cylinder, ensuring safe and controlled load handling.

Adaptability:

Telescopic cylinders offer adaptability in reaching and manipulating objects in various environments. Their nested design allows for compact retraction, making them suitable for applications with limited space. The ability to extend and retract the telescopic cylinder provides flexibility in adjusting the reach and adapting to different working conditions.

Support for attachments:

Telescopic cylinders often support attachments or tools that enhance reach and manipulation capabilities. For example, in excavators, telescopic cylinders are used to extend the boom or arm, while additional attachments such as buckets or grabs facilitate precise material handling or excavation tasks.

Overall, telescopic cylinders contribute to precise reach and manipulation by offering extended reach, precise positioning, load handling capabilities, adaptability, and support for attachments. Their hydraulic control system and nested design enable operators to achieve accurate and controlled movements, enhancing productivity and efficiency in various applications.

It’s important to consult the equipment manufacturer’s documentation and guidelines for specific information on the telescopic cylinder’s capabilities, operating parameters, and recommended maintenance practices to ensure optimal performance and safety.

Can telescopic cylinders be customized for specific machinery and equipment?

Yes, telescopic cylinders can be customized to meet the specific requirements of different machinery and equipment. Here’s a detailed explanation:

Customizable stroke length:

Telescopic cylinders can be designed and manufactured with customized stroke lengths to suit the specific needs of machinery and equipment. The stroke length determines the maximum extension or retraction distance of the cylinder and can be tailored to match the required range of motion for a particular application.

Adjustable force and speed:

The hydraulic control system of telescopic cylinders allows for adjustability in terms of force and speed. The system can be configured to provide the necessary force output for the machinery or equipment, ensuring optimal performance. Additionally, the speed of extension and retraction can be adjusted to match the operational requirements, enabling precise and efficient operation.

Mounting options:

Telescopic cylinders can be customized with different mounting options to facilitate easy integration with specific machinery and equipment. Mounting configurations can vary depending on factors such as available space, mounting orientation, and compatibility with existing systems. Manufacturers can provide various mounting solutions to ensure seamless installation.

Sealing and protection:

In certain applications, telescopic cylinders may require specialized sealing and protection features. Manufacturers can customize the cylinder design to incorporate seals and protective coatings that are suitable for the working environment. This customization helps enhance the longevity and reliability of the cylinder, especially in harsh operating conditions.

Material selection:

Telescopic cylinders can be manufactured using different materials to meet specific machinery and equipment requirements. Material selection depends on factors such as load capacity, operating temperature, corrosion resistance, and weight considerations. Manufacturers can offer material options to ensure the cylinder’s compatibility and performance in the intended application.

Integration with control systems:

Telescopic cylinders can be integrated with control systems and sensors to enable advanced functionality and automation. Customization may involve incorporating position sensors, pressure sensors, or other feedback devices to provide real-time data and enhance the overall performance and safety of the machinery or equipment.

Overall, telescopic cylinders can be customized in terms of stroke length, force and speed adjustability, mounting options, sealing and protection features, material selection, and integration with control systems. This customization allows telescopic cylinders to be tailored to the specific requirements of machinery and equipment, ensuring optimal performance and functionality.

It’s important to collaborate with the manufacturer or a qualified expert to determine the appropriate customization options and ensure compliance with relevant industry standards and regulations.

editor by Dream 2024-04-25

China Good quality 50t Single Acting Cheap Super Low Profile Short Stroke Hydraulic Cylinder with Hot selling

Product Description

Product Description

Ultra High Pressure Ultra Low Height Hydraulic Cylinder

Ultra high pressure ultra low height hydraulic cylinder mainly used in space is very limited occasions, for example: Shipbuilding plant host adjustment, lifting of steam turbine maintenance in power plant and so on occasions.

Features

* The top end is provided with an elastic sealing piece to avoid the impurity into the cylinder, extending cylinder life. * Top finite overflow port, when the plunger over stroke, automatic overflow, safe and convenient.

* Overload test pressure is 1.5 times higher than the rated working pressure.

* Compared with the same kind cylinder, the same closed height, there is a longer lift stroke.

* G1/4″ coupler and dust cap included on all models.

Details lmages

Product Specifications

| Item No |

Capacity

(T) |

Max. Working Pressure

(MPa) |

Closed Height A (mm) |

Sroke

(mm) |

Weight

(kg) |

| SOV-STC- 0571 1 | 50 | 150 | 30 | 10 | 2.6 |

Recommend Products

Company Profile

SOV Hydraulic Technoloy (ZheJiang ) Co., Ltd. is a professional manufacturing in hydraulic tools and products, we have been in the industry for more than 20 years. Since the establishment in 1995, we successfully transformed from OEM manufacturer to create our own brand SOV, and our factory has been approved by CE, ISO9001:2008 consecutively. Our Products have been widely used in petrochemical, cement, shipbuilding, steel plant and heavy constructions areas, etc.

We produce and supply Hydraulic tools, such as:

* Hydraulic cylinders, jacks (5-1000ton), single acting and double acting, hollow plunger;

* Hydraulic/ electric /pneumatic torque wrench (100-72000Nm);

* Hydraulic bolt tensioner (100-11486NM);

* Hydraulic pumps, manual and electric type (max up to 3000bar);

* Integrated hydraulic lifting system solutions ( 4-72 points lifting system for house translation or leveling, bridge supporting and tank welding supporting)

* Hydraulic nut and couplings. (M50-Tr1000)

FAQ

Q1: How can contact sales ?

A1: Please click the contact find our website and email address.